April 18, 2018

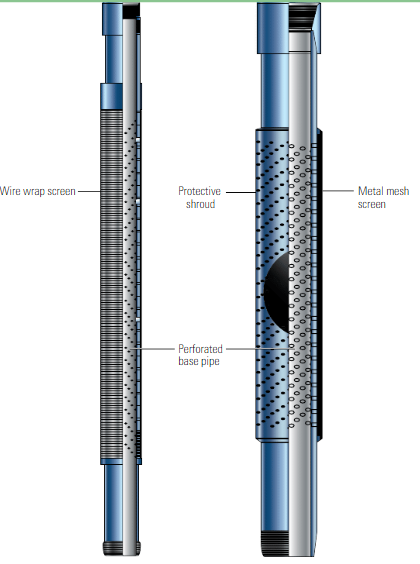

Wire wrapped sand screen filter – TECHNICAL REQUIREMENTS FOR SAND SCREEN OF OIL WELL ON BELUGA FIELD

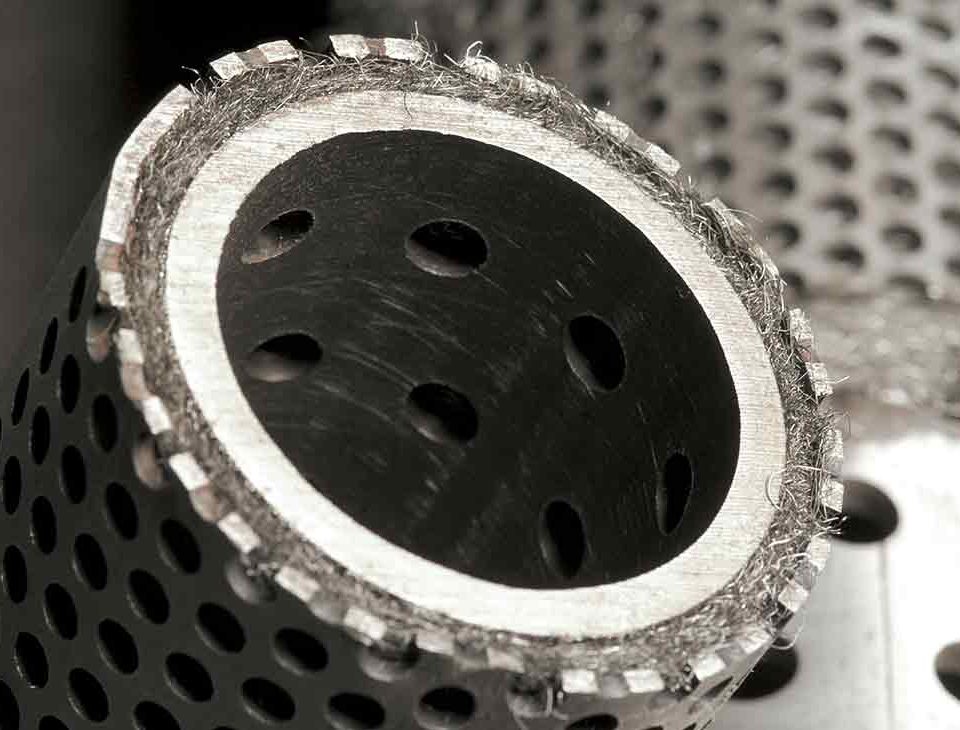

Wire wrapped sand screen filter – TECHNICAL REQUIREMENTS FOR SAND SCREEN OF OIL WELL ON BELUGA FIELD 1. Purpose and area of application Sand screen will be run into oil & gas wells to prevent propant and sand out after hydraulic fracturing jobs (frack pack) in oil well of Beluga […]

-steel-pipe.jpg)