Guide to Butt Welding Steel Pipe Elbows

November 21, 2023

large diameter Square Steel Pipe manufacturing Method – PART 2

November 25, 2023【0001】

[Industrial Application Field] The present invention relates to a continuous hot forming method of large-diameter rectangular steel pipes, and more specifically, to a thick-walled steel strip. The two ends are butt welded by cold plastic processing parallel to its longitudinal direction to form a large-diameter steel pipe with a closed curve in cross-section. After continuous shaping, the steel pipe is heated as a whole and directly sent to the square cross-section forming process for thermal processing to form a steel pipe, which is characterized by a square shape. The cross-sectional shape of the single-slit large-diameter rectangular steel pipe, especially the corner material, involves a hot-forming method of thick-walled square steel to eliminate residual internal stress and improve the toughness of the pipe.

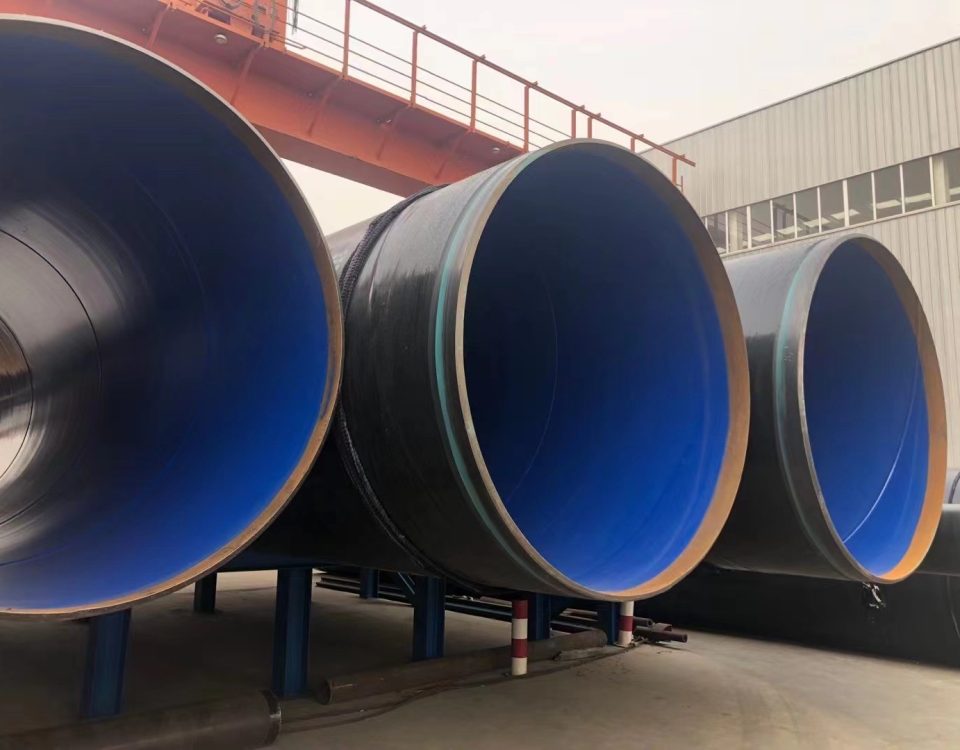

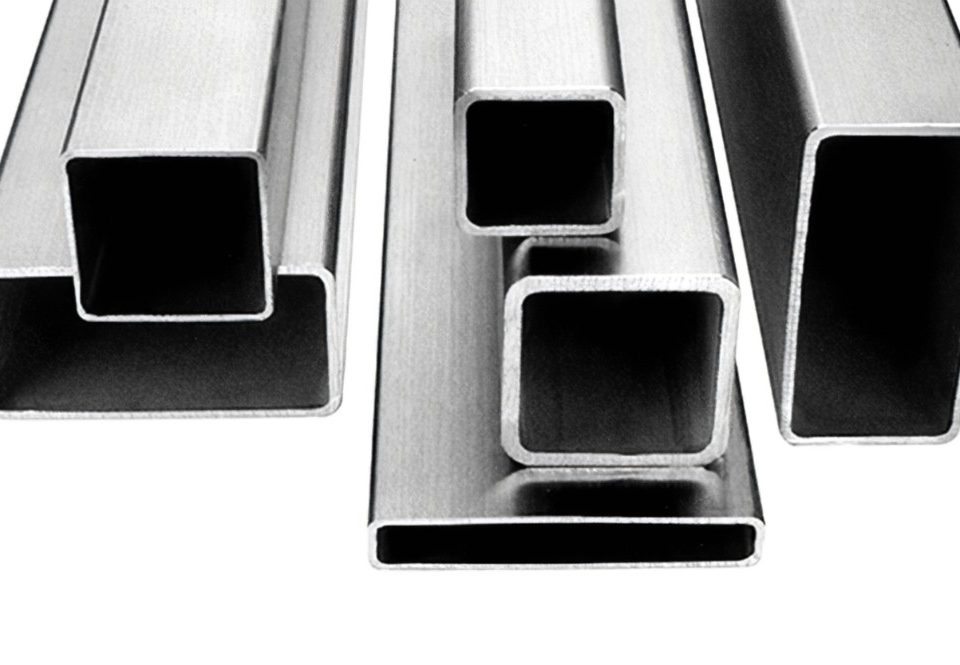

Rectangular Steel Pipe

En10210 10219 S235 S275 S355 S355j2 S355J2H Square Rectangular Steel Pipe

| Item | Details |

| Type | Seamless or welded rectangular steel pipes |

| Standard | JIS G3474,DIN EN 10216-1,DIN EN 10208-1,DIN EN 10217-1,DIN EN 10305,DIN EN 10025,ASTM A53,ASTM A312,ASTM A53M,ASTM A312M,ASTM A513,GB/T 12770-2002,GB/T 3094,GB T14291,GB/T14975 |

| Grade | Q235,Q345,Q195,Q215,10#,20#,45#,Q345B,Q345D,Q460D,S235JRH,S355J2H,S355JRH. |

| Dimensions | 20 x 20 to 600 x 600 square tubes, 20 x 30 and 400 x 800 rectangular tubes; Thickness: 1.5mm to 32mm, |

| Length | 1-12.9m random length,or Fixed length( 5.8m,5.85m,6m.11.8m.12m) |

| Min.Order quantity | We can accept 1 pcs/size if we have stock. |

