A53 Steel Pipe and Their Differences – A Comprehensive Study

October 8, 2023

Developed Seamless Steel Pipe Products for Boilers

October 21, 2023Technical field

EN10305-1 E235 E255 E355 Precision Seamless Steel Pipe For Automobiles

EN10305-4 Precision Seamless cold drawn Pipes for car

DIN2391 Seamless Cold Drawn Precision Steel Pipes for Automobiles

The present invention relates to a method for manufacturing seamless steel pipes, and in particular to a method for manufacturing special steel pipes for automobile parts.

At present, the existing steel pipes in automobile parts usually use 20# carbon structural steel materials. High-strength steel pipes are mainly obtained through cold working (i.e., cold drawing or cold rolling) deformation, with a tensile strength of 450-550Mpa/c㎡. The elongation index is ≥8%, but there is no requirement for surface roughness in the national standard (GB/T3639-2008). Therefore, when manufacturers manufacture parts, most of them use seamless steel pipes to increase cylindrical cutting (grinding), The inner hole grinding process makes the base material meet the requirements of precision and roughness before proceeding to the next step of processing. The outer surface roughness of the produced steel pipe is greater than 0.4 μm. A grinding process is also required to achieve a high-quality base material steel pipe. Procedure Complex, increasing production costs and reducing production efficiency.

Contents of the invention

The technical problem to be solved by the present invention is to provide a manufacturing method for automobile-specific seamless steel pipes with high tensile strength, good elongation performance and internal and external surface roughness of ≤0.4 μm.

In order to solve the above technical problems, the present invention provides a manufacturing method of seamless steel pipes for automobiles, which method includes the following steps:

Step 1: Round Seamless Steel Pipes forming;

Put the ingredients into the pipe-making mold, and undergo smelting, thermal processing, and cooling to form a Seamless Steel Pipe blank;

Step 2: Perforation processing;

Cut the Seamless Steel Pipes blank with a cutting device, and set the cutting according to the required length of the auto parts. After cutting, it is transported to the heating device via a conveyor rack for full heating. The heating temperature is controlled within the range of 1220°C to 1230°C. The heating device uses a computer A fully automatic temperature closed-loop control system controls the temperature. The capillary Seamless Steel Pipes is heated to prepare for perforation. Heating can transform the capillary Seamless Steel Pipes into a material with sufficient plasticity and low deformation resistance. During the heating process, the structural properties of the steel can be improved, and the Seamless Steel Pipe blank is released. Finally, it has to be pierced by a punching machine. After the tube is bitten by the roller, it first enters the perforation preparation area. It gradually moves forward along the perforation direction so that the circular cross-section changes to an oval. When the tube enters the deformation zone, it reaches 30~50 mm. When the tube blank is in contact with the guide plate, the tube blank continues to move forward. After meeting the plug, the nose of the plug is inserted into the depression on the front end of the tube blank and enters the perforation area. After reaching the cone of the plug, the tube wall is no longer compressed. After that, it enters the expansion and rolling area. After the inner wall of the capillary tube deviates from the top, it enters the capillary rounding area. A cavity called a capillary tube is gradually formed inside the tube blank. The wall thickness of the perforated capillary tube is controlled at: S+0-+0.3mm; after the perforation is completed, Load the pipe material into the steel pipe heading machine, and perform heading processing through the heading machine to ensure the size and concentricity of the steel pipe head. After the heading process, cool the pipe material;

Step 3: First inspection;

The straightness of the capillary tube is ≤30mm/m, the starting length of the capillary tube is 150-170mm, and the wall thickness of the capillary tube is: S+0—+0.3mm. Observe the internal and external surfaces of the capillary tube to ensure that there are no scratches or pits on the surface;

Step 4: First pickling treatment;

According to the proportion of pickling liquid, use hydrochloric acid with a concentration of 15-20%, pickle at room temperature, and pickle for 25 ± 3 minutes. If the iron salt content in the acid tank reaches or exceeds 200 mg/L, change the pickling liquid again and pickle. After washing, rinse with clean water and use phosphorus saponification. The phosphorus saponification temperature is controlled at 60-70°C, the phosphating time is 3-5 minutes, and the saponification time is 9-11 minutes to form a phosphorus and saponification film. After pickling, the capillary tubes are evenly spread on the Blow dry the steel pipe with a fan on a stand tilted 10-12°;

