Carbon Steel Hollow Section: Square, Rectangular, and Circular

December 11, 2024

ASTM A815 SAF250 / UNS S32750 Super Duplex Buttweld Pipe Fitting

December 17, 2024

A106/ASTM A53 GR.B SMLS Pipe: SCH40 and SCH80 Comprehensive Guide

Introduction

A106/ASTM A53 GR.B seamless (SMLS) pipes are among the most widely used carbon steel pipes in industries such as oil and gas, petrochemical, construction, and power generation. These pipes are known for their excellent mechanical properties, high-temperature resistance, and versatility. Designed to withstand pressure, temperature, and corrosive environments, they are commonly used for transporting fluids and gases in both industrial and residential applications.

This article provides an in-depth exploration of A106/ASTM A53 GR.B seamless pipes, focusing on Schedule 40 (SCH40) and Schedule 80 (SCH80). We will cover their specifications, manufacturing processes, applications, advantages, and detailed tables for dimensions and properties. By the end, you’ll have a comprehensive understanding of these pipes and their role in various industries.

What Are A106/ASTM A53 GR.B SMLS Pipes?

A106 and A53 Standards Overview

- ASTM A106: Covers seamless carbon steel pipes for high-temperature service. It is commonly used in industries requiring pipes to handle extreme heat and pressure.

- ASTM A53: Covers seamless and welded carbon steel pipes for general use, including mechanical and pressure applications.

Both standards specify Grade B as a medium-strength grade with excellent mechanical properties, making it the most commonly used grade.

Key Features of GR.B SMLS Pipes

- Seamless Construction: Manufactured without welds, ensuring uniform strength and resistance to pressure.

- High-Temperature Resistance: Suitable for applications involving high heat.

- Versatility: Available in various schedules (wall thicknesses) to meet diverse application requirements.

- Durability: Resistant to cracking, deformation, and fatigue under stress.

SCH40 and SCH80: Understanding Pipe Schedules

The schedule of a pipe refers to its wall thickness, which affects its pressure rating and mechanical properties.

- Schedule 40 (SCH40): Standard wall thickness, suitable for low to medium pressure applications.

- Schedule 80 (SCH80): Thicker wall, designed for higher pressure and more demanding applications.

The wall thickness increases with the schedule, while the outer diameter remains constant.

Chemical Composition of A106/ASTM A53 GR.B Pipes

The chemical composition of GR.B pipes ensures their strength, ductility, and resistance to corrosion.

| Element | ASTM A106 GR.B (%) | ASTM A53 GR.B (%) |

|---|---|---|

| Carbon (C) | ≤ 0.30 | ≤ 0.30 |

| Manganese (Mn) | 0.29–1.06 | 1.20 max |

| Phosphorus (P) | ≤ 0.035 | ≤ 0.05 |

| Sulfur (S) | ≤ 0.035 | ≤ 0.045 |

| Silicon (Si) | ≥ 0.10 | Not specified |

| Copper (Cu) | Not specified | ≤ 0.40 |

| Nickel (Ni) | Not specified | ≤ 0.40 |

| Chromium (Cr) | Not specified | ≤ 0.40 |

| Molybdenum (Mo) | Not specified | ≤ 0.15 |

Mechanical Properties of A106/ASTM A53 GR.B Pipes

| Property | ASTM A106 GR.B | ASTM A53 GR.B |

|---|---|---|

| Tensile Strength | ≥ 415 MPa (60,000 psi) | ≥ 415 MPa (60,000 psi) |

| Yield Strength | ≥ 240 MPa (35,000 psi) | ≥ 240 MPa (35,000 psi) |

| Elongation (%) | 20–22 | 20–22 |

| Hardness (HBW) | ≤ 241 | ≤ 241 |

Manufacturing Process of Seamless Pipes

The production of seamless pipes involves several steps to ensure high quality and precision:

1. Billet Preparation

- A solid steel billet is selected based on the desired grade and dimensions.

- The billet is heated to a high temperature to make it malleable.

2. Piercing

- The heated billet is pierced using a rotary piercing mill to create a hollow tube.