| Payment term | TT or LC |

| Package | Bundles or loose |

| Delivery time | Depends on the specific orders,normally 45days |

Square tube application fields: widely used in machinery manufacturing, construction industry, metallurgical industry, agricultural vehicles, agricultural greenhouses, automobile industry, railways, highway guardrails, container skeletons, furniture, decoration and steel structure fields, etc.

Used in engineering construction, glass curtain walls, door and window decoration, steel structures, guardrails, machinery manufacturing, automobile manufacturing, home appliance manufacturing, shipbuilding, container manufacturing, electric power, agricultural construction, agricultural greenhouses, bicycle racks, motorcycle racks, shelves, fitness equipment, Leisure and travel products, steel furniture, various specifications of oil casing, oil pipes and pipeline pipes, water, gas, sewage, air, heating and other fluid transportation, fire protection and brackets, construction industry, etc.

Square steel tube hollow section for heavy steel structure|colled formed|hot finished|large size SIZE CHART

|

Thick wall pipe scale table (mm)

|

Thick-walled rectangular pipe scale table (mm)

|

||

|

16×16×0.4~1.5

|

380×380×8.0~30.0

|

10×20×0.6~1.5

|

250×150×6~12.0

|

|

18×18×0.4~1.5

|

400×400×8.0~30.0

|

14×21×0.6~1.5

|

250×100×6~12.0

|

|

20×20×0.4~1.5

|

420×420×10.0~30.0

|

15×30×1.5~1.5

|

250×200×6~30.0

|

|

25×25×0.6~2.0

|

450×450×10.0~30.0

|

15×38×0.6~1.5

|

300×150×6~30.0

|

|

30×30×0.6~4.0

|

480×480×10.0~30.0

|

20×30×0.6~2.0

|

300×200×6~30.0

|

|

34×34×1.0~2.0

|

500×500×10.0~30.0

|

20×40×0.8~2.0

|

300×250×6~30.0

|

|

35×35×1.0~4.0

|

The other specifications are as follows:

