A106/ASTM A53 GR.B SMLS Pipe

December 15, 2024

UNS N04401 Monel 401 Alloy Steel Tube

December 21, 2024Comprehensive Outline for ASTM A815 SAF250 / UNS S32750 Super Duplex Buttweld Pipe Fitting

| Heading | Subheadings |

|---|---|

| Introduction | – Overview of ASTM A815 SAF250 / UNS S32750 – Importance of buttweld pipe fittings in industries |

| Understanding ASTM Standards | – What is ASTM A815? – Role of ASTM standards in ensuring material quality |

| What is SAF250 / UNS S32750? | – Overview of Super Duplex Stainless Steel – Key features of UNS S32750 material |

| Chemical Composition | – Breakdown of SAF250 / UNS S32750 composition – Comparative analysis with other stainless steels |

| Mechanical Properties | – Tensile strength – Yield strength – Elongation and impact resistance |

| Corrosion Resistance | – Resistance to pitting and crevice corrosion – Stress corrosion cracking resistance |

| Types of Buttweld Pipe Fittings | – Elbows – Tees – Reducers – Caps and stub ends |

| Applications of SAF250 / UNS S32750 | – Oil and gas industries – Chemical processing plants – Marine and offshore structures |

| Advantages of Using Super Duplex Fittings | – Enhanced strength – Cost-effectiveness – Long-term durability |

| Manufacturing Process | – Overview of the buttweld process – Forming, welding, and heat treatment methods |

| Dimensional Standards | – ASME B16.9 – Custom dimensions |

| Testing and Quality Assurance | – Non-destructive testing (NDT) – Hydrostatic and mechanical tests |

| Global Supply and Sourcing | – Key manufacturers and suppliers – Certification requirements |

| Pricing Factors | – Material costs – Manufacturing and testing costs |

| FAQs | – At least six frequently asked questions |

| Conclusion | – Summary of benefits and key applications |

ASTM A815 SAF250 / UNS S32750 Super Duplex Buttweld Pipe Fitting

Introduction

ASTM A815 SAF250 / UNS S32750 super duplex stainless steel is a premium material widely used in critical industries for its exceptional mechanical properties, corrosion resistance, and durability. Buttweld pipe fittings, manufactured using this grade, play a vital role in ensuring efficient and reliable piping systems in applications ranging from oil and gas to chemical processing. This article delves into the technical details, benefits, and applications of SAF250 / UNS S32750 buttweld fittings to provide a comprehensive guide for engineers, buyers, and end-users.

Understanding ASTM Standards

What is ASTM A815?

The ASTM A815 standard defines the requirements for wrought ferritic/austenitic (duplex) stainless steel pipe fittings. It encompasses specifications for chemical composition, mechanical properties, and testing methods to ensure uniformity and reliability.

Role of ASTM Standards in Ensuring Material Quality

ASTM standards provide global benchmarks for quality assurance. For SAF250 / UNS S32750, compliance with ASTM A815 guarantees that the material meets industry demands for strength, corrosion resistance, and durability under harsh conditions.

What is SAF250 / UNS S32750?

Overview of Super Duplex Stainless Steel

Super Duplex stainless steels are known for their dual-phase structure, combining austenitic and ferritic microstructures. UNS S32750 is a leading grade in this category, offering excellent mechanical strength and corrosion resistance.

Key Features of UNS S32750 Material

- High chromium (24-26%) and molybdenum (3-5%) content for superior corrosion resistance.

- Enhanced resistance to chloride-induced stress corrosion cracking.

- Excellent weldability and machinability.

Chemical Composition

The following table details the chemical composition of UNS S32750:

| Element | Percentage |

|---|---|

| Chromium (Cr) | 24.0 – 26.0% |

| Nickel (Ni) | 6.0 – 8.0% |

| Molybdenum (Mo) | 3.0 – 5.0% |

| Nitrogen (N) | 0.24 – 0.32% |

| Carbon (C) | ≤ 0.03% |

| Iron (Fe) | Balance |

Mechanical Properties

Super Duplex UNS S32750 exhibits exceptional mechanical properties:

| Property | Value |

|---|---|

| Tensile Strength | ≥ 800 MPa |

| Yield Strength | ≥ 550 MPa |

| Elongation | ≥ 15% |

| Hardness (HBW) | ≤ 310 |

These properties make UNS S32750 ideal for high-pressure and high-temperature applications.

