Effect of Groove Designs on Residual Stress and Transverse Shrinkage in GMAW and PGMAW of A333 Seamless Steel Pipes

June 29, 2022

Part 1. How to control the deformation of precision seamless tubes during the cold drawing process

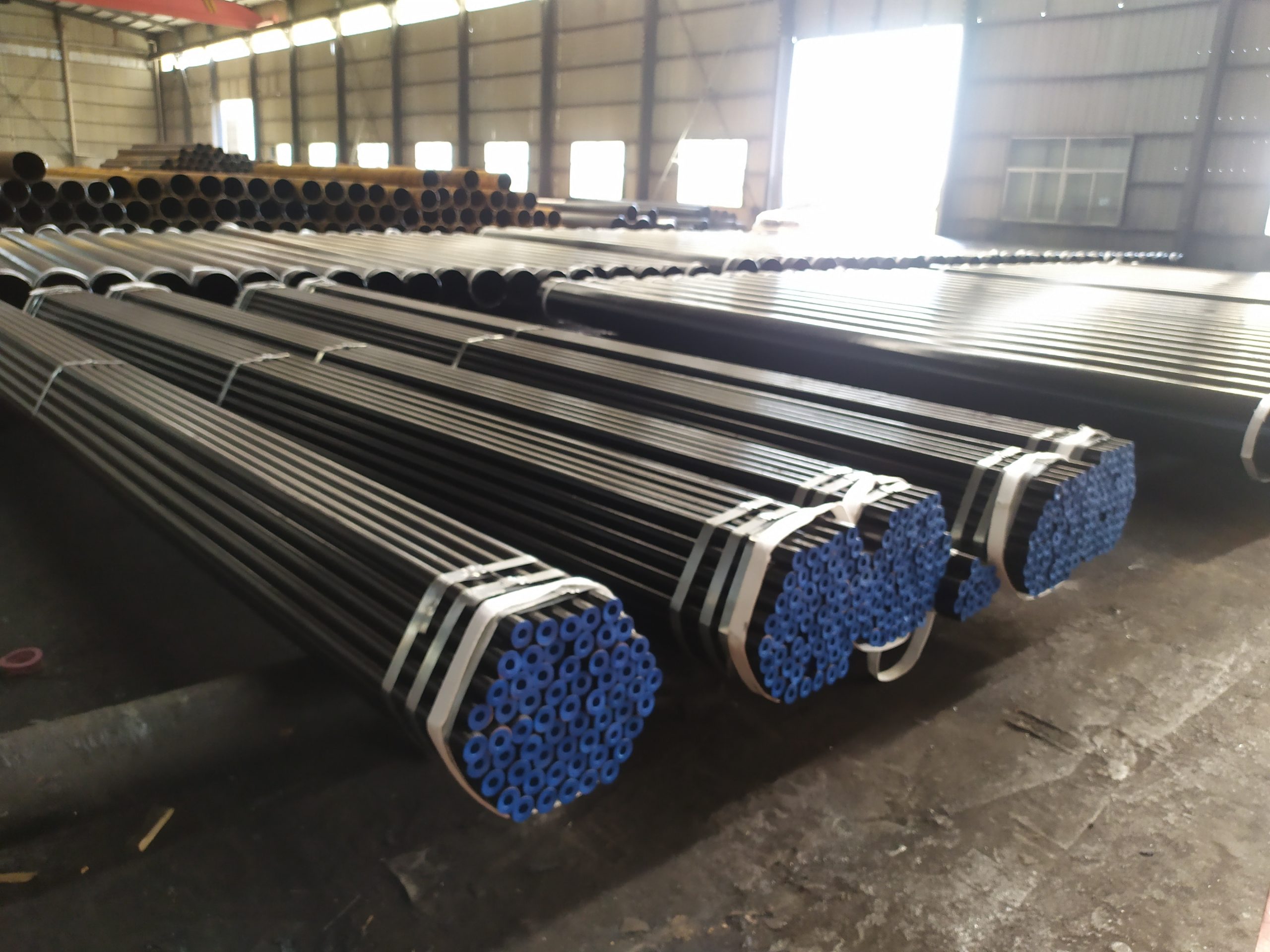

July 8, 2022According to different production methods, it is divided into hot-rolled pipe, cold-rolled pipe, cold-drawn pipe, extruded pipe, pipe jacking, etc., all of which have their own process regulations. The materials are ordinary and high-quality carbon structural steel (Q215-A~Q275-A and 10~50 steel), low alloy steel (09MnV, 16Mn, etc.), alloy steel, stainless acid-resistant steel, etc. According to the use, it is divided into two categories: general use (for water, gas pipelines and structural parts, mechanical parts) and special (for boilers, geological exploration, bearings, acid resistance, etc.).