|

20×50×1.0~2.0

|

400×250×8~30.0

|

|

38×38×1.0~4.0

|

550×550×10.0~40.0

|

22×35×0.9~2.0

|

400×300×8~30.0

|

|

40×40×1.0~4.5

|

600×600×10.0~40.0

|

25×40×0.9~3.75

|

450×200×8~30.0

|

|

44×44×1.0~4.5

|

700×700×10.0~40.0

|

25×65×1.0~2.0

|

450×250×8~30.0

|

|

45×45×1.0~5.0

|

800×800×10.0~50.0

|

30×40×1.0~3.75

|

400×300×8~30.0

|

|

50×50×1.0~5.0

|

900×900×10.0~50.0

|

30×45×1.0~3.75

|

400×350×8~30.0

|

|

60×60×1.5~5.0

|

1000×1000×10.0~50.0

|

30×50×1.0~4.0

|

500×200×10~30.0

|

|

70×70×2.0~6.0

|

30×60×1.0~4.5

|

500×250×10~30.0

|

|

|

75×75×2.0~6.0

|

40×50×1.0~4.5

|

500×300×10~30.0

|

|

|

80×80×2.0~6.0

|

40×60×1.0~5.0

|

500×350×10~30.0

|

|

|

85×85×2.0~6.0

|

40×80×1.5~5.0

|

500×400×10~30.0

|

|

|

95×95×2.0~8.0

|

40×100×2.0~5.0

|

500×450×10~30.0

|

|

|

100×100×2.0~8.0

|

50×60×2.0~5.0

|

The other specifications are as follows:

|

|

|

120×120×4.0~8.0

|

50×80×2.0~5.0

|

600×200×10~28.0

|

|

|

150×150×6.0~10.0

|

50×100×2.0~8.0

|

600×400×10~28.0

|

|

|

180×180×6.0~12.0

|

60×80×2.0~6.0

|

600×500×10~28.0

|

|

|

200×200×6.0~30.0

|

80×100×2.0~8.0

|

800×400×10~28.0

|

|

|

220×220×6.0~30.0

|

120×60×2.5~10.0

|

800×600×10~28.0

|

|

|

250×250×6.0~30.0

|

120×80×2.5~10.0

|

800×700×10~28.0

|

|

|

280×280×6.0~30.0

|

150×100×2.5~12.0

|

1000×400×10~28.0

|

|

|

300×300×8.0~30.0

|

180×150×2.5~12.0

|

1000×500×10~28.0

|

|

|

320×320×8.0~30.0

|

200×100×4~12.0

|

1000×600×10~28.0

|

|

|

350×350×8.0~30.0

|

200×150×4~12.0

|

1000×800×10~28

|

|

【0002】

[Existing Technology] Columns in steel structures are in high demand.

Traditionally, the mass production method of cold processing of thick-walled and large-diameter rectangular steel pipes< /span>

The following construction methods were adopted. The hot-rolled coil passes through a leveler to form a flat steel strip, and both sides of the coil are subjected to fixed width and bevel processing. The strip steel is conveyed in series through the processing stages of segmentation, clustering, fin rolling, etc. During this process, the strip steel is formed sequentially. After the right-angle section is formed into a nearly circular shape, a circular steel pipe is constructed using high-frequency resistance and induction. Welding device and squeeze roller. That’s it. After the round steel pipe is cooled, it passes through a sizing machine, a nursing table, a Turk head, etc., and then is shaped into an angular section to produce a square diameter steel pipe.

