UNS S31603 316L Stainless Steel Pipe Equivalent Grades and Detailed Specifications

February 20, 2024

Monel K500 N05500 Alloy Steel Pipes & Fittings

February 26, 2024MSS SP-75 WPHY Butt Weld Pipe Fittings –

52, 60, 65, 70

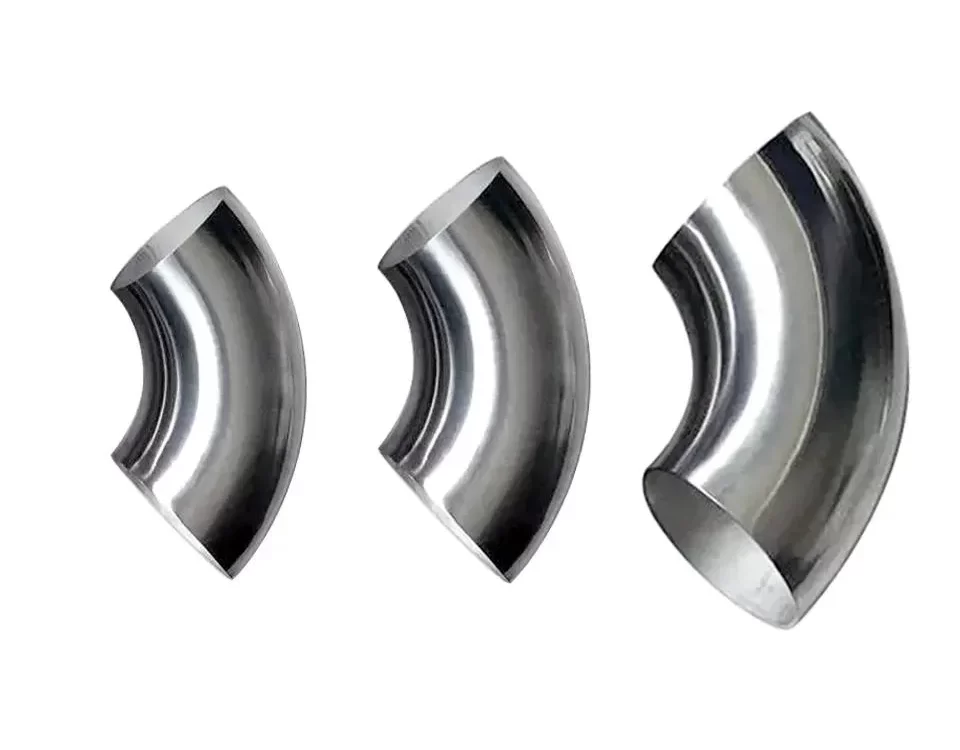

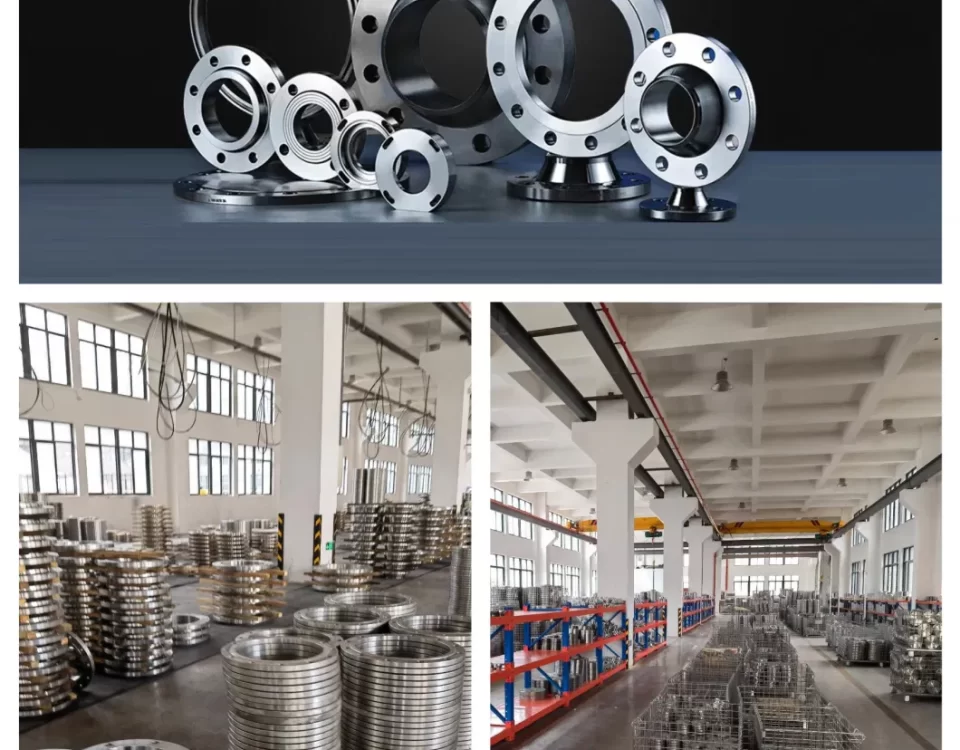

MSS SP-75 WPHY 52, 60, 65, 70 butt weld pipe fittings are essential components used in various industries, particularly in piping systems. These fittings provide a reliable and secure connection between pipes, ensuring efficient and leak-free fluid flow. In this article, we will explore the features, applications, and benefits of MSS SP-75 WPHY 52, 60, 65, 70 butt weld pipe fittings.

I. Features of MSS SP-75 WPHY 52, 60, 65, 70 Butt Weld Pipe Fittings

- High-Quality Materials: MSS SP-75 WPHY 52, 60, 65, 70 butt weld pipe fittings are manufactured using high-quality materials, such as carbon steel or alloy steel. These materials offer excellent strength, durability, and resistance to corrosion.

- Butt Weld Connection: These fittings feature a butt weld connection, which ensures a strong and permanent joint between pipes. The butt weld connection eliminates the need for additional fasteners, providing a streamlined and efficient piping system.

- Wide Range of Sizes and Dimensions: MSS SP-75 WPHY 52, 60, 65, 70 butt weld pipe fittings are available in a wide range of sizes and dimensions, allowing for compatibility with various pipe sizes and configurations. This versatility makes them suitable for diverse applications.

- Conformance to Standards: These fittings comply with the MSS SP-75 standard, which ensures their quality, performance, and dimensional accuracy. The adherence to standards guarantees that the fittings meet industry requirements and can be safely used in different applications.

- Corrosion Resistance: MSS SP-75 WPHY 52, 60, 65, 70 butt weld pipe fittings are designed to withstand corrosive environments. The materials used in their construction, combined with appropriate surface treatments, enhance their resistance to corrosion, extending their service life.

II. Applications of MSS SP-75 WPHY 52, 60, 65, 70 Butt Weld Pipe Fittings

