ASTM A334 Alloy Steel pipe

December 3, 2023

EN10210 Hollow Section for Structural | Square rectangular steel pipe

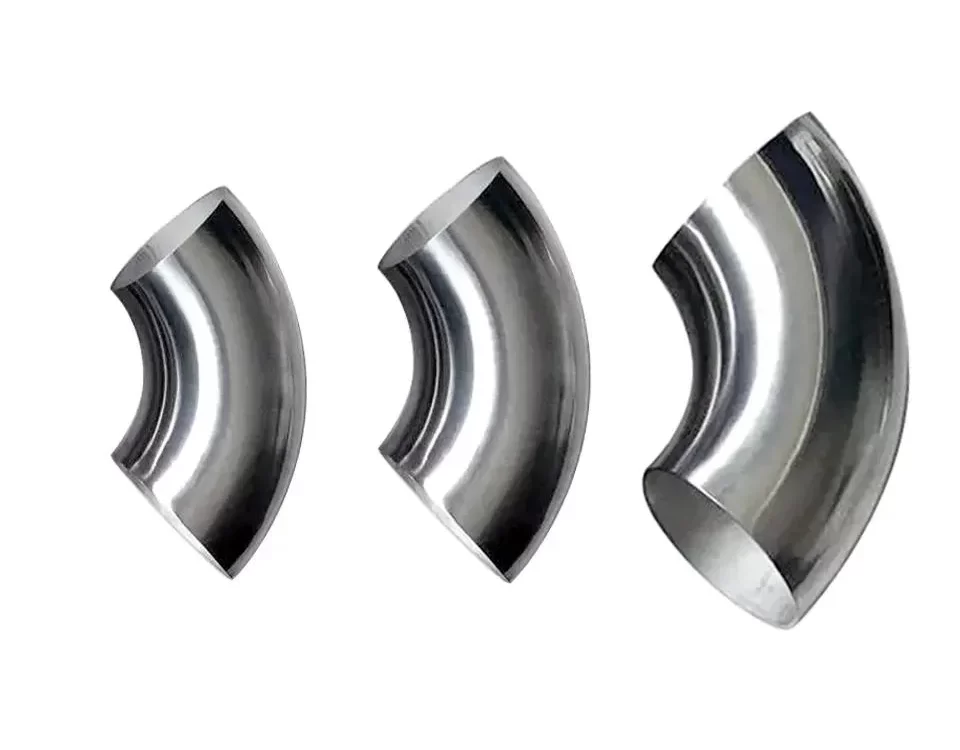

December 7, 2023Seamless stainless bend ASME B16.9 90° SR. Here’s a summary of the key points you’ve mentioned:

- The Seamless stainless bend ASME B16.9 90° Short Radius (SR) Elbow is a specific kind of piping component that is used to change the direction of flow in a piping system.

- This type of elbow is typically installed where space is limited, making it ideal for compact areas.

- For Short Radius (SR) elbows, the center to face distance is equivalent to the nominal pipe size. For instance, if the pipe size is 4 inches, the center to face distance will be 101.6 mm (4 * 25.4).

- The dimensions, tolerances and other specifications for these types of elbows are defined by the ASME B16.9 and ASME B16.28 standards.

- Short radius elbows are only available for 90 and 180-degree bends, not for 45 degrees. On the other hand, long radius elbows are available for all degrees.

- SR elbows are widely used to connect hoses to valves, water pumps, and deck drains. Their compact size and sharp curve make them suitable for these applications.

- The quality of a Seamless stainless bend ASME B16.9 90° SR is strongly linked to the quality of its bending procedures. The strength of the product is also crucial, particularly at the bending point, which is typically the most fragile part.

In general, it’s important to ensure that any piping components used meet the relevant standards and are suitable for their intended application. This includes considering factors such as the material, size, bend radius, and pressure rating.

