differentce between ERW pipe and EFW pipe

October 4, 2016

ASTM/ASME A252/SA252 Grade 2 Piling steel Pipe

October 12, 2016ASTM A53/A53M Standards Specification for Pipe, NPS 1/4 INCH – 30 INCH ,Schedules 10 -160, STD, XH and XXH Welded and Seamless , Black and Hot-Dipped, Zinc-Coated

ASTM A53 VS A153 steel

ASTM A53 pipe covers Welded and also smooth, Black and also Hot-Dipped Galvanized nominal (average) wall surface pipeline for curling, bending, flanging and also other unique objectives and appropriates for welding. Continuous-Welded pipeline is not intended for flanging. Objective for which pipeline is planned should be specified on order.

Of all, we have to differentiate the distinction between ASTM A53 and also ASTM A153. Many galvanizers are familiar with A153, Requirement Specification for Zinc Layer (Hot-Dip) on Iron as well as Steel Hardware. We need to be mindful when we hear somebody ask regarding A53 which is a totally various requirements. As a matter of fact, ASTM titles A53 as Conventional Requirements for Pipeline, Steel, Black as well as Hot-Dipped, Zinc-Coated, Welded as well as Seamless. Area 17 of ASTM A53, titled Galvanized Pipe, specifies demands for galvanized pipeline bought under this requirements. The section requires the pipeline to be hot-dip galvanized with a grade of zinc complying with Specification B6, Criterion Requirements for Zinc, as well as provides needs for weight per unit area of the finishing.

ASTM A53 does not have the demands for the coating, appearance, or adherence of the galvanized layer that exist in ASTM A123, Requirement Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Product. The weight each system area of the covering called for in ASTM A53 is precisely the same as the minimum layer thickness needs of the very same product in ASTM A123. As a result, ASTM A123 is an extra extensive and extensive spec in relation to the galvanized finishing. It will certainly fulfill the requirements of section 17 of ASTM A53 if a steel pipe is galvanized in accordance to ASTM A123.

1. SIZES

1/2″– 12″ some limitations dependent after quality. Sizes up to 26″ OD are offered on restricted basis.

This spec covers smooth as well as bonded black as well as hot-dipped galvanized steel pipe in NPS 1/8 to NPS 26 [DN 6 to DN 650] (Note 1), comprehensive, with nominal wall thickness (Note 2) as given up Table X2.2 as well as Table X2.3. It shall be allowable to provide pipeline having various other dimensions provided that such pipe abide by all various other demands of this specification. When specified by the purchaser, supplemental requirements of an optional nature are supplied and also will use just.

Keep in mind 1– The dimensionless designators NPS (nominal pipeline dimension) [DN (diameter nominal)] have been replaced in this spec for such typical terms as “small diameter,” “dimension,” as well as “small size.”

2. Criterion Weight

Single Random 16 22. 5% might be jointers. , if Ordinary Ends 5% may be 12 16.

.

Dual Random Shortest Size 22, minimum ordinary for order 35.

Additional Dual as well as solid Bonus Strong

Single Random 12 -22. 5% could be 6 12.

Dual Random (XS and also lighter) Quickest Length 22, minimal ordinary for order 35.

Lengths longer compared to single random with wall surface thicknesses heavier compared to XS based on arrangement.

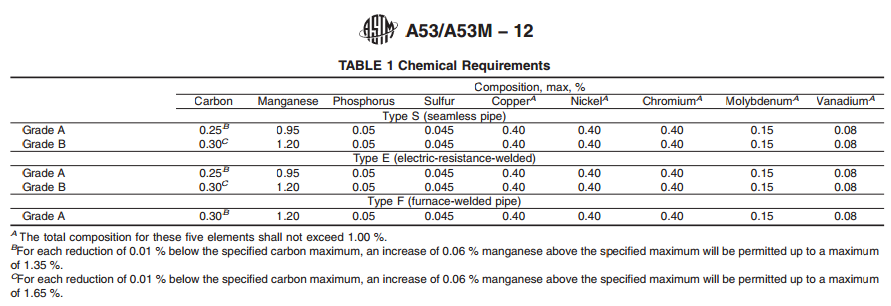

3. Chemical Requirements:

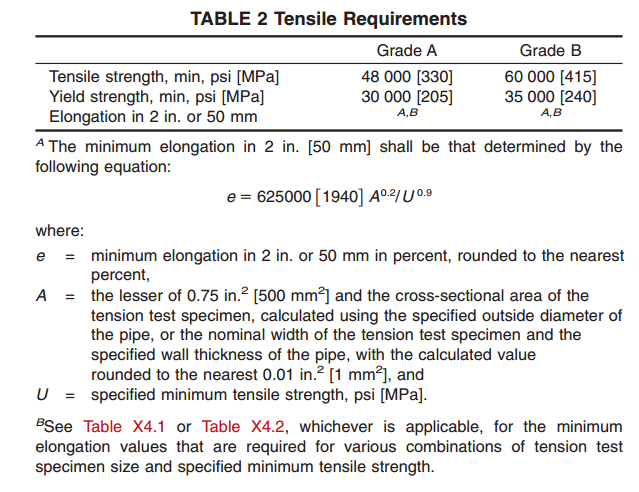

4. Tensile Requirements:

Tensile Test– Transverse needed on ERW for NPS 8 and also large. Sending Test (Cold)– Sexually Transmitted Disease as well as XS-NPS 2 and also under XXS-NPS 1 1/4 as well as under.