MSS SP-75 WPHY 52, 60, 65, 70 butt weld pipe fittings find extensive use in various industries and applications, including:

- Oil and Gas Industry: These fittings are commonly used in oil and gas pipelines, where they ensure the secure connection of pipes and facilitate the efficient transport of oil, gas, and other fluids.

- Chemical Industry: MSS SP-75 WPHY 52, 60, 65, 70 butt weld pipe fittings are suitable for chemical processing plants, where they provide reliable connections for the safe transportation of corrosive chemicals.

- Power Generation: These fittings are utilized in power plants for connecting pipes in steam, water, and gas systems. They play a crucial role in maintaining the integrity and efficiency of power generation processes.

- Water Treatment: MSS SP-75 WPHY 52, 60, 65, 70 butt weld pipe fittings are used in water treatment facilities, ensuring the smooth flow of water and other fluids in filtration, purification, and distribution systems.

- Construction and Infrastructure: These fittings are employed in construction projects, including commercial buildings, residential complexes, and infrastructure development. They enable the efficient plumbing and fluid management within these structures.

III. Benefits of MSS SP-75 WPHY 52, 60, 65, 70 Butt Weld Pipe Fittings

- Reliable and Leak-Free Connections: The butt weld connection provided by these fittings ensures a reliable and leak-free joint between pipes. This eliminates the risk of fluid leakage, enhancing the overall efficiency and safety of the piping system.

- Durable and Long-Lasting: MSS SP-75 WPHY 52, 60, 65, 70 butt weld pipe fittings are constructed from high-quality materials, making them durable and capable of withstanding harsh operating conditions. Their longevity reduces the need for frequent replacements, resulting in cost savings.

- Versatility and Compatibility: With a wide range of sizes and dimensions available, these fittings offer versatility and compatibility with various pipe configurations. This allows for easy integration into existing piping systems or the creation of new systems to meet specific requirements.