Corrosion Resistance

Resistance to Pitting and Crevice Corrosion

The high chromium and molybdenum content in SAF250 ensures outstanding resistance to localized corrosion, even in chloride-rich environments.

Stress Corrosion Cracking Resistance

Its duplex structure provides excellent resistance to stress corrosion cracking, making it suitable for marine and offshore industries.

Detailed Table for ASTM A815 SAF250 / UNS S32750 Buttweld Pipe Fittings

Dimensional Standards for Common Fittings

| Fitting Type | Size Range (Inches) | Dimension Standards | Wall Thickness (Schedules) |

|---|---|---|---|

| Elbows (45°/90°) | ½” – 48″ | ASME B16.9 | SCH 10 to SCH XXS |

| Tees | ½” – 48″ | ASME B16.9 | SCH 10 to SCH XXS |

| Reducers | ½” – 48″ | ASME B16.9 | SCH 10 to SCH XXS |

| Caps | ½” – 48″ | ASME B16.9 | SCH 10 to SCH XXS |

| Stub Ends | ½” – 48″ | ASME B16.9 | SCH 10 to SCH XXS |

Comparison of SAF250 / UNS S32750 with Other Grades

| Property | SAF250 / UNS S32750 | 316 Stainless Steel | 2205 Duplex Steel |

|---|---|---|---|

| Tensile Strength (MPa) | ≥ 800 | 515 | 620 |

| Yield Strength (MPa) | ≥ 550 | 205 | 450 |

| Pitting Resistance Equivalent Number (PREN) | > 40 | ~ 26 | ~ 35 |

| Chloride Stress Corrosion Resistance | Excellent | Moderate | Good |

Manufacturing Tolerances for Buttweld Fittings

| Parameter | Tolerance | Standard Reference |

|---|---|---|

| Wall Thickness (t) | ± 12.5% of nominal | ASME B16.9 |

| Diameter (D) | ± 1% or ± 0.5 mm | ASME B16.9 |

| Length (H) | ± 1% or ± 0.5 mm | ASME B16.9 |

Testing Specifications for UNS S32750 Fittings

| Test Type | Purpose | Testing Method |

|---|---|---|

| Non-Destructive Testing | Detect surface/subsurface flaws | Ultrasonic or Radiography |

| Hydrostatic Testing | Verify pressure resistance | Water under pressure |

| Hardness Testing | Ensure material hardness | Brinell or Rockwell Test |

| Chemical Analysis | Verify composition | Spectroscopy |

Heat Treatment Requirements for UNS S32750

- Solution Annealing:

- Temperature: 1020–1100°C (1868–2012°F)

- Cooling Method: Rapid quenching to avoid precipitation.

- Stress Relieving:

- Applied to remove residual stresses from welding.