- This process forms the basic shape of the seamless pipe.

3. Rolling and Sizing

- The hollow tube is rolled and stretched to achieve the desired dimensions (outer diameter and wall thickness).

- Sizing mills are used to ensure precise tolerances.

4. Heat Treatment

- The pipe undergoes heat treatment processes such as annealing, normalizing, or quenching and tempering to enhance its mechanical properties.

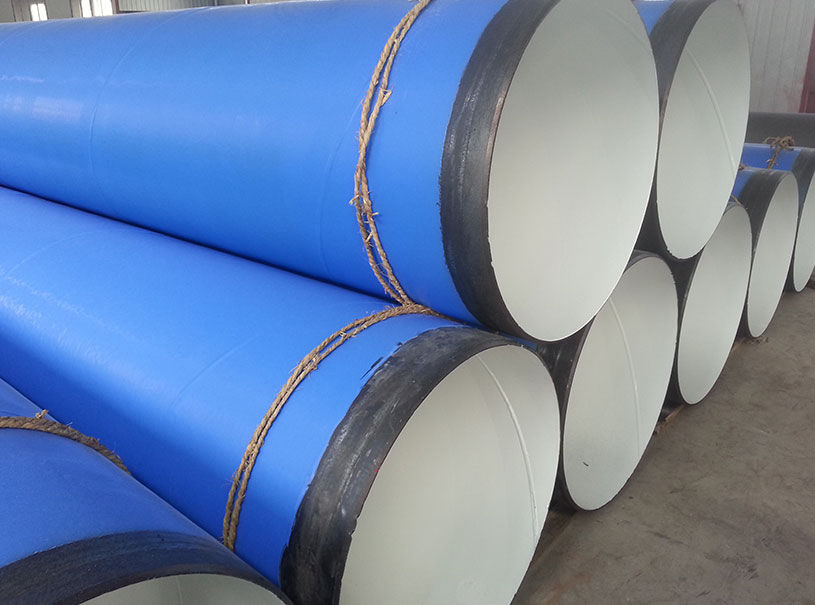

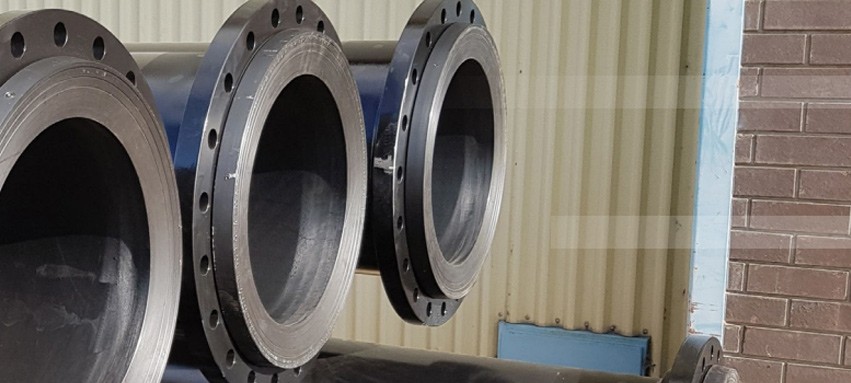

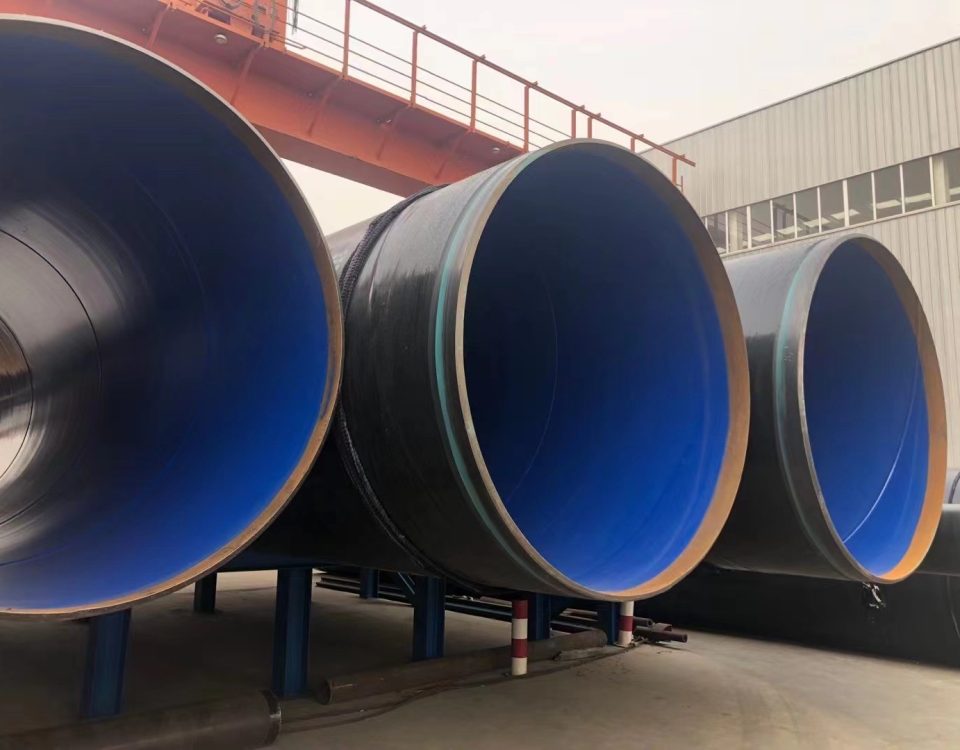

5. Finishing

- The pipe is cut to the required length and inspected for quality.

- Surface treatments, such as galvanization or painting, may be applied for corrosion resistance.

Dimensions and Specifications of SCH40 and SCH80 Pipes

1. Schedule 40 (SCH40) Dimensions

| Nominal Pipe Size (NPS) | Outer Diameter (OD) (mm) | Wall Thickness (mm) | Weight (kg/m) |

|---|---|---|---|

| 1/2″ | 21.3 | 2.77 | 1.27 |

| 1″ | 33.4 | 3.38 | 2.49 |

| 2″ | 60.3 | 3.91 | 5.44 |

| 4″ | 114.3 | 6.02 | 14.98 |

| 6″ | 168.3 | 7.11 | 23.93 |

| 8″ | 219.1 | 8.18 | 37.62 |

2. Schedule 80 (SCH80) Dimensions

| Nominal Pipe Size (NPS) | Outer Diameter (OD) (mm) | Wall Thickness (mm) | Weight (kg/m) |

|---|---|---|---|