Step 5: First cold drawing treatment;

After chemical treatment, it enters the cold drawing machine for cold drawing processing. A pulling force is applied to one end of the capillary tube to pull out the capillary tube through the mold hole. The hole diameter of the mold is smaller than the diameter of the pipe material. The cold drawing process causes the capillary tube to not only stretch and deform. If there is extrusion deformation, the wall reduction amount in cold drawing production is the wall thickness of the perforated capillary minus 1.0-1.2mm;

Step: 6: Heat treatment;

The purpose of heat treatment of the cold-drawn capillary is to eliminate the cold-drawing stress, restore the plasticity of the material, and refine the metallographic structure of the material;

Step 7: Drill holes at the top of the capillary tube;

At a distance of 18-20cm from the end of the capillary pipe head, use an ∮8mm drill bit to drill the pipe body;

Step 8: Second pickling treatment;

Step 9: Second cold drawing treatment;

The total wall reduction of cold drawing is greater than 1.8mm, and the wall reduction of the finished product is 0.6mm;

Step 10: Straighten and cut the head and tail;

A seventeen-roller straightening machine is used to straighten the capillary pipe. During the straightening process, not only elastic deformation will occur, but also plastic deformation will occur. Therefore, the original longitudinal bending must be changed to achieve longitudinal straightness and make the steel pipe Straightening; then two sets of pipe cutting machines cut the head and tail;

Step 11: Second inspection;

The steel pipe with its head and tail cut passed the second inspection. The straightness of the steel pipe is ≤1.5mm/m, the outer diameter of the steel pipe is D±0.05mm, the inner diameter of the steel pipe is d±0.05mm, the tensile strength of the steel pipe is ≥500Mpa, and the elongation of the steel pipe is ≥8%. , the inner and outer surface roughness of the steel pipe is ≤0.4μm, and the tightness of the steel pipe is tested by an eddy current flaw detection device.

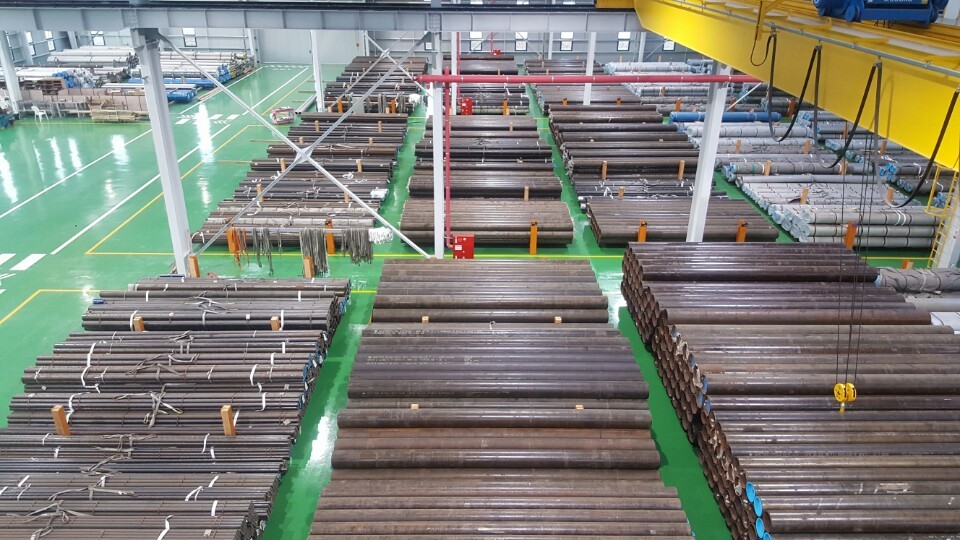

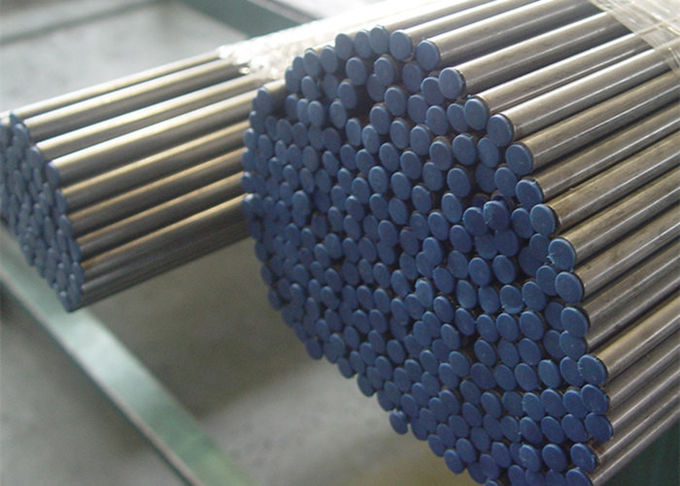

Step 12: Packing and storage;

In steps 4 and 6, in order to ensure the accuracy of parameter concentration and temperature control, an online automatic measurement display system is used for real-time display control.

