What is the difference between ASTM A105 and ASTM A234?

June 18, 2023

ANSI Flanges and How They Work

July 3, 2023Carbon steel pipes can be manufactured using two different methods: seamless and welded. The main difference between these methods lies in the manufacturing process and the resulting pipe structure. Here’s an overview of both manufacturing processes:

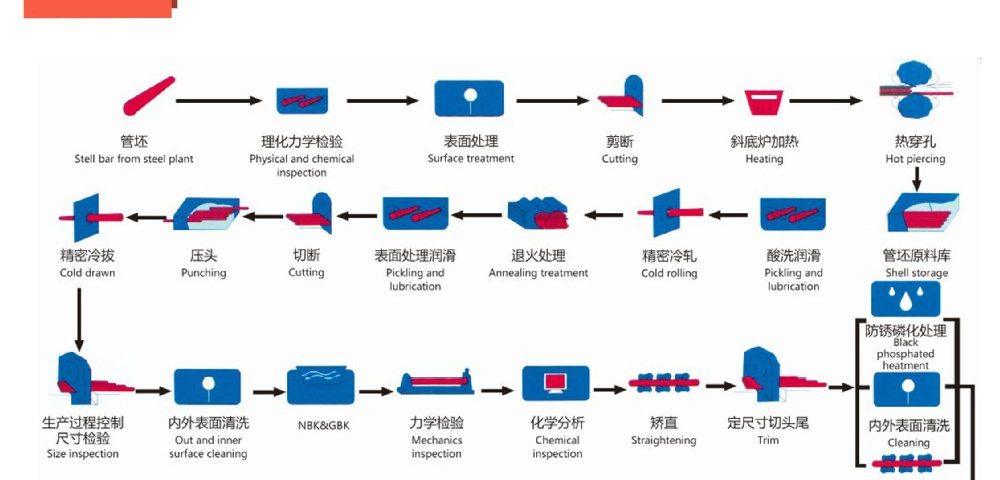

Carbon Steel Seamless Pipe Manufacturing Process:

Seamless pipes are manufactured through a process called hot rolling or cold drawing. In this process, a solid round steel billet is heated to high temperatures and then stretched or pulled over a mandrel or piercing rod to create a hollow tube. The pipe is then further elongated and reduced in size until the desired dimensions are achieved.

Key features:

- No welding involved: Seamless pipes do not have any weld joints, which can result in a more uniform structure and higher strength.

- Better pressure resistance: Due to the absence of weld joints, seamless pipes can better withstand high pressure and are suitable for high-pressure applications.

- Highly precise dimensions: Seamless pipes have more precise dimensions and tighter tolerances compared to welded pipes.

- Higher cost: Seamless pipes are generally more expensive to produce due to their complex manufacturing process.

Welded Steel Pipe Manufacturing Process:

Welded pipes are made by bending and forming flat steel plates or steel coils into a cylindrical shape and then welding the long seam using various welding methods, such as Electric Resistance Welding (ERW), Submerged Arc Welding (SAW), or Gas Tungsten Arc Welding (GTAW). The resulting pipe has a longitudinal seam along its length.

Key features:

- Welded seam: Welded pipes have a visible longitudinal seam, which can be a potential weak point under certain conditions.

- Lower pressure resistance: Due to the presence of a weld seam, welded pipes may have a lower pressure resistance compared to seamless pipes.

- More economical: Welded pipes are generally more cost-effective to produce than seamless pipes, making them a popular choice for low-pressure applications and larger diameters.

- Less precise dimensions: Welded pipes may have less precise dimensions and wider tolerances compared to seamless pipes.

In summary, the main difference between carbon steel seamless pipes and welded steel pipes lies in their manufacturing process and the presence or absence of a weld seam. Seamless pipes are made by stretching a solid steel billet over a mandrel, while welded pipes are made by bending and welding flat steel plates or coils. Seamless pipes offer better pressure resistance and more precise dimensions, while welded pipes are more cost-effective and suitable for low-pressure applications.

-steel-pipe.jpg)