[0003] In the above method, a thick steel plate with a flat or curved surface is cold plastic processed to form a rectangular steel pipe. =2>Therefore, the process of bending approximately 90 degrees is included. However, when the thick steel plate is cold-bent at about 90 degrees, the cross-section of the steel plate at the bend and the neutral plane deform <a i=5> as the boundary, the tensile force acts on the outer material, and the compressive force acts on the inner material. Therefore, even if the necessary R is applied to the part, the plastic deformation will exceed the elastic limit of the material, and it cannot be said that the possibility of the mechanical properties of the deformed part, especially the corner piece, deteriorating and brittle fracture does not exist.

0004] Steel structures, buildings, etc. that use this type of large-diameter rectangular steel pipes as columns are generally constructed after completion. 2> Not only can it support its own weight and the attached weight structure without deformation for a long time, but it can also withstand the stress caused by external forces such as earthquakes and typhoons. These columns are required to be able to safely withstand repeated loads and in principle cannot be replaced or repaired. Often constructed. In recent years, this kind of cold-formed large-diameter rectangular steel pipe has been frequently used as columns in building structures, and since it is also used as a column in high-rise buildings, in view of the above situation, in this case, the steel pipe Material deterioration based on cold working during the molding process has been recognized as a problem. Recently, experts believe that this type of large-diameter rectangular steel pipe produced by cold molding accounts for the majority of applications in steel structures, and some people seem to be worried about whether it is suitable as the main structural material of buildings. object.

0005 In order to solve the material problems existing in cold-formed large-diameter rectangular steel pipes, the traditional In point, A< /span>. There is a way to heat to the transition point 3 phase change 1. It is then passed through a multi-stage rolling mill and shaped into a rectangular cross-section. When the above method is used, the product quality is better, but due to the deformation of both ends of the steel pipe, the yield is poor, each piece is processed once, and the output is low. Additionally, annealing is expensive because the entire steel pipe is heated to high temperatures. The formed large-diameter rectangular steel pipe is placed into an annealing furnace and the entire part is heated until the residual stress in the material is almost completely eliminated and annealed. There are two methods for this situation: heating the steel into A. Using fossil fuels such as oil, natural gas or electricity, ready-made ERW steel pipes, seamless pipes, etc. are all heated.

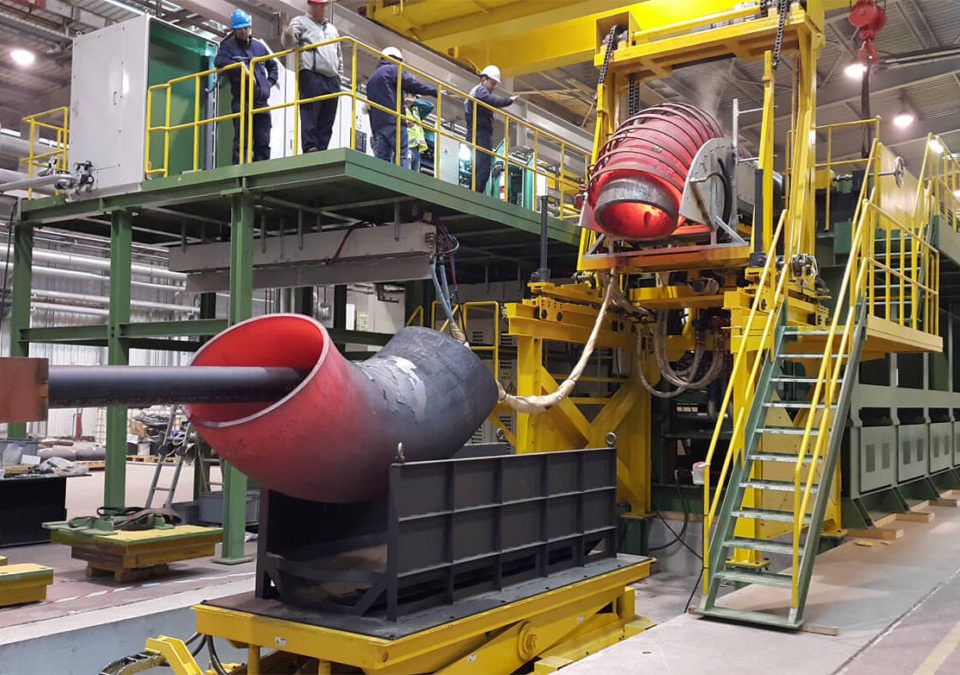

0006]The hot-rolled coil passes through the straightening machine and undergoes various