After adopting the above technical solution, use hydrochloric acid with a concentration of 15-20% and pickle at room temperature. The pickling time is 25±3min. If the iron salt content in the acid tank reaches or exceeds 200mg/L, change the pickling liquid again and saponify with phosphorus. Treatment, the phosphorus saponification temperature is controlled at 60-70°C, the phosphating time is 3-5 minutes, and the saponification time is 9-11 minutes to form a phosphorus and saponification film. After pickling, the capillary tubes are evenly spread on a stand tilted 10-12° , through two pickling phosphorus saponification treatments and two cold drawing treatments, the surface quality of the finished product is improved. During the production process, through secondary inspections, the external or internal quality of the product is ensured, and sawing is used directly without heat treatment and mechanical cutting. This enables the steel pipe to achieve tensile strength ≥ 500Mpa, elongation ≥ 10%, and internal and external surface roughness ≤ 0.4 μm, which meets the requirements for strength, toughness, and surface quality of special steel pipes for automobile parts. At the same time, it meets the requirements of special steel pipes for automobile parts. The technical requirements for the steel pipe base material to be exempted from processing. Experiments have shown that compared with conventional seamless steel pipes, it improves the production efficiency of motor vehicle parts and reduces its production costs.

EN10305-1 E235 E255 E355 Precision Seamless Steel Pipe For Automobiles

| Product Name | EN10305-1 E235 E255 E355 Precision Seamless Steel Pipes |

| Material | E235, E255, E355 |

| Delivery Condition | +C, +LC, +SR, +A, +N |

| Standard | EN10305-1 |

| Size Range | OD: 6-88mm, WT: 1-15mm |

| Application | High precision purpose, auto parts, oil cylinder, etc |

| Round Billet | Bao Steel, Xingcheng Steel, Zhongtian Steel |

| Keyword | Seamless Steel Tube |

| Certificate | TS16949, ISO 9001 |

| HS code | 7304319000 |

| Delivery Time | 45 days |

| Pakcing | Bundles or Woodern Boxes |

| Steel Grade | Chemical Composition | |||||

| Symbol | Material Number | C

Max. |

Si

Max. |

Mn

Max. |

P

Max. |

S

Max. |

| E235 | 1.0308 | 0.17 | 0.35 | 1.20 | 0.025 | 0.025 |

| E255 | 1.0408 | 0.21 | 0.35 | 0.40–1.10 | 0.025 | 0.025 |

| E355 | 1.0580 | 0.22 | 0.55 | 1.60 | 0.025 | 0.025 |

| Steel Grade | +C | +LC | +SR | |||||

| Name | No. | Rm

Mpa |

A

% |

Rm

Mpa |

A

% |

Rm

Mpa |

ReH

Mpa |

A

% |

| E235 | 1.0308 | 480 | 6 | 420 | 10 | 420 | 350 | 16 |

| E255 | 1.0408 | 580 | 5 | 520 | 8 | 520 | 375 | 12 |

| E355 | 1.0580 | 640 | 4 | 580 | 7 | 580 | 450 | 10 |

| Steel Grade | +A | +N | ||||

| Name | No. | Rm

Mpa |

A

% |

Rm

Mpa |

ReH

Mpa |

A

% |

| E235 | 1.0308 | 315 | 25 | 340–480 | 235 | 25 |

| E255 | 1.0408 | 390 | 21 | 440–570 | 255 | 21 |

| E355 | 1.0580 | 450 | 22 | 490–630 | 355 | 22 |

Description of the drawings

Figure 1 is a manufacturing flow chart of the seamless steel pipe of the present invention.

