Casing Coupling,Tubing Coupling,PUP JONIT

June 26, 2016

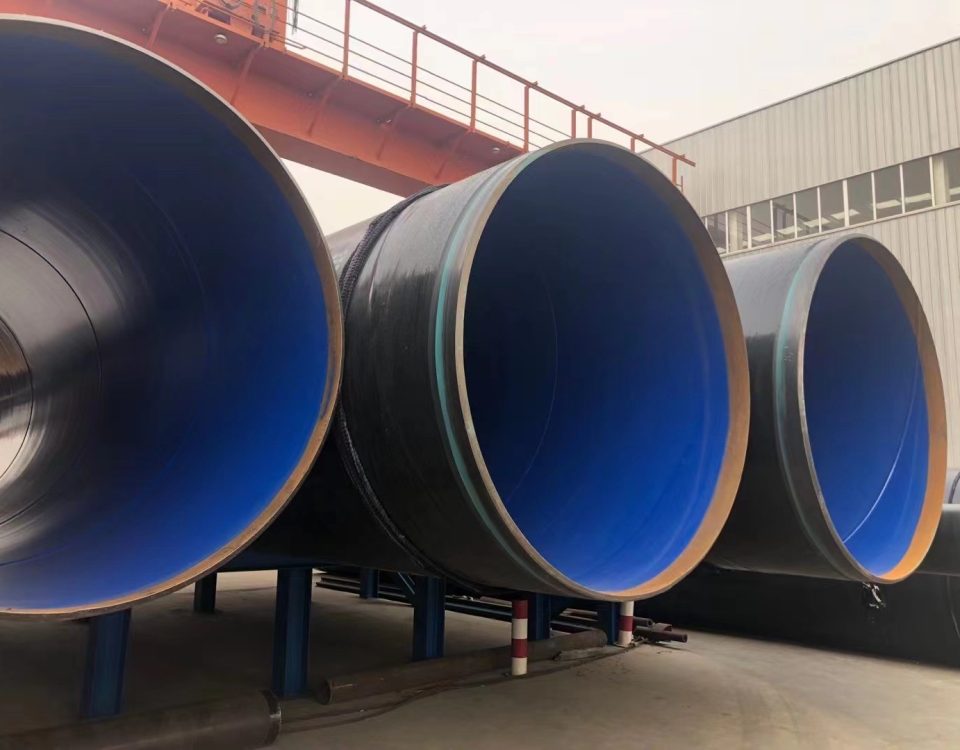

LSAW steel pipe

June 26, 2016The ERW steel pipe is also known as straight joint pipe. According to the wall density, the bonded tube is categorized into typical types and thick-walled types. We can offer items with personalized wall thickness according to customers’ particular requirement with a thickness deviation of no more than 0.25 mm.

With sizes between 1/2 inch and 24 inch, our ERW steel pipes go through rigorous examinations and tests, so about make sure the welding quality, external size precision, ovality, cut lengths, pipe end quality, wall density tolerance, and packaging quality are all conforming to API5L, ASTMA53, GB/T9711.1, or GB/T3091 standards. Also, we can make the item according to the standard needed by customers.

Technical Specifications

Size Range: 1/2 inch ~ 24 inch (21.3 ~ 610mm).

Wall Thickness: 0.5 ~ 16mm.

Requirement: API 5L, ASTM A53, GB/T9711.1, GB/T3091.

Steel Grade: GR.A, GR.B, X42, X46, X52, X56, X60, X65, X70.

End surface: Plain end, bevel end, thread, coupling, plastic cap.

Pipe finish: Black vanish, bare, clear oil.

erw steel pipe process

1. Uncoiling.

2. Strip Leveling.

3. End Cutting.

4. End Shearing and Welding.

5. Accumulator.

6. Forming.

7. Induction Welding.

8. Joint Heat Treatment.

9. air/Water Cooling.

10. Seam/Body UT.

11. Straightening and sizing.

12. Cutting.

13. Visual and Dimension Inspection.

14. Hydrostatic Test.

15. End Facing and Chamfering.

16. Flattening Testing.

17. Marking.

18. Length-Measuring and Weighing.

19. Seam/End UT.

20. Coating.

21. Storage.

The ERW steel pipe is also understood as straight seam pipe. According to the wall density, the bonded tube is categorized into common types and thick-walled types. We can offer items with customized wall density according to customers’ specific requirement with a thickness discrepancy of no more than 0.25 mm.

With sizes between 1/2 inch and 24 inch, our ERW steel pipes undergo strict inspections and tests, so as to make sure the welding quality, external diameter accuracy, ovality, cut lengths, pipe end quality, wall thickness tolerance, and packaging quality are all conforming to API5L, ASTMA53, GB/T9711.1, or GB/T3091 requirements.