| 1/2″ | 21.3 | 3.73 | 1.56 |

| 1″ | 33.4 | 4.55 | 3.32 |

| 2″ | 60.3 | 5.54 | 7.39 |

| 4″ | 114.3 | 8.56 | 20.72 |

| 6″ | 168.3 | 10.97 | 33.96 |

| 8″ | 219.1 | 12.70 | 53.14 |

Applications of A106/ASTM A53 GR.B SMLS Pipes

1. Oil and Gas Industry

- Pipeline Systems: Used for transporting oil, gas, and other hydrocarbons.

- High-Temperature Lines: Suitable for steam and process piping in refineries.

2. Power Plants

- Boiler Tubes: Used in high-pressure and high-temperature environments.

- Heat Exchangers: Ensure efficient heat transfer in power generation systems.

3. Construction

- Structural Support: Used in building frameworks and columns.

- Water Distribution: Suitable for potable and non-potable water systems.

4. Chemical and Petrochemical

- Process Piping: Used in chemical plants for transporting corrosive fluids.

- Pressure Vessels: Suitable for high-pressure applications.

5. Automotive and Machinery

- Hydraulic Systems: Used in hydraulic and pneumatic systems for their strength and durability.

- Mechanical Components: Used in the fabrication of machine parts.

Advantages of A106/ASTM A53 GR.B SMLS Pipes

- Seamless Construction: Ensures uniform strength and eliminates weak points caused by welds.

