ERW steel pipe

June 26, 2016

SSAW steel pipe

June 26, 2016LSAW Steel Pipe

Manufacturing procedure

In order to supply high quality LSAW steel pipe for our clients, we’ve established a highly sound and strenuous pipe production circulation. After the above-mentioned processes, begin the double-sided submerged arc welding.

Specifications Range

Out Diameter: 219mm-720mm( UOE),406 mm-1625.6 mm( JCOE).

Wall Thickness :max 65mm.

Length:3.0m-18m.

Production technology and equipment

By adopting newest advanced production innovations, we can produce LSAW steel pipe with diameters of over 610mm and wall densities of over 15mm. To be particular, the optimum diameter and wall density of our LSAW steel tube is 2150mm and 30mm respectively.

We utilize extremely advanced hydraulic bending devices to process our big caliber longitudinal immersed arc welded pipes. Our flexing machine is created in double connected structure, which can process pipelines with a maximum length of 16m, and can load an optimal pressure of 1600tons. Through processes, consisting of flexing, butting seams, internal welding, external welding, flattening and correcting the alignment of, our LSAW steel pipes can fulfill the standard requirements of UAS Petroleum Association.

So, if you have any LSAW pipe requirement, please do not hesitate to attempt our products.

Applications

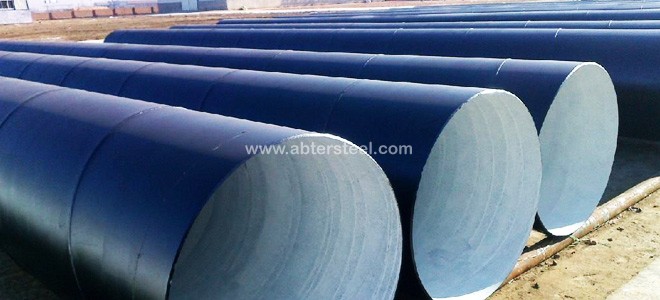

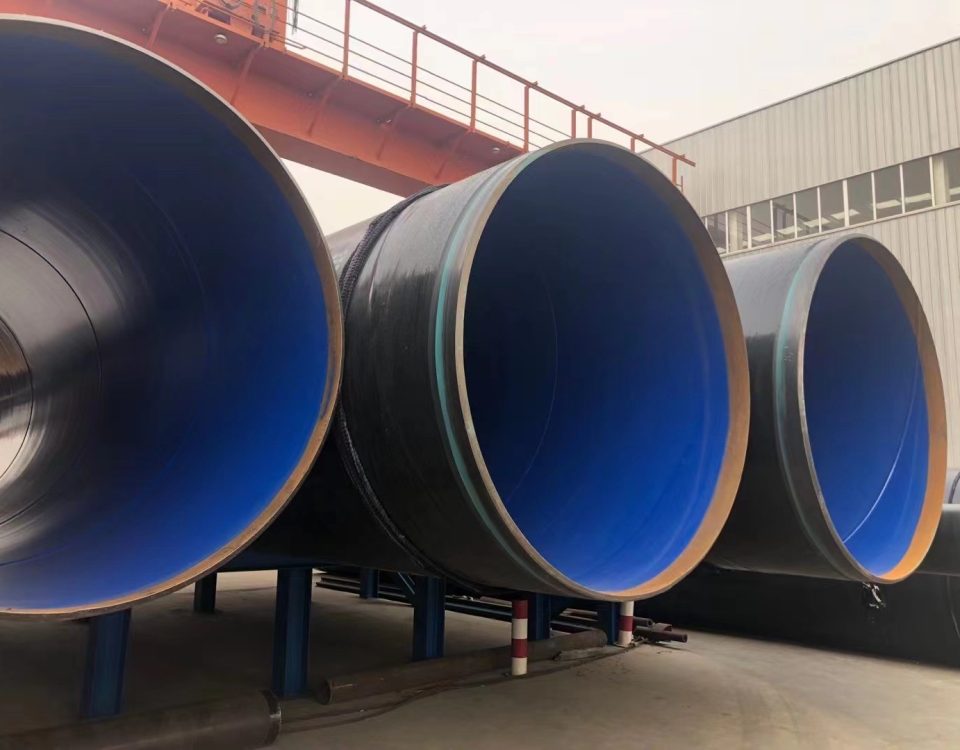

By performing basic nondestructive detections on our LSAW tubes, we ensure that our tubes serve our customers well. Our LSAW steel pipelines are perfect pipelines for massive pipeline engineering, petroleum, water or gas transport and city pipe network building and construction.