Forming roller frames and high frequency welding equipment followed by cold forming

Formed into a circular steel tube. After forming, the steel pipe is heated online using electricity (induction), fossil fuels such as gas or petroleum. Parts of the steel pipe are formed into angular crosses through intermediate rollers, then cooled and made into products. The above method uses online heating, so if it goes well, the yield will be better and the productivity will be higher than the above situation, but once the production line fails or stops due to welding defects, the productivity and yield will drop. will be significantly reduced.

0007] In addition, when installing an in-line heating furnace that uses fossil fuels such as gas and oil, it is necessary =2> Because the welding speed is fast (a certain welding speed is required to obtain a good welded joint through high-frequency welding), in steel pipe materials The residual stress of the steel is completely eliminated. In addition, when using fossil fuels such as gas and oil to heat circular steel pipes, the heat source cannot enter the inside of the steel pipe, so it is difficult for the material to heat the steel pipe uniformly, and there are temperature control problems. Steel pipes, resulting in uniform product quality, may not be. , causing the production line to be too long and limiting the location. a i=9> There is difficulty in selection or the amount of venture capital investment will be higher than expected. Space A needs to install a heating furnace with a length of 0m to 300m.

0008] In addition, fossil fuel heating furnaces generally have extremely low thermal efficiency, and pollution control measures based on exhaust gas and waste heat may sometimes need to be taken into account. In addition, the maintenance and management of fossil fuel combustion equipment and heating furnaces also require manpower. But its advantages are low fuel costs, relatively easy transportation, easy availability and acceptance regardless of location conditions. On the other hand, heating devices that use electric energy require less space for heating, and require uniform heating and thorough heating temperature control. However, the electricity cost is high, and it is difficult to obtain the required large-capacity power depending on the usage. Site conditions. >. In other words, there are situations where transmission facilities are not available. It is understood that the following technical problems currently exist: [0009]

[Problems to be solved by the invention] The purpose of the construction method of the present invention is to solve the following problems: The purpose of the present invention is to develop a new thermoforming method that can eliminate the problems inherent in the above method as much as possible. to less than the allowable residual stress, and make the entire material uniform to improve the toughness of the flat plate section. Shaped steel pipe to eliminate internal stress at the corners

【0010】

[Means for Solving the Problem] In order to achieve the above object, the construction method of the present invention has the following structural elements: At the same time, a high-frequency heating device or a fossil fuel burner is used to locally heat only the vicinity of the planned corner. The steel pipe is a large steel pipe. Thermal forming method of diameter rectangular steel pipes, characterized by transferring them to rollers to represent square shaped steel pipes. , or combined heating of the above two heating methods. (1) The entire outer circumference of a continuous circular steel pipe is formed by forming a strip steel plate into a circle with a cross-section perpendicular to the length direction, and butt-welding both sides of the strip steel plate. 4> The round steel pipe is formed by heating the billet using a combination of heating using natural gas, petroleum and other fossil fuels as heat sources and high-frequency heating using electric energy. The steel pipe is transferred to the rolling mill for corner forming, and the temperature is controlled at the same time. Maintain the desired temperature uniformity throughout the tube. Hot forming method for large diameter square steel tubes. (2) The entire outer circumference of a continuous circular steel pipe formed by forming a strip steel plate into a circular shape with a cross-section perpendicular to the length direction and butt welding both sides of the strip steel plate. 10> High-frequency heating devices using fossil fuel heat sources such as gas, oil, or electric energy

【0011】

[Operation] (1) In view of the above current situation, the construction method of the present invention

Adopt steel pipe composite heating method, that is, steel pipe rising method

Heating, most heating using only fossil fuels,

Finally, heating uses electricity, which requires precise equipment temperature control.

