June 29, 2022

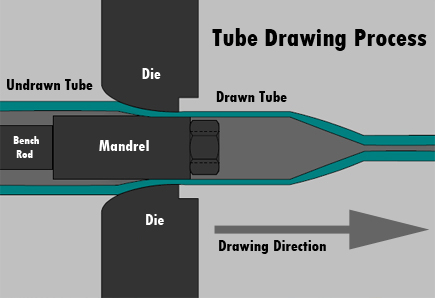

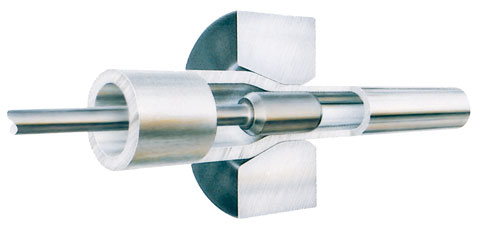

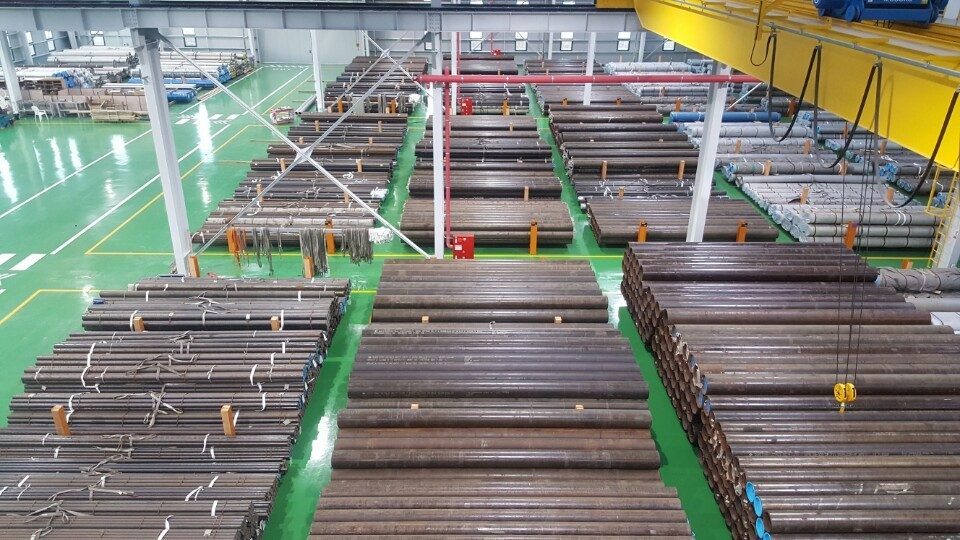

17th International Conference on Metal Forming, Metal Forming 2018, 16-19 September 2018, Toyohashi, Japan Numerical simulation of cold drawing of steel tubes with straight internal rifling Peter Bellaa,*, Roman Durcika, Martin Ridzona, Ludovit Parilak Numerical simulation of cold drawing of steel tubes with straight

-steel-pipe.jpg)