Quality assurance

In addition to the LSAW pipe, our company produces a variety of other industrial pipelines, consisting of smooth steel pipe, anticorrosion steel tube, spiral pipes and ERW welded tube. Our CE certified commercial pipelines are well accepted by customers from United States, Canada, Switzerland, Italy, UAE, Syria and more. If you want any commercial pipelines or have any inquires about our pipes, please don’t hesitate to call us.

UOE SAWL PIPES.

The UOE mill features the most sophisticated technology and process, attains high production efficiency, steady product quality and is geared up with complete examination devices.

Prodution Line.

UOE mill adopts U & O forming, the formed pipes are bonded inside through 5 internal welding stations with three wires, and welded outside through 4 external welding stations with three wires. In accordance with various requirements of the customers, the bonded pipe can be broadened either by mechanical or hydrostatic expander to improve dimensional accuracy, and remove recurring tension.

Specifications.

Outside Diameter : Φ508mm- 1118mm (20″- 44″).

Wall Thickness : 6.0-25.4 mm ( 1/4″ -1″ ).

Quality Standards : API 、 DNV 、 ISO 、 DEP 、 EN 、 ASTM 、 DIN 、 BS 、 JIS 、 GB 、 CSA.

Length : 9-12.3 m (30′- 40′).

Grades : API 5L A-X90, GB/T9711 L190-L625.

JCOE SAWL PIPES ( PRESS BENDING ).

Prodution Line.

This is large diameter longitudinal submerged arc welded (SAWL) pipe production line in China. The mill adopts progressive flexing process, featuring evenly distributed forming stress, high uniformity of dimension, boundless sizes variation & broad poduct range, and high flexibility, etc.

Specifications.

Outside Diameter : Φ406mm – 1626mm (16 “-64″). Wall Thickness : 6.0 – 75mm (1/4″- 3”).

Quality Standards : API 、 DNV 、 ISO 、 DEP 、 EN 、 ASTM 、 DIN 、 BS 、 JIS 、 GB 、 CSA.

Length : 3-12.5 m( 10′- 41′).

Grades : API 5L A-X100, GB/T9711 L190-L690.

JCOE SAWL PIPES ( ROLL BENDING ).

Assembly line. This is the first big diameter longitudinal submerged arc bonded (SAWL) pipe production line in China. The mill embraces constant axis twisting J-C-O forming procedure with characteristics of high forming precision and performance along with well balanced distribution of forming stress. The mill has the advantages of large specs and can produce pipes in any size within its production range.

Requirements.

Outdoors Diameter : Φ406mm- 1829mm (16″ – 72″ ).

Wall Thickness : 6.0-30mm ( 1/4″ -11/ 6″ ).

Quality Standards : API 、 DNV 、 ISO 、 DEP 、 EN 、 ASTM 、 DIN 、 BS 、 JIS 、 GB 、 CSA.

Length : 3-12.2 m (10′- 40′ ).

Grades : API 5L A-X80, GB/T9711 L190-L555.

Outside Diameter : Φ406mm – 1626mm (16 “-64”).

Wall Thickness : 6.0 – 75mm (1/4″- 3″).

Quality Standards : API 、 DNV 、 ISO 、 DEP 、 EN 、 ASTM 、 DIN 、 BS 、 JIS 、 GB 、 CSA.

The mill embraces continuous axis contorting J-C-O forming process with characteristics of high forming accuracy and performance as well as balanced distribution of forming stress. The mill has the advantages of broad specs and can produce pipes in any size within its production variety.

7 Comments

Alex Plumbing, your local trusted solution for plumbing repair services responsive, competent, and most reasonable.Alex the plumber goal, is to provide service in a quick and efficient way. Take the necessary time to explain what needs to be done and as well providing answerers to your plumbing questions. My prices are competitive and affordable to fit any need for plumbing repair. Also offer realistic time lines and estimations of costs so that you know exactly what to expect to pay. As well as when to expect the plumbing to be completed. I will continue working on your plumbing repair until you are completely satisfied with the end result. A reliable plumber you can trust with all your plumbing needs. On your next plumbing repair call (239) 404-1701.Thank you for every other informative site. Where else may I get that type of info written in such an ideal way? I’ve a undertaking that I am just now running on, and I’ve been at the glance out for such information.