| Specifications | Range |

| Out Diameter | 1/8 inch to 24 inch |

| Wall Thickness | max 26.5mm |

| Length | 3.0m-18m |

Tolerance of Outside Diameter

| Standard | Out Diameter | Tolerance of Pipe End | Tolerance of Pipe Body |

| API 5L | 219.1~273.1 | +1.6mm, -0.4mm | ±0.75% |

| 274.0~320 | +2.4mm, -0.8mm | ±0.75% | |

| 323.9~457 | +2.4mm, -0.8mm | ±0.75% | |

| 508 | +2.4mm, -0.8mm | ±0.75% | |

| 559~610 | +2.4mm, -0.8mm | ±0.75% |

Tolerance of Wall Thickness

| Standard | Grade | Out Diameter | Wall Thickness |

| API 5L | A | 219.1~457 | +15%, -12.5% |

| B | 508~610 | +17.5%, -12.5% | |

| X42-X80 | 508~610 | +19.5%, -8% |

Chemical Analysis and Mechanical Properties

| Standard | Class | Grade | Chemical Analysis(%) | Mechanical Properties(min)(Mpa) | ||||

| C | Mn | P | S | Tensile Strength | Yield Strength | |||

| API 5L | PSL1 | B | 0.26 | 1.20 | 0.030 | 0.030 | 414 | 241 |

| X42 | 0.26 | 1.30 | 0.030 | 0.030 | 414 | 290 | ||

| X46 | 0.26 | 1.40 | 0.030 | 0.030 | 434 | 317 | ||

| X52 | 0.26 | 1.40 | 0.030 | 0.030 | 455 | 359 | ||

| X56 | 0.26 | 1.40 | 0.030 | 0.030 | 490 | 386 | ||

| X60 | 0.26 | 1.40 | 0.030 | 0.030 | 517 | 414 | ||

| X65 | 0.26 | 1.45 | 0.030 | 0.030 | 531 | 448 | ||

| X70 | 0.26 | 1.65 | 0.030 | 0.030 | 565 | 483 | ||

| PSL2 | B | 0.22 | 1.20 | 0.025 | 0.015 | 414 | 241 | |

| X42 | 0.22 | 1.30 | 0.025 | 0.015 | 414 | 290 | ||

| X46 | 0.22 | 1.40 | 0.025 | 0.015 | 434 | 317 | ||

| X52 | 0.22 | 1.40 | 0.025 | 0.015 | 455 | 359 | ||

| X56 | 0.22 | 1.40 | 0.025 | 0.015 | 490 | 386 | ||

| X60 | 0.22 | 1.40 | 0.025 | 0.015 | 517 | 414 | ||

| X65 | 0.22 | 1.45 | 0.025 | 0.015 | 531 | 448 | ||

| X70 | 0.22 | 1.65 | 0.025 | 0.015 | 565 | 483 | ||

| X80 | 0.22 | 1.85 | 0.025 | 0.015 | 621 | 552 | ||

19 Comments

Exactly what is the difference between erw pipeline as well as seamelss pipes?

I like the actual beneficial info you supply in your content.

I’ll save their weblog and look again below regularly. I’m relatively positive I will be informed a lot of

brand new things the proper below! Best of luck for the next!

Difference between ms pipe and erw pipe?

MS pipe refers to mild steel pipe and ERW pipe is electric resistance welding pipe. The difference is ERW is made of very fine hard steel, while MS (black pipe) is made of malleable steel.

How to identify seamless steel pipe and Erw welded pipe??

ERW steel pipe:You can see the weld straight down the length of the pipe.

Seamless steel pipe : You can’t see the welded straight length…on the steel pipe…

If it is ASTM A53, Type S means seamless.

Type F is furnace but welded,

Type E is Electrical resist welded.

To identify that a pipe supplied is seamless or ERW, Simply read the stencil on the side of the steel pipe.

Put H2So4 or HNo3 acid on the edges.

It is only possible when the pipe ends are open. You can do a Macro-test.

If it is welded, it will show the weld boundries. If not welded it will not show edges.

what is the Process erw pipe?

Process erw pipe is specially designed for particular applications to ensure that it will meet health and safety standards, in addition to suiting the needs of a given manufacturing process.

Process erw pipe is the system of pipes transport process fluids, such as industrial gases, fuels or water, around an industrial facility involved in the manufacture of products or the generation of power.

Is this the erw steel pipe low carbon steel or high carbon steel ?

Each unit of ERW PIPE is composed of low-carbon, fine-grain steel of the highest quality available in the industry.

What is api for short?

API American Petroleum Institute standard –API (American Petroleum Institute) abbreviation.

While manufacturing ERW steel pipes, only high-quality, continuous-cast, fully killed, control-rolled, fine-grain, low-carbon steel is used. High performance ERW steel pipes and tubing possess high strength corrosion resistance, high deformability, high strength and high toughness.

Is there an oil casing made of welded ERW pipe?

Yes, of course.

My Company is Quality Seamless Casing Pipe manufacturers & exporter. ABTER STEEL SALES Hot Rolled Seamless Casing Pipe Non – Alloy API 5CT K55 J55 N80 For Oil / Gas Drilling from China manufacturer.

What is the erw production process?

The first process of producing Erw Tube is hoop slitting hot coil in a fixed width. After welding & removing bead through forming roll,the form of Erw Tube is sized at the sizing roll within the common difference,cut with lighteousness foot,going through roughing tube inspection and having degree of straight collected at straightner.The end section of tube goes through water pressure testing for correcting the pressure according to the size after being faced plain or bevel to its use.

Structurals and Standard Pipe : TMK produces hot finished structural hollow sections of non-alloy and fine grain steel according to the standard DIN EN 10210-1,2 and cold-formed seamless and welded carbon steel structural tubing in rounds in accordance with ASTM A500.