Types of Buttweld Pipe Fittings

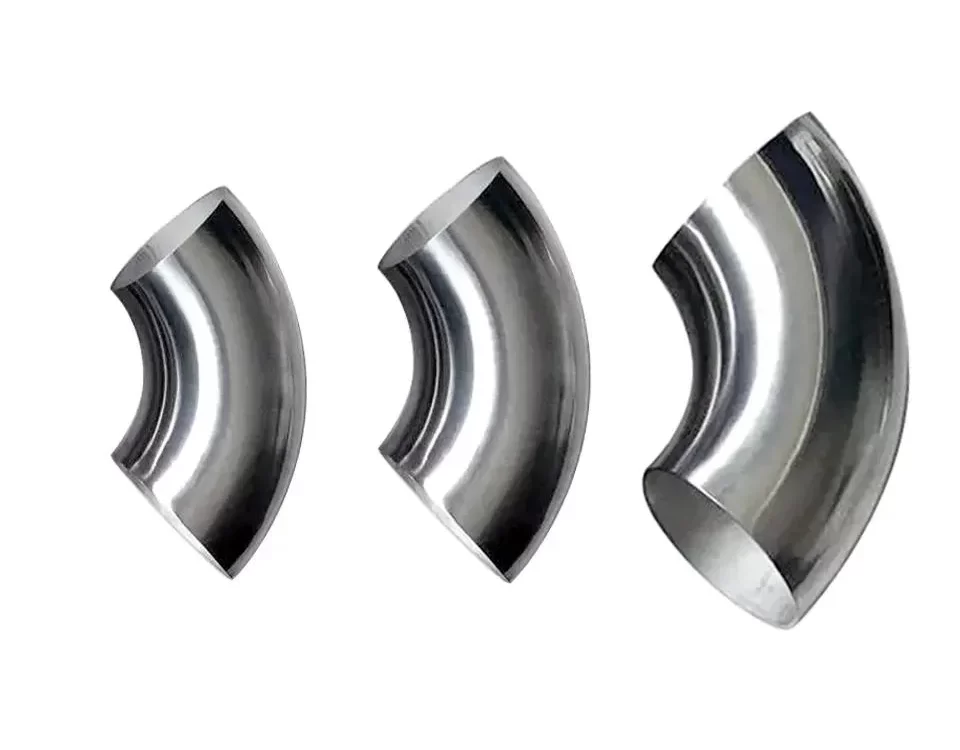

Elbows

Elbows are used to change the direction of flow. They are available in:

- 45°, 90°, and 180° angles.

- Long-radius and short-radius variants.

Tees

Tees divide or combine flow within a piping system and are categorized as:

- Equal Tees

- Reducing Tees

Reducers

Reducers connect pipes of varying diameters. Types include:

- Concentric Reducers

- Eccentric Reducers

Caps and Stub Ends

- Caps: Seal pipe ends.

- Stub Ends: Allow for easy flange connections.

Applications of SAF250 / UNS S32750

- Oil and Gas Industries

- Ideal for subsea pipelines and offshore platforms due to its corrosion resistance.

- Chemical Processing Plants

- Handles aggressive chemicals and high-temperature fluids effectively.

- Marine and Offshore Structures

- Ensures durability in saltwater environments.

Advantages of Using Super Duplex Fittings

- Enhanced Strength: UNS S32750 has nearly double the strength of conventional stainless steels.

- Cost-Effectiveness: Reduced material thickness lowers overall costs without compromising performance.

- Long-Term Durability: Resistant to wear, corrosion, and extreme temperatures.

Manufacturing Process

- Forming: Shaping the raw material into desired fittings.

- Welding: High-quality welds ensure structural integrity.

- Heat Treatment: Optimizes mechanical properties and relieves internal stresses.

Dimensional Standards

ASME B16.9

The most commonly referenced standard for buttweld pipe fittings, ensuring consistent dimensions and tolerances.

| Parameter | Standard Dimensions |

|---|---|

| Wall Thickness | As per pipe schedule |

| Outer Diameter (OD) | Varies with nominal size |

Testing and Quality Assurance

- Non-Destructive Testing (NDT)

- Ultrasonic and radiographic testing ensure defect-free fittings.

- Hydrostatic Testing

- Verifies pressure retention capabilities.

- Mechanical Tests

- Includes tensile and impact testing to confirm strength and ductility.

Global Supply and Sourcing

Key manufacturers and suppliers of UNS S32750 fittings ensure adherence to certifications such as:

- ISO 9001

- PED (Pressure Equipment Directive)

Pricing Factors

Several factors influence the pricing of super duplex fittings:

- Raw Material Costs

- Chromium, nickel, and molybdenum content significantly affect cost.

- Manufacturing Complexity

- Custom designs and tight tolerances increase prices.

FAQs

- What industries use SAF250 / UNS S32750 fittings?

- Commonly used in oil and gas, chemical, and marine industries.

- What makes UNS S32750 superior to conventional stainless steel?

- Its dual-phase structure offers enhanced strength and corrosion resistance.

- Are UNS S32750 fittings weldable?

- Yes, they exhibit excellent weldability when proper techniques are followed.

- What testing is required for ASTM A815 fittings?

- Non-destructive, hydrostatic, and mechanical tests are standard.

- How do I choose the right fitting size?

- Based on pipe diameter, wall thickness, and application requirements.

- What certifications are necessary for suppliers?

- ISO 9001, ASTM compliance, and PED certification.

Conclusion

SAF250 / UNS S32750 super duplex stainless steel buttweld fittings are indispensable for industries demanding high strength, corrosion resistance, and reliability. With advanced manufacturing techniques and strict adherence to ASTM A815 standards, these fittings continue to set benchmarks for performance in critical applications.