4. 1 Hydrostatic Checking

Hydrostatic assessment examination stress for ordinary end as well as threaded and also coupled pipe are specified. Hydrostatic stress shall be maintained for not less than 5 seconds for all sizes of smooth as well as electric-resistance-weld pipe.

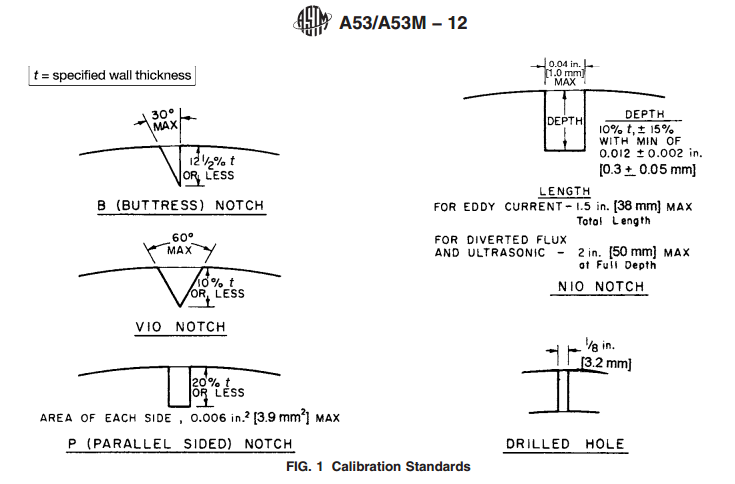

5. Calibration Standards:

6. Materials as well as Manufacture

The steel for both smooth and also bonded pipeline will be made by several of the complying with procedures: open-hearth, electric heating system, or basic-oxygen. The weld joint of electric-resistance bonded pipe in Grade B shall be warmth dealt with after welding.

7. ATTRIBUTES

Developed for curling, flexing and flanging, A53 carbon steel pipe appropriates for welding. The qualities denote particular chemical and mechanical residential or commercial properties and ought to be kept in mind in option.

Note 2– The term small wall density has actually been designated for the purpose of practical classification, existing in name only, as well as is made use of to differentiate it from the actual wall density, which could differ over or under the nominal wall thickness.

8. ASTM A53 PIPE TYPES

The list below types and also qualities of A53 pipeline are covered within this specification:

Kind F– Furnace-butt-welded, continual welded Quality A.

Type E- Electric-resistance-welded, Grades An and also B.

Kind S- Seamless, Grades An and B.

9. APPLICATIONS

ASTM A53 pipeline is planned for mechanical as well as pressure applications and also is also appropriate for ordinary usages in vapor, water, gas and also air lines.

Keep in mind 3– See Appendix X1 for interpretations of sorts of pipe.

1.3 Pipe purchased under this specification is planned for mechanical as well as pressure applications as well as is likewise acceptable for common usages in heavy steam, air, gas, and also water lines. It is suitable for welding, as well as suitable for forming operations involving coiling, bending, and also flanging, based on the adhering to certifications:

1.3.1 Type F is not intended for flanging.

1.3.2 If Kind S or Type E is needed for close coiling or cold flexing, Grade A is the favored grade; nevertheless, this is not meant to forbid the chilly bending of Quality B pipe.

1.3.3 Type E is provided either nonexpanded or cold expanded at the choice of the maker.

Requirement Requirements for Pipeline, Steel, Black and also Hot-Dipped, Zinc-Coated, Welded as well as Seamless. This requirements covers smooth and welded hot-dipped and also black galvanized steel pipe.

7 Comments

I was just looking at your ASTM A53/A53M Standards Specification for Pipe, NPS 1/4 INCH – 30 INCH ,Schedules 10 -160, STD, XH and XXH Welded and Seamless site and see that your website has the potential to get a lot of visitors.

What is the difference between ASTM A106 Grade B and ASTM A53?

A53 pipe is best suited for transport of air, water, steam and oil in low- and medium pressure applications across the industrial spectrum. It’s also commonly used as structural steel. A106 pipe is formulated specifically for high-temperature and high-pressure service, usually in power generation applications.

What is ASTM A53 pipe used for?

ASTM A53 and ASME SA53 is intended for mechanical and pressure applications and is also acceptable for ordinary uses in steam, water, gas and air lines. It is suitable for welding and for forming operations involving coiling, bending, and flanging, subject to certain qualifications.

What is ASTM A53 standard pipe sizes?

A53 Pipe Specifications

Sizes: 1/8” NPS to 26” OD.

Schedules: S/10, S/20, S/40, STD, S/60, S/80, XH, S/100, S/120, S/140, S/160 and XXH.