- High-Temperature Resistance: Suitable for extreme heat and pressure applications.

- Versatility: Available in various schedules and sizes for diverse applications.

- Durability: Resistant to cracking, deformation, and fatigue under stress.

- Corrosion Resistance: Can be coated or galvanized for enhanced protection.

Maintenance and Inspection of SMLS Pipes

1. Regular Inspection

- Visual Inspection: Check for surface defects such as cracks, dents, or corrosion.

- Non-Destructive Testing (NDT): Use ultrasonic or radiographic testing to detect internal defects.

2. Cleaning

- Remove dirt, debris, and corrosion using appropriate cleaning methods.

- Apply protective coatings to prevent rust and corrosion.

3. Repair or Replacement

- Replace damaged or worn-out pipes to maintain safety and performance.

- Repair minor defects using approved methods.

Comparison of SCH40 and SCH80 Pipes

| Feature | Schedule 40 (SCH40) | Schedule 80 (SCH80) |

|---|---|---|

| Wall Thickness | Standard | Thicker |

| Pressure Rating | Medium | High |

| Weight | Lighter | Heavier |

| Applications | General-purpose piping | High-pressure systems |

| Cost | Lower | Higher |

Carbon steel seamless pipe, ASTM A106 Gr.B SCH40 Prices

| Stock Price (Dec,2024) | |||||||

| COMMODITY | SPECIFICATION | MATERIAL | END | FOB | |||

| OD | WT | Length | TYPE | Tianjin Port | |||

| Inch | mm | mm | M/Pcs | USD/TON | |||

| SMLS PIPE, SCH40 | ,1/4 | 13.7 | 2.24 | 6 | A106/ASTM A53 GR.B | PE | $1,100.00 |

| SMLS PIPE, SCH40 | ,3/8 | 17.1 | 2.31 | 6 | A106/ASTM A53 GR.B | PE | $950.00 |

| SMLS PIPE, SCH40 | ,1/2 | 21.3 | 2.77 | 6 | A106/ASTM A53 GR.B | PE | $800.00 |

| SMLS PIPE, SCH40 | ,3/4 | 26.7 | 2.87 | 6 | A106/ASTM A53 GR.B | PE | $750.00 |

| SMLS PIPE, SCH40 | 1 | 33.4 | 3.38 | 6 | A106/ASTM A53 GR.B | PE | $680.00 |

| SMLS PIPE, SCH40 | ,1-1/4 | 42.2 | 3.56 | 6 | A106/ASTM A53 GR.B | PE | $620.00 |

| SMLS PIPE, SCH40 | ,1-1/2 | 48.3 | 3.68 | 6 | A106/ASTM A53 GR.B | PE | $610.00 |

| SMLS PIPE, SCH40 | 2 | 60.3 | 3.91 | 6 | A106/ASTM A53 GR.B | BE | $610.00 |

| SMLS PIPE, SCH40 | ,2-1/2 | 73 | 5.16 | 6 | A106/ASTM A53 GR.B | BE | $600.00 |

| SMLS PIPE, SCH40 | 3 | 88.9 | 5.49 | 6 | A106/ASTM A53 GR.B | BE | $600.00 |

| SMLS PIPE, SCH40 | 4 | 114.3 | 6.02 | 6 | A106/ASTM A53 GR.B | BE | $600.00 |

| SMLS PIPE, SCH40 | 5 | 141.3 | 6.55 | 6 | A106/ASTM A53 GR.B | BE | $590.00 |

| SMLS PIPE, SCH40 | 6 | 168.3 | 7.11 | 6 | A106/ASTM A53 GR.B | BE | $580.00 |

| SMLS PIPE, SCH40 | 8 | 219.1 | 8.18 | 6 | A106/ASTM A53 GR.B | BE | $580.00 |

| SMLS PIPE, SCH40 | 10 | 273 | 9.27 | 6 | A106/ASTM A53 GR.B | BE | $575.00 |

| SMLS PIPE, SCH40 | 12 | 323.8 | 10.31 | 6 | A106/ASTM A53 GR