- Ease of Installation: The butt weld connection of these fittings simplifies the installation process, reducing labor and time requirements. This makes them a preferred choice for projects that require efficient and timely completion.

- Cost-Effective Solution: MSS SP-75 WPHY 52, 60, 65, 70 butt weld pipe fittings provide a cost-effective solution for piping systems. Their durability, reliability, and compatibility contribute to long-term cost savings by minimizing maintenance and replacement expenses.

IV. Conclusion

MSS SP-75 WPHY 52, 60, 65, 70 butt weld pipe fittings are essential components in various industries, offering reliable and secure connections for piping systems. With their high-quality materials, butt weld connection, wide range of sizes, and corrosion resistance, these fittings provide numerous benefits in terms of reliability, durability, versatility, and cost-effectiveness.

Whether used in the oil and gas industry, chemical plants, power generation facilities, water treatment plants, or construction projects, MSS SP-75 WPHY 52, 60, 65, 70 butt weld pipe fittings ensure the efficient and leak-free flow of fluids. Their adherence to standards and compliance with industry requirements make them a trusted choice for professionals in need of robust and long-lasting pipe connections.

When selecting MSS SP-75 WPHY 52, 60, 65, 70 butt weld pipe fittings, it is important to consider the specific requirements of the application and consult with industry experts to ensure optimal performance and compatibility. By choosing the right fittings, you can ensure the integrity and efficiency of your piping system, contributing to the success of your projects.

MSS SP-75 WPHY 52, 60, 65, 70 Butt Weld Pipe Fittings Mechanical Strength and Chemical Composition

MSS SP-75 is a specification developed by the Manufacturers Standardization Society of the Valve and Fittings Industry (MSS) that covers high-strength, butt weld pipe fittings used in various industries. The WPHY (Weldable Pipe High Yield) series within the MSS SP-75 specification includes grades WPHY 52, WPHY 60, WPHY 65, and WPHY 70. These grades are designed to provide excellent mechanical strength and are commonly used in applications where high pressure and high-temperature conditions are present. In this article, we will discuss the mechanical strength and chemical composition of MSS SP-75 WPHY 52, 60, 65, and 70 butt weld pipe fittings.

Mechanical Strength of MSS SP-75 WPHY Butt Weld Pipe Fittings

The mechanical strength of MSS SP-75 WPHY butt weld pipe fittings is an essential consideration for their performance in demanding applications. The WPHY grades indicate the minimum yield strength in ksi (kilo-pounds per square inch) of the fittings. Let’s explore the mechanical strength of each grade:

- WPHY 52: The minimum yield strength of WPHY 52 fittings is 52 ksi, indicating their ability to withstand a minimum stress of 52,000 psi without permanent deformation.

- WPHY 60: WPHY 60 fittings have a minimum yield strength of 60 ksi, providing higher strength compared to WPHY 52 fittings.

- WPHY 65: WPHY 65 fittings offer a minimum yield strength of 65 ksi, making them even stronger and suitable for more demanding applications.

- WPHY 70: Among the WPHY grades, WPHY 70 fittings have the highest minimum yield strength of 70 ksi, ensuring exceptional strength and durability.

It’s important to note that the mechanical strength of MSS SP-75 WPHY fittings is not limited to yield strength alone. Other mechanical properties, such as tensile strength, elongation, and impact resistance, also contribute to the overall performance of the fittings. These properties may vary depending on the specific manufacturing process and heat treatment applied to the fittings.

Chemical Composition of MSS SP-75 WPHY Butt Weld Pipe Fittings

The chemical composition of MSS SP-75 WPHY butt weld pipe fittings directly influences their mechanical properties and suitability for different environments. While the exact composition may vary slightly between manufacturers, the following elements are typically present in WPHY fittings:

- Carbon (C): Carbon is a primary element in WPHY fittings and contributes to their strength and hardness. The carbon content in WPHY fittings generally ranges from 0.20% to 0.30%.

- Manganese (Mn): Manganese is added to improve the strength and hardenability of the fittings. The manganese content in WPHY fittings typically ranges from 0.60% to 1.35%.

- Phosphorus (P): Phosphorus is a residual element in WPHY fittings and is usually present in small amounts. Its content is typically limited to a maximum of 0.030% to ensure good weldability.

