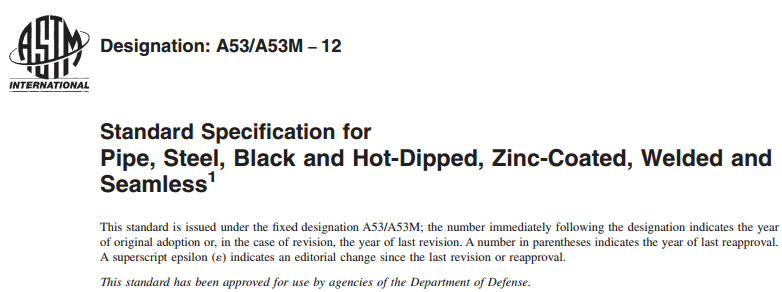

ASTM A53/A53M Standards Specification for Pipe, NPS 1/4 INCH – 30 INCH ,Schedules 10 -160, STD, XH and XXH Welded and Seamless

October 10, 2016

Taiwan steel exporters imposed anti-dumping tariffs in Thailand

October 14, 2016Abter Steel pipes has actually been producing square and rectangular items for over forty years. Our experience with these products has resulted in the creation of our round and pipe size line. Abter Steel pipes can now supply your pipe piling needs with the exact same excellence.

Abter Steel Pipes is now manufacturing ERW Pipe Stacking to ASTM A252 in Grades 1, 2, and 3. Pipe Piling is produced from 6.625″ O.D. to 16″ O.D. in walls from.188″ to.688″ as much as 78 feet long.

The most popular reactor tube sizes are 10.75 “OD and 12.75” OD.

When it concerns the adaptability of developing with tube and pipe items, designers, designers, and engineers specify Self-reliance Tube.

This requirements covers small density of the wall steel pipe stacks of round shape and uses to pipe stacks in which the steel cylinder serves as an irreversible load-carrying member, or as a shell to form cast-in-place concrete piles.

The completed pipe piles will be fairly straight and shall not include imperfections in such number or of such character regarding render the pipe unsuitable for pipe piles.

Surface area flaws, the depth of which does not go beyond 25% of the small wall density, will be permitted. These might be explored by grinding or submitting to develop the depth.

Surface flaws, the depth of which goes beyond 25% of the nominal wall thickness will be considered defects. Repair work of problems by welding will be permitted when the depth of defect does not go beyond 33 1/2 % of the small wall density. Before welding the defect will be completely gotten rid of.

ASTM Requirements A252 explains nominal (average) wall steel pipe piles of round shape and applies to pipe piles in which the steel cylinder functions as an irreversible load-carrying member or as a shell to form case-in-place concrete piles.

Surface imperfections surpassing 25% of the small wall in depth are considered problems. Defects not exceeding 22.5% of the small wall in depth may be repaired by welding. Before welding, the defect will be totally eliminated.

MECHANICAL PROPERTIES – TENSILE REQUIREMENTS

| Grade 1 | Grade 2 | Grade 3 | |

| Tensile Strength, min, psi | 50,000 | 60,000 | 66,000 |

| Yield Strength | 30,000 | 35,000 | 45,000 |

CHEMICAL REQUIREMENTS FOR A252

| Phosphorus | |

| Seamless and ERW Welded | Max% 0.050 |

Weight

The weight of any length of stack will not differ more than 15% over or 5% under the nominal density weight. Each length will be weighed independently.

Thickness

The minimum wall thickness at any point shall not be more than 12.5% under the nominal wall thickness specified.

Size

The outside diameter of steel pipe stacks will not differ more than ± 1% from the diameter specified.

Length

Length as specified with a tolerance of ± 1 ².

| Product Name | ASTM A252 Grade 2 Steel Pipe |

| Diameter | 14 inch |

| Wall Thickness | STD |

| Length | Random length from 3m to 18m |

| Pipe Standard | ASTM A252, ASTM A53, A106, API 5L, ASTM A500, etc |

| Steel Grade | GR1, GR2, GR3, S275J0H, S275JRH, S275J2H, S355J0H, S355JRH, |

| Application | Piling tube, industrial pipes, structure steel tube, system pipe, |

| Pipe Coating | Varnish paint, anti rust oil, or other coating required |

| Package | Plastic caps on both ends, Steel bundle etc. |

certifications: Upon request of the buyer, in the agreement or order, a maker’s accreditation that the product was manufactured and checked in accordance with this spec together with a report of the chemical and tensile tests will be provided.