Seamless steel pipes are widely used. General-purpose seamless steel pipes are rolled from ordinary carbon structural steel, low-alloy structural steel or alloy structural steel, with the largest output, and are mainly used as pipelines or structural parts for conveying fluids. .2. According to different uses, it is divided into three types of supply: a. According to chemical composition and mechanical properties; b. According to mechanical properties; c. According to hydraulic test. Steel pipes supplied according to categories a and b, if they are used to withstand liquid pressure, shall also be subjected to a hydrostatic test. 3. There are many kinds of seamless pipes for special purposes, such as seamless pipes for boilers, seamless pipes for chemical power, seamless pipes for geological use and seamless pipes for petroleum.

Seamless steel pipes have hollow sections and are widely used as pipelines for transporting fluids, such as pipelines for transporting oil, natural gas, gas, water and certain solid materials. Compared with solid steel such as round steel, the steel pipe is lighter in weight when the bending and torsional strength is the same, and is an economical section steel.

It is widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipes, automobile transmission shafts, bicycle frames and steel scaffolding used in construction. The use of steel pipes to make ring parts can improve material utilization, simplify manufacturing processes, save materials and processing Man-hours have been widely used to manufacture steel pipes.

Production Process

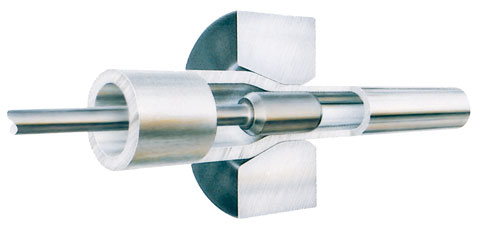

①The main production process of hot-rolled seamless steel pipe (△main inspection process):

Tube blank preparation and inspection△→tube blank heating→piercing→tube rolling→steel reheating→fixed (reduced) diameter→heat treatment△→finished pipe straightening→finishing→inspection△ (non-destructive, physical and chemical, Taiwan inspection)→warehousing

②The main production process of cold-rolled (drawn) seamless steel pipe:

Billet preparation→pickling lubrication→cold rolling (drawing)→heat treatment→straightening→finishing→inspection

The production process of general seamless steel pipes can be divided into two types: cold-drawing and hot-rolling. The production process of cold-rolled seamless steel pipes is generally more complicated than that of hot rolling. In the sizing test, if the surface does not respond to cracks, the round tube will be cut by a cutting machine and cut into a billet with a length of about one meter. Then enter the annealing process, annealing should be pickled with acidic liquid, and pay attention to whether there is a lot of blistering on the surface during pickling. If there is a lot of blistering, it means that the quality of the steel pipe does not meet the corresponding standard. In appearance, the cold-rolled seamless steel pipe is shorter than the hot-rolled seamless steel pipe. The wall thickness of the cold-rolled seamless steel pipe is generally smaller than that of the hot-rolled seamless steel pipe, but the surface looks brighter than the thick-walled seamless steel pipe, and the surface is not too much. Much rough, and the caliber doesn’t have too many burrs.

The delivery state of hot-rolled seamless steel pipe is generally that the hot-rolled state is delivered after heat treatment. After the quality inspection, the hot-rolled seamless steel pipe must be strictly hand-selected by the staff. After the quality inspection, the surface should be oiled, followed by several cold-drawing experiments, and the perforation experiment should be carried out after the hot-rolling treatment. If the diameter of the perforation is too large, it should be straightened and corrected. After straightening, it is transferred to the flaw detector by the conveyor for flaw detection experiment, and finally labelled and arranged in specifications, and then placed in the warehouse.

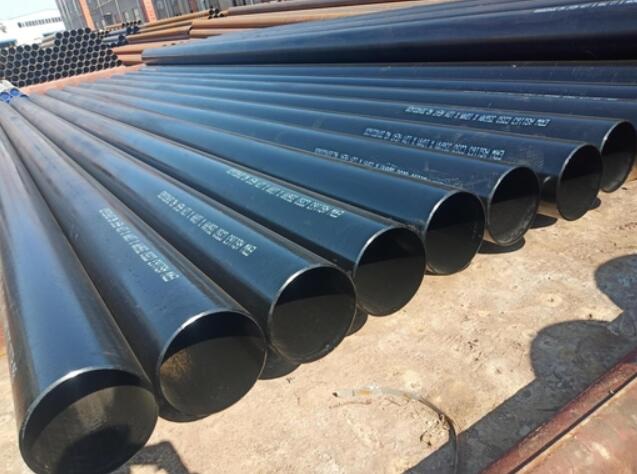

Round tube blank→heating→piercing→three-roller skew rolling, continuous rolling or extrusion→tube removal→sizing (or reducing)→cooling→straightening→hydrostatic test (or flaw detection)→marking→storage seamless steel pipe It is made of steel ingots or solid tube blanks through perforation to make capillaries, and then hot-rolled, cold-rolled or cold-drawn. The specifications of seamless steel pipes are expressed in millimeters of outer diameter * wall thickness.