- Sulfur (S): Sulfur is another residual element in WPHY fittings. Its content is generally limited to a maximum of 0.010% to improve machinability.

- Silicon (Si): Silicon is added to enhance the strength and resistance to oxidation of the fittings. The silicon content in WPHY fittings typically ranges from 0.15% to 0.40%.

- Nickel (Ni): Nickel is sometimes added to improve the toughness and corrosion resistance of the fittings. The nickel content in WPHY fittings can range from 0.20% to 0.50%.

- Chromium (Cr): Chromium is added to enhance the corrosion resistance of the fittings. The chromium content in WPHY fittings is typically limited to a maximum of 0.30%.

- Molybdenum (Mo): Molybdenum is occasionally added to improve the strength and corrosion resistance of the fittings. The molybdenum content in WPHY fittings is typically limited to a maximum of 0.15%.

It’s important to consult the manufacturer’s specifications or contact the supplier for the precise chemical composition of the MSS SP-75 WPHY fittings you require, as slight variations may exist.

| Grade | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Silicon (Si) | Nickel (Ni) | Chromium (Cr) | Molybdenum (Mo) |

|---|---|---|---|---|---|---|---|---|

| WPHY 52 | 0.20% – 0.30% | 0.60% – 1.35% | ≤ 0.030% | ≤ 0.010% | 0.15% – 0.40% | – | – | – |

| WPHY 60 | 0.20% – 0.30% | 0.60% – 1.35% | ≤ 0.030% | ≤ 0.010% | 0.15% – 0.40% | – | – | – |

| WPHY 65 | 0.20% – 0.30% | 0.60% – 1.35% | ≤ 0.030% | ≤ 0.010% | 0.15% – 0.40% | – | – | – |

| WPHY 70 | 0.20% – 0.30% | 0.60% – 1.35% | ≤ 0.030% | ≤ 0.010% | 0.15% – 0.40% | – | – | – |

Please note that this table provides a general overview of the chemical composition requirements for each grade of MSS SP-75 WPHY butt weld pipe fittings. The actual composition may vary slightly between manufacturers, so it’s important to consult the specific manufacturer’s specifications for precise information.

FAQ

Q1: What industries commonly use MSS SP-75 WPHY butt weld pipe fittings?

A1: MSS SP-75 WPHY butt weld pipe fittings are commonly used in industries such as oil and gas, petrochemical, power generation, and offshore applications. These fittings are preferred in high-pressure and high-temperature environments.

Q2: What is the difference between WPHY 52, WPHY 60, WPHY 65, and WPHY 70 fittings?

A2: The difference lies in their minimum yield strengths. WPHY 52 has a minimum yield strength of 52 ksi, WPHY 60 has 60 ksi, WPHY 65 has 65 ksi, and WPHY 70 has the highest yield strength of 70 ksi.

Q3: How does the chemical composition of MSS SP-75 WPHY fittings affect their performance?

A3: The chemical composition directly influences the mechanical properties of the fittings, such as strength, hardness, and corrosion resistance. Elements like carbon, manganese, and chromium contribute to these properties.

Q4: Are MSS SP-75 WPHY fittings weldable?

A4: Yes, MSS SP-75 WPHY fittings are designed to be weldable. However, it’s important to follow proper welding procedures and consult the manufacturer’s guidelines for the specific grade and application.

Q5: Where can I find MSS SP-75 WPHY butt weld pipe fittings?

A5: MSS SP-75 WPHY butt weld pipe fittings are available from various manufacturers and suppliers. It’s recommended to reach out to reputable distributors or consult online platforms that specialize in industrial piping products.

Conclusion

MSS SP-75 WPHY 52, 60, 65, and 70 butt weld pipe fittings offer excellent mechanical strength and are designed to withstand high-pressure and high-temperature conditions. The mechanical strength of these fittings is indicated by their respective minimum yield strengths, with WPHY 70 having the highestmechanical strength. Additionally, the chemical composition of WPHY fittings, including elements such as carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, and molybdenum, plays a crucial role in their performance and suitability for different environments.

When selecting MSS SP-75 WPHY butt weld pipe fittings, it’s important to consider the specific requirements of your application and consult the manufacturer or supplier for detailed specifications. By understanding the mechanical strength and chemical composition of these fittings, you can make informed decisions and ensure the optimal performance and reliability of your piping systems.