For the initial heating of steel pipes that require a large amount of heat, it is easier to obtain a large amount of heat by using high-frequency heating methods. >Use simple, low-cost fossil fuels and strict temperature control. For final heating, the power is easy to adjust, but expensive to reduce the overall cost of steel pipe annealing and to be able to correctly adjust the final heating temperature of the steel pipe anyway. 0012] In addition to (2), in the combustion heating of fossil fuels, as mentioned above, in order to heat the steel pipe to the required temperature, a long heating furnace equipment is required, which may cause difficult conditions in selecting the location of the production line, However, if a high-frequency heating device is installed in the front stage as a heating method, the high-frequency heating device will always use normal-temperature round steel pipes. /span> Another advantage is that it can extend the service life. As well as the maintenance, management and life of the equipment, there is no need to pay more attention than usual to the heat resistance and heat dissipation methods of the equipment.

(3) Regarding the overall or partial heating of the above-mentioned round steel pipe

, so that the residual internal stress in the steel can be resolved or removed

A1 Method of heating steel pipe to phase transformation point, A

Changing a>, the temperature cannot be controlled to uniform heating and uniform heating. The final heating device of the steel pipe can use electric heating. The above advantages are naturally provided by the heating device and can reduce the residual internal stress in the round steel pipe material formed by bending and welding the strip steel. After the welding deformation is eliminated, the round steel pipe is transferred to the square forming roller frame, and the round steel pipe is heated by the forming roller, and gradually formed into a rectangular cross-section through mechanical processing. Circular steel pipes have large diameters, thick steel plates, and large heat capacities, so the steel pipes must go through the square rolling process to form regular shapes. Even after the rectangular steel pipes are formed, they are still in a high temperature state. Phase change point 1. Even if the final heating temperature is close to the steel A Consider the method of heating to the phase transformation point 30014] The advantages of combined heating are limited to the above-mentioned case where a high-frequency heating device is installed at the last stage of the heating device. Of course, even if the high-frequency heating device is installed on the front stage side, it can Obtain the same results. When the round steel pipe is heated to near the A3 transformation point, deterioration occurs due to cold plastic processing. > a> Point heating. Transformation 1 means that the selection of the above A position conditions, etc. is relatively easy. Gaining advantages such as also preventing the device from becoming too long. Regardless of energy availability, yes, heating equipment inevitably becomes larger. , heating costs also increase. According to the construction method of the present invention, the lack of available electric heating capacity can be compensated by heating devices using fossil fuels. Planning can promote the recrystallization of the steel crystal structure and reduce the residual stress inside the steel, but conventional methods cannot =9> have the shortcomings mentioned above. Then, compared with the above situation, heating the steel to a temperature higher than the phase transformation point, in order to heat to a i=13>

0015] However, the residual internal stress and work hardening of the large-diameter rectangular steel pipe formed by this method, especially near the weld and at the corners, can be almost eliminated. Completely removed, high-precision rectangular steel pipes can be produced by hot forming, thereby providing homogeneous, high-grade large-diameter rectangular steel pipes. In short, since the formation process of the corners of the steel pipe section is carried out through thermal processing, the formation of the corners is easy, and the four corners of the outer wall of the steel pipe can be easily formed. The corners of the steel pipe caused by bending about 90 degrees, the residual stress and residual strain caused by the butt welding of the steel have been removed to the extent that there are no practical problems, and there is no risk of residual stress in the formed steel pipe material. Alternatively, the deterioration of the material at the corners is almost completely restored. 0016] The existing method of forming a single-slit round steel pipe into a rectangular steel pipe