Detailed ways

As shown in Figure 1, the method includes the following steps:

Step 1: Round tube forming;

Put the ingredients into the pipe-making mold, and undergo smelting, thermal processing, and cooling to form a pipe blank;

Step 2: Perforation processing;

Cut the tube blank with a cutting device, and set the cutting according to the required length of the auto parts. After cutting, it is transported to the heating device via a conveyor rack for full heating. The heating temperature is controlled within the range of 1220°C to 1230°C. The heating device uses a computer A fully automatic temperature closed-loop control system controls the temperature. The capillary tube is heated to prepare for perforation. Heating can transform the capillary tube into a material with sufficient plasticity and low deformation resistance. During the heating process, the structural properties of the steel can be improved, and the tube blank is released. Finally, it has to be pierced by a punching machine. After the tube is bitten by the roller, it first enters the perforation preparation area. It gradually moves forward along the perforation direction so that the circular cross-section changes to an oval. When the tube enters the deformation zone, it reaches 30~50 mm. When the tube blank is in contact with the guide plate, the tube blank continues to move forward. After meeting the plug, the nose of the plug is inserted into the depression on the front end of the tube blank and enters the perforation area. After reaching the cone of the plug, the tube wall is no longer compressed. After that, it enters the expansion and rolling area. After the inner wall of the capillary tube deviates from the top, it enters the capillary tube rounding area. A cavity called a capillary tube is gradually formed inside the tube blank. The wall thickness of the perforated capillary tube is controlled at S+0-+0.3mm; after the perforation is completed, the capillary tube will be The pipe material is loaded into the steel pipe heading machine, and is processed by the heading machine to ensure the size and concentricity of the steel pipe head. After the heading process, the pipe material is cooled;

EN10305-4 Precision Seamless cold drawn Pipes for car

Quick Detail:

EN10305-4 Precision Steel Pipes

Seamless cold drawn tubes for hydraulic and pneumatic power systems

Applications:

for Auto industry/for machinery use/Oil Cylinder Tube/Motorcycle shock absorber

Auto shock absorber inner cylinder/Telescopic Cylinders

Size range: O.D.:6-420mm W.T.:1-50mm L:max12000mm

Production: Cold Drawn + Cold Rolling

Steel Grade and Chemical Compositions:

| Steel Grade | C | Si | Mn | P | S | Al | |

| Steel Name | Steel Number | max | max | max | max | max | min |

| E215 | 1.0212 | 0.10 | 0.05 | 0.70 | 0.025 | 0.025 | 0.025 |

| E235 | 1.0308 | 0.17 | 0.35 | 1.20 | 0.025 | 0.025 | – |

| E355 | 1.0580 | 0.22 | 0.55 | 1.60 | 0.025 | 0.025 | – |

| Mechanical properties at room temperature | |||||||||||||

| Steel Grade | Minimum values for the delivery condition | ||||||||||||

| Steel Name | Steel Nubmer | (+Cc) | (+LCc) | (+SR) | (+Ad) | (+N) NBK | |||||||

| Rm Mpa | A % | Rm Mpa | A % | Rm Mpa | ReH Mpa | A % | Rm Mpa | A % | Rm Mpa | ReH Mpa | A % | ||

| E215 | 1.0212 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | 290-430 | 215 | 30 |

| E235 | 1.0308 | 480 | 6 | 420 | 10 | 420 | 350 | 16 | 315 | 25 | 340-480 | 235 | 25 |

| E355 | 1.0580 | 640 | 4 | 580 | 7 | 580 | 450 | 10 | 450 | 22 | 490-630 | 355 | 22 |

Step 3: First inspection;

The straightness of the capillary tube is ≤30mm/m, the starting length of the capillary tube is 150-170mm, and the wall thickness of the capillary tube is: S+0—+0.3mm. Observe the internal and external surfaces of the capillary tube to ensure that there are no scratches or pits on the surface;

Step 4: First pickling treatment;

According to the proportion of pickling liquid, use hydrochloric acid with a concentration of 15-20%, pickle at room temperature, and pickle for 25 ± 3 minutes. If the iron salt content in the acid tank reaches or exceeds 200 mg/L, change the pickling liquid again and pickle. After washing, rinse with clean water and use phosphorus saponification. The phosphorus saponification temperature is controlled at 60-70°C, the phosphorization time is 3-5 minutes, and the saponification time is 9-11 minutes to form a phosphorus and saponification film. In order to ensure the accuracy of the parameter concentration, an online The automatic measurement and display system performs real-time display control. After pickling, the capillary pipes are evenly spread on a stand tilted 10-12°, and the steel pipes are blown dry with a fan;