317/L ; 304/L;316/L;310/S;309/S;347/H;321/321/H;904/L

Applications:

Dairy, food, beer, beverage, pharmacy, cosmetic, etc

Size:

seamless 1/2”~24” (DN15-DN600)

welded 1/2”~48” (DN15~DN1200)

| DN | NPS | OD | Center to End | Center to Center |

| 15 | 1/2 | 18

21.3 |

38 | 76 |

| 20 | 3/4 | 25

26.7 |

38 | 76 |

| 25 | 1 | 32

33.4 |

38 | 76 |

| 32 | 1 1/4 | 38

42.2 |

48 | 96 |

| 40 | 1 | 45

48.3 |

57 | 114 |

| 50 | 2 | 57

60.3 |

76 | 152 |

| 65 | 2 1/2 | 76

73 |

95 | 190 |

| 80 | 3 | 89 | 114 | 228 |

| 90 | 3 1/2 | 101.6 | 133 | 266 |

| 100 | 4 | 108

114 |

152 | 304 |

| 125 | 5 | 133

141.3 139.7 |

190 | 380 |

| 150 | 6 | 168.3

159 165 |

229 | 458 |

| 200 | 8 | 219

216 |

305 | 610 |

Standard: ASME B16.9 ; DIN2605 ; JIS

Thickness: SCH5S-SCH160

Related posts

Induction bends come in standard bend angles (e.g. 45°, 90°, etc.) or can be custom made to specific bend angles. Compound bends (out-of-plane) bends in a single joint of pipe can also be produced. The bend radius is specified as a function of the diameter. For example, common bend radii for induction bends are 3D, 5D and 7D, where D is the nominal pipe diameter.

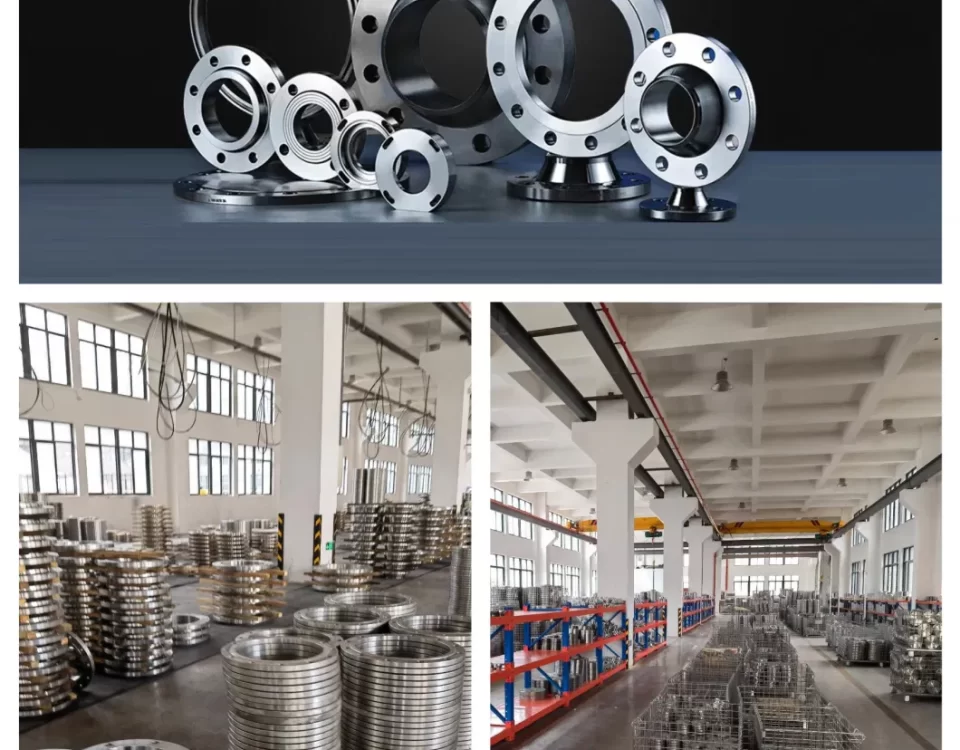

Duplex 2205 and Super Duplex 2507 stainless steel flanges are characterized by their high yield strength, which is twice that of the annealed yield strength of typical austenitic stainless steels, like 304 and 316 stainless steel flanges. Because of this, Duplex 2205 and Super Duplex 2507 steel are some of the most common grades of duplex used for flanges with Super Duplex 2507 flanges being the more corrosion resistant grade of the two.