Medium, when forming round steel pipe

A long space is provided before the square tube forming and rolling process for natural cooling at the heating temperature of the high-frequency welded steel. However, the method of the present invention can utilize the above-mentioned space to install a steel pipe heating device. The construction method is extremely long compared to traditional installations and does not require a lot of space. Therefore, according to the construction method of the present invention, it is possible to solve the steel pipe corners based on the plastic deformation of the corners of large-diameter rectangular steel pipes that have been considered a problem recently. >. Moreover, compared with the traditional construction method equipped with an annealing furnace using fossil fuels as a heat source, the method of the present invention has high productivity, and even if the steel pipe material is actually annealed, the cost increase is small. In addition, compared with the heating furnace used in the existing in-line method, the equipment space is smaller, and the heating temperature can be easily controlled to uniformly heat the steel material. With good quality and high forming accuracy, it can produce uniform large-diameter rectangular steel pipes. Defects due in part to material degradation can be eliminated to the point where they are no longer a real problem

0017] (4) The material defects that are considered problematic in large-diameter rectangular steel pipes on the market are caused by problems in the steel pipe forming process. > Local materials of structural materials due to deterioration, such as steel pipe corner materials hardened by cold bending and residual stress, etc. It’s a weakening. Therefore, in the second invention method, just before sending the single-slit round steel pipe to the square forming roller for processing, at least the steel near the predetermined corner of the outer circumferential surface of the steel pipe is heated to the A transformation point, a situation similar to the above can be obtained ( 3), I look forward to playing with it. However, in order to form a circular steel pipe into a rectangular cross-section, only the area near the predetermined corner is heated, which will not cause the steel pipe peripheral wall material to deteriorate and the stiffness to be uneven, even if it passes through the forming roller. Therefore, large-diameter rectangular steel pipes cannot be formed with high precision. 30018] To this end, the planned corners of the steel pipe peripheral wall are heated, and the entire steel pipe is heated in advance. Since it is essentially equivalent to phase change point heating, it will reduce the cost of thermal annealing of steel pipe products. 1. The heating equipment and the heat required for heating are also A, which is basically equivalent to phase change point heating. 1. The heating device itself is A. Although the effect is close to phase change point heating, the steel pipe 3. A, thereby smoothing the uneven material stiffness of the steel pipe’s peripheral wall. In addition, we eliminate the welding strain generated near the steel pipe weld, eliminate the hardening of the steel when the round steel pipe is formed, hot-form the steel, and shape the round steel pipe cross-section. According to the second inventive method, the mass of the large-diameter rectangular steel pipe is about that of the entire steel pipe when heated to a state close to deformation [0019] For the overall heating of the round steel pipe, use (3)- or the method described above

2> It is also possible, and if the heating plan is to heat the entire steel pipe, that is, to locally heat the corners of the steel pipe, the steel can be preheated. Since the subsequent heating is local heating, the heating energy is relatively small. In addition, there are local heating devices for round steel pipes using fossil fuels as heat sources and devices using high-frequency heating devices. It is known that it is easier to control the temperature of the steel and the heat distribution within the steel by heating.

【0020】

[Examples] The following are examples of a large-diameter rectangular steel pipe production line equipped with equipment for implementing the method of the present invention and the above-described method. >According to this application, the embodiment will be described according to the accompanying drawings, but the specific structural parts that constitute each section of the right steel pipe production line

0021 [0021] (Part 1) Figure 1 shows a production line of an embodiment of a thermoforming equipment for large diameter rectangular steel pipes implementing the construction method of the present invention. Is a schematic block diagram. In the figure, along the straight line along the material conveying direction, 1 is the coil installation mechanism, 2 is the leveler, 3 is the steel plate width determination and groove section; 4 is the steel plate decomposition roller level; 5 is the multi-stage steel plate section rounding roller mechanism; 6 It is a finishing roller table, 7 is a high-frequency resistance welding device, 8 is a mechanism for removing the inside or outside of the weld bead, 9 is fossil fuel, 10 is a high-frequency heating furnace; 11 is a multi-stage rectangular section forming roller mechanism; 12 is formed steel pipe cooling device; a> and cooling section; 13 is the steel pipe length measuring mechanism; 14 is the straightening part; 15 is the knife; 16 is the straightening device; 7 is the steel pipe sizing and cutting machine. However, there are many devices not shown in the figures, such as roll unwinding mechanisms, pinch rollers, emergency cutters, inspection devices, etc.