DIN2391 Seamless Cold Drawn Precision Steel Pipes for Automobiles

| Product Name | DIN2391 Seamless Cold Drawn Precision Steel Pipes |

| Material | ST35, St45, ST52 |

| Delivery Condition | BK, BKW, BKS, GBK, NBK |

| Standard | DIN2391 |

| Size Range | OD: 6-88mm, WT: 1-15mm |

| Application | High precision purpose, auto parts, oil cylinder, etc |

| Round Billet | Bao Steel, Xingcheng Steel, Huai Steel, Zhongtian Steel |

| Keyword | DIN2391 Steel Tube |

| Certificate | TS16949, ISO 9001 |

| HS code | 7304319000 |

| Delivery Time | 45 days |

| Packing | Bundles or Wooden Boxes |

| Steel Grade | Chemical Composition | |||||

| Symbol | Material Number | C

Max. |

Si

Max. |

Mn | P

Max. |

S

Max. |

| ST35 | 1.0308 | 0.17 | 0.35 | ≥0.40 | 0.025 | 0.025 |

| ST45 | 1.0408 | 0.21 | 0.35 | ≥0.40 | 0.025 | 0.025 |

| ST52 | 1.0580 | 0.22 | 0.55 | ≤1.60 | 0.025 | 0.025 |

| Steel Grade | BK | BKW | BKS | |||||

| Name | No. | Rm

Mpa |

A

% |

Rm

Mpa |

A

% |

Rm

Mpa |

ReH

Mpa |

A

% |

| ST35 | 1.0308 | 480 | 6 | 420 | 10 | 420 | 315 | 14 |

| ST45 | 1.0408 | 580 | 5 | 520 | 8 | 520 | 375 | 12 |

| ST52 | 1.0580 | 640 | 4 | 580 | 7 | 580 | 450 | 10 |

| Steel Grade | GBK | NBK | ||||

| Name | No. | Rm

Mpa |

A

% |

Rm

Mpa |

ReH

Mpa |

A

% |

| ST35 | 1.0308 | 315 | 25 | 340–470 | 235 | 25 |

| ST45 | 1.0408 | 390 | 21 | 440–570 | 255 | 21 |

| ST52 | 1.0580 | 450 | 22 | 490–630 | 355 | 22 |

Step 5: First cold drawing treatment;

After chemical treatment, it enters the cold drawing machine for cold drawing processing. A pulling force is applied to one end of the capillary tube to pull out the capillary tube through the mold hole. The hole diameter of the mold is smaller than the diameter of the pipe material. The cold drawing process causes the capillary tube to not only stretch and deform. If there is extrusion deformation, the wall reduction amount in cold drawing production is the wall thickness of the perforated capillary minus 1.0-1.2mm;

Step: 6: Heat treatment;

The purpose of heat treatment for cold-drawn capillary tubes is to eliminate cold-drawing stress, restore material plasticity, and refine the metallographic structure of the material; in order to ensure the accuracy of parameter temperature control, an online automatic measurement and display system is used for real-time display control;

Step 7: Drill holes at the top of the capillary tube;

At a distance of 18-20cm from the end of the capillary pipe head, use an ∮8mm drill bit to drill the pipe body;

Step 8: Second pickling treatment;

Step 9: Second cold drawing treatment;

The total wall reduction of cold drawing is greater than 1.8mm, and the wall reduction of the finished product is 0.6mm;

Step 10: Straighten and cut the head and tail;

A seventeen-roller straightening machine is used to straighten the capillary pipe. During the straightening process, not only elastic deformation will occur, but also plastic deformation will occur. Therefore, the original longitudinal bending must be changed to achieve longitudinal straightness and make the steel pipe Straightening; then two sets of pipe cutting machines cut the head and tail;

Step 11: Second inspection;

The Seamless Steel Pipe with its head and tail cut passed the second inspection. The straightness of the steel pipe is ≤1.5mm/m, the outer diameter of the steel pipe is D±0.05mm, the inner diameter of the steel pipe is d±0.05mm, the tensile strength of the steel pipe is ≥500Mpa, and the elongation of the steel pipe is ≥8%. , the inner and outer surface roughness of the steel pipe is ≤0.4μm, and the tightness of the steel pipe is tested by an eddy current flaw detection device;

-steel-pipe.jpg)