The outer diameter of the hot-rolled seamless pipe is generally greater than 32mm, the wall thickness is 2.5-200mm, the outer diameter of the cold-rolled seamless pipe can reach 6mm, the wall thickness can reach 0.25mm, and the thin-walled pipe can reach 5mm. Rolling has higher dimensional accuracy than hot rolling.

Generally, seamless steel pipes are made of 10, 20, 30, 35, 45 and other high-quality carbon steel 16Mn, 5MnV and other low-alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB and other combined steel hot-rolled or cold-rolled. Seamless pipes made of low carbon steel such as 10 and 20 are mainly used for fluid transportation pipelines. 45, 40Cr and other medium carbon steel seamless pipes are used to manufacture mechanical parts, such as the stressed parts of automobiles and tractors. Generally, seamless steel pipes are used to ensure strength and flattening tests. Hot-rolled steel pipes are delivered in hot-rolled or heat-treated state; cold-rolled steel pipes are delivered in heat-treated state.

Hot rolling, as the name implies, has a high temperature of the rolled piece, so the deformation resistance is small, and a large amount of deformation can be achieved. Taking the rolling of steel plates as an example, the thickness of the continuous casting slab is generally about 230mm, and after rough rolling and finishing rolling, the final thickness is 1~20mm. At the same time, due to the small width-to-thickness ratio of the steel plate, the dimensional accuracy requirements are relatively low, and the plate shape problem is not easy to occur, and the main control is to control the crown. For those with organizational requirements, it is generally realized by controlled rolling and controlled cooling, that is, controlling the opening temperature and final rolling temperature of finishing rolling. Round tube billet → heating → perforation → heading → annealing → pickling → oiling (copper plating) → Multi-pass cold drawing (cold rolling) → billet tube → heat treatment → straightening → hydraulic test (flaw detection) → marking → storage.

Mechanical performance index

The mechanical properties of steel are important indicators to ensure the end-use properties (mechanical properties) of steel, which depend on the chemical composition and heat treatment system of the steel. In the steel pipe standard, according to different use requirements, the tensile properties (tensile strength, yield strength or yield point, elongation), hardness and toughness indicators, as well as high and low temperature properties required by users are specified.

① Tensile strength (σb)

During the tensile process, the maximum force (Fb) that the sample bears at the time of breaking, divided by the original cross-sectional area (So) of the sample (σ), is called tensile strength (σb), and the unit is N/mm2 (MPa). It represents the maximum ability of a metal material to resist damage under tension.

②Yield point (σs)

For metal materials with yielding phenomenon, the stress at which the specimen can continue to elongate without increasing the force (remaining constant) during the tensile process is called the yield point. If the force decreases, the upper and lower yield points should be distinguished. The unit of yield point is N/mm2 (MPa).

Upper yield point (σsu): the maximum stress before the specimen yields and the force drops for the first time; lower yield point (σsl): the minimum stress in the yield stage when the initial transient effect is ignored.

③Elongation after fracture (σ)

In a tensile test, the percentage of the increase in the gauge length of the specimen after it is broken is called the elongation. It is represented by σ and the unit is %. The calculation formula is: σ=(Lh-Lo)/L0*100%

④ Section shrinkage (ψ)

In the tensile test, the percentage of the maximum reduction of the cross-sectional area at the reduced diameter of the specimen after the specimen is broken is called the reduction of the area. It is expressed in ψ and the unit is %. Calculated as follows:

⑤Hardness index

The ability of a metal material to resist the indentation of a hard object is called hardness. According to different test methods and scope of application, hardness can be divided into Brinell hardness, Rockwell hardness, Vickers hardness, Shore hardness, microhardness and high temperature hardness. For pipes, there are three commonly used hardnesses: Brinell, Rockwell and Vickers.

- Brinell hardness (HB)

Use a steel ball or cemented carbide ball with a certain diameter to press into the surface of the sample with the specified test force (F), remove the test force after the specified holding time, and measure the indentation diameter (L) on the surface of the sample. The Brinell hardness value is the quotient of the test force divided by the surface area of the indentation spherical. Expressed in HBS (steel ball), the unit is N/mm2 (MPa).

The measurement of Brinell hardness is more accurate and reliable, but generally HBS is only suitable for metal materials below 450N/mm2 (MPa), not suitable for harder steel or thinner plates. Among the steel pipe standards, Brinell hardness is the most widely used, and the hardness of the material is often expressed by the indentation diameter d, which is both intuitive and convenient.

Example: 120HBS10/1000/30: Indicates that the Brinell hardness value measured by a steel ball with a diameter of 10mm under the action of a test force of 1000Kgf (9.807KN) for 30s (seconds) is 120N/mm2 (MPa).