What is the application of LSAW pipe?

Longitudinal Submerged Arc Welding (LSAW) pipe is a type of steel pipe that is commonly used in the oil and gas industry, and also in infrastructure applications. Below are several primary applications for LSAW pipe:

Oil and Gas Pipeline: The oil and gas industry is the main consumer of LSAW pipes, as they are ideal for transporting fluids like oil, natural gas, and water over long distances. These pipes are known for their high-pressure resistance, making them suitable for these applications.

Structural Applications: LSAW pipes can also be used in piling projects and in bridge construction, where strong, durable materials are needed. The pipes can provide the necessary strength to handle the loads in these applications.

Water Supply Systems: LSAW pipes are also used in water supply systems due to their high strength and resistance to high pressure. They can effectively transport water over long distances without any leakage.

Chemical Industry: In the chemical industry, LSAW pipes are used for the conveyance of chemicals. The pipes are manufactured to withstand the corrosive nature of the chemicals.

Heating, Ventilation, and Air Conditioning (HVAC): LSAW pipes can be used in large-scale HVAC installations where robust and reliable piping is needed.

Renewable Energy Infrastructure: LSAW pipes are used in the installation of infrastructure for renewable energy sources like wind and solar. These pipes are utilized in the construction of wind turbine towers and in the building of structures for solar panels.

What is LSAW welding?

Longitudinal Submerged Arc Welding (LSAW) is a specific type of welding method used in pipe production. As the name suggests, this type of welding is used to create pipes by welding the steel plate from the longitudinal direction.

Here’s a simplified breakdown of the LSAW pipe manufacturing process:

Plate Procurement: The process starts with a single steel plate of the desired thickness.

Plate Preparation: The steel plate is then prepared and cleaned to remove any impurities.

Forming: The prepared plate is then formed into a pipe shape. This is typically done by bending the plate so that the two ends meet, forming a cylindrical shape.

Welding: Now comes the actual welding process. The two ends of the formed plate are joined using a submerged arc welding technique. This type of welding uses a continuously fed electrode that is covered by a layer of flux. The heat generated by the electrical resistance melts the electrode and flux, creating a molten pool that fuses the two ends of the plate together. This process is done in an environment that is shielded by a blanket of granular flux to prevent oxidation or contamination from the surrounding air.

Testing and Finishing: After the welding process, the pipe is tested for quality and any necessary finishing work is done. This includes checking the weld for defects and applying any coatings or treatments needed for the specific application of the pipe.

What is the difference between DSAW and LSAW pipes?

DSAW (Double Submerged Arc Welded) and LSAW (Longitudinal Submerged Arc Welded) pipes both involve the process of Submerged Arc Welding (SAW), but they differ in terms of how the welding is applied.

LSAW Pipes:

LSAW pipes are created by bending and welding steel plates along the longitudinal direction (i.e., along the length or the ‘long’ axis of the pipe). This process results in a single longitudinal seam.

DSAW Pipes:

DSAW process, on the other hand, involves two submerged arc welding passes. The first pass, which forms the first seam, is on the inside of the pipe. The second pass, which forms the second seam, is on the outside of the pipe. Hence, DSAW pipes have two seams, compared to the single seam of the LSAW pipes.

This double welding process increases the strength and integrity of the pipe, making it suitable for high pressure or critical applications.

However, it’s important to note that sometimes the term “DSAW” is also used to refer both to pipes with two seams (double submerged arc welding) and pipes with one seam (longitudinally submerged arc welding). This can sometimes cause confusion, so it’s always good to check what exactly is meant by “DSAW” in a given context.

In terms of application, both LSAW and DSAW pipes are used in similar environments such as in oil, gas, and water transportation, as well as in structural and construction projects.

What is the difference between DSAW and LSAW?

The specified yield strength of A500 Grade C (the most commonly available grade) is 46 ksi. The specified yield strength of A53 Grade B is 35 ksi. That’s over a 30% increase in yield strength. Therefore, A500 round HSS have greater strength-to-weight ratios than A53 pipes

The difference between DSAW and LSAW is that DSAW pipes have a seam weld in the inside and outside of the pipe, while LSAW pipes have a single seam weld on the outer surface, longitudinal or cross sectional. LSAW and SSAW employ the same manufacturing technology – JCOE process.