ASME B16.9 Seamless stainless steel bend | Seamless steel BW elbow

December 6, 2023

Nickel Alloy steel pipe – Hastelloy C-2000 UNS N06200

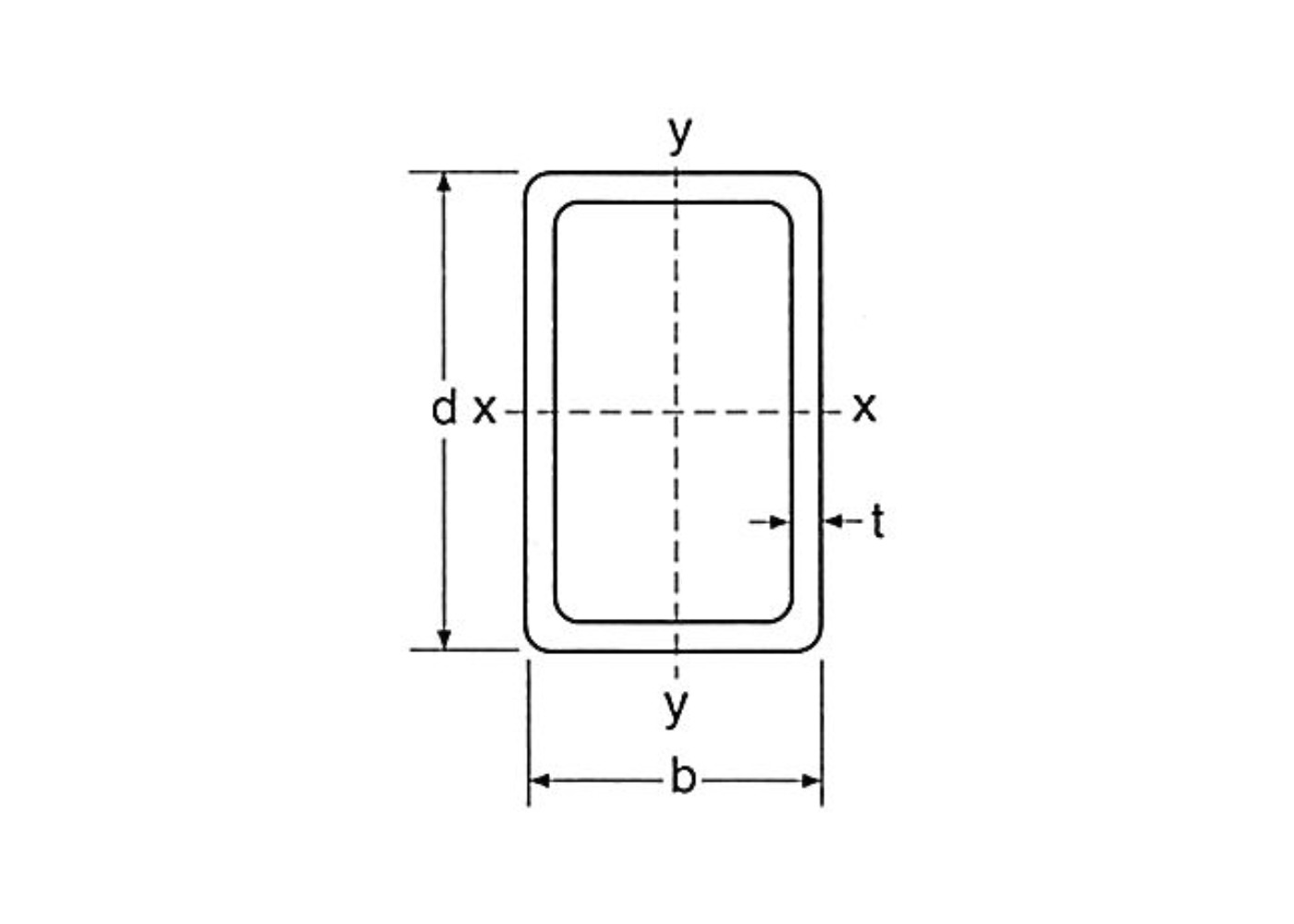

December 10, 2023Dimensions and properties to BS EN 10210: 2006

abtersteel stock Hot Finished Rectangular Hollow Sections in the UK sizes listed below. We also offer a full steel processing service for all materials, including cutting and drilling.

EN10210 Hollow Section for Structural | Square & Rectangular Steel Pipe

EN10210 is a standard used to specify the technical delivery conditions for hot finished hollow sections of circular, square, rectangular, or elliptical forms of structural steel. These steel sections have various applications, including the construction of buildings, bridges, and other structural components.

Key Features of EN10210 Hollow Sections

- Dimensions: These hollow sections can come in various sizes and thicknesses, depending on the application, typically ranging from 10x10mm to 800x800mm for square sections and 10x20mm to 1000x800mm for rectangular sections.

- Material: The material grades commonly used are S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, and S355K2H. Each grade has different mechanical properties that make them suitable for specific applications.

- Manufacture: The sections are made via hot forming, followed by heat treatment processes such as normalizing or normalizing rolling.

- Appearance: The section shape can be circular, square, rectangular, or elliptical, with a smooth surface.

Applications

EN10210 hollow sections are commonly used in various structural applications, including:

- Buildings: They are used in the construction of buildings, providing support and stability.

- Bridges: The sections are used in the construction of bridges, where high strength and durability are required.

- Machinery: They are also used in the manufacture of machinery where rigid structures are necessary.

- Infrastructure: Other applications include the construction of infrastructure such as airports, stadiums, and railways.

Advantages

Using EN10210 hollow sections in structural applications offers several benefits:

- Strength: The hollow sections offer high strength-to-weight ratio, making them suitable for load-bearing structures.

- Versatility: The square and rectangular sections offer high versatility in terms of design, as they can be easily cut, welded, and formed into various shapes.

- Durability: They are highly durable and resistant to corrosion, which makes them suitable for use in harsh environments.

- Efficiency: The hollow sections can be more efficient than solid sections in certain applications, as they can provide the same structural support while using less material.

Conclusion

EN10210 hollow sections are an important component in the construction and manufacturing industries, providing a strong, versatile, and durable option for structural applications. The standard ensures that these sections meet rigorous quality and safety standards, making them a reliable choice for engineers and architects.

Note: Always consult with a structural engineer or a professional when choosing materials for a specific application to ensure safety and compliance with local regulations and standards.

EN 10210 S355J0H Hot Finish Rectangular Hollow Section Chemical Composition

| Steel Grade | % by mass maximum | |||||||

| Steel Name | Steel Number | C specified thickness (mm) | Si | Mn | P | S | N | |

| <_40 | > 40 <_ 120 | |||||||

| S355J0H | 1.0547 | 0.22 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 0.009 |

EN 10210 Hot Finish S355J0H Structural Rectangular Hollow Section Mechanical Properties

| Steel Grade | Minimum yield strength eH Mpa | Minimum tensile strength Rm Mpa | ||||||||

| Steel Name | Steel Number | Specified thickness in mm | Specified thickness in mm | |||||||

| <_16 | >16 <_40 | >40 <_63 | >63 <_ 80 | >80 <_100 | >100 <_120 | <_3 | >3 <_100 | >100 <_ 120 | ||

| S355J0H | 1.0547 | 355 | 345 | 335 | 325 | 315 | 295 | 510-680 | 470-630 | 450-600 |