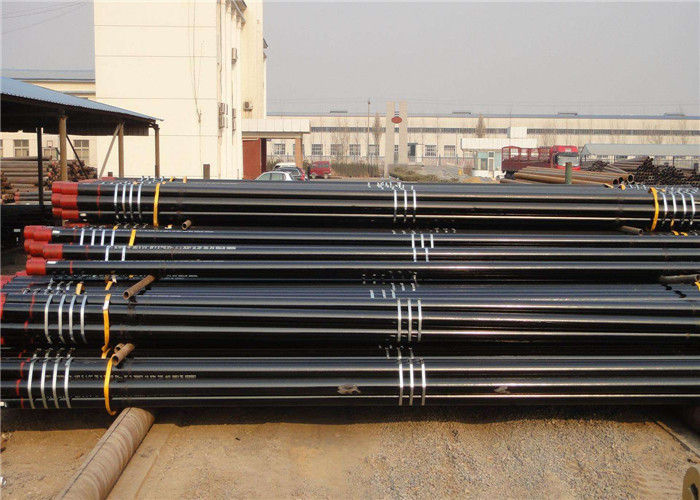

J55 K55 HFW Oil Casing Pipe Research and Development Status and Prospect

June 2, 2023

What is difference between Carbon Steel Seamless Pipe and Welded Steel Pipe Manufacturing Process ?

June 20, 2023ASTM A105 and ASTM A234 are two different material specifications used for manufacturing various components in the piping industry. They have different applications, material properties, and manufacturing processes. Let’s discuss the main differences between them:

ASTM A105

Material: ASTM A105 is a carbon steel material specification for forged and rolled components, such as flanges, fittings, valves, and other pressure-containing parts.

Applications: It is commonly used in piping systems for the petrochemical, oil and gas, and power generation industries.

Material Properties: ASTM A105 has excellent mechanical properties, including high strength, ductility, and toughness. It can withstand high pressure and temperature environments.

Manufacturing Process: Components made from ASTM A105 are typically forged, which involves heating the material and then shaping it using hammers or presses.

ASTM A234

Material: ASTM A234 is a carbon steel and alloy steel material specification for pipe fittings, such as elbows, tees, reducers, and caps.

Applications: It is primarily used in the power generation, petrochemical, and oil and gas industries for the fabrication of pressure-containing parts.

Material Properties: ASTM A234 has different material grades (such as WPB, WPC, and WP11) with varying mechanical properties, depending on the alloying elements and heat treatment process used.

Manufacturing Process: Components made from ASTM A234 are typically formed by welding or seamless processes, which involve shaping the material by bending, extrusion, or other methods without the need for forging.

In summary, ASTM A105 and ASTM A234 are both material specifications used in the piping industry for different types of components. ASTM A105 is mainly used for forged and rolled components, while ASTM A234 is used for pipe fittings. The material properties and manufacturing processes also differ between the two specifications.

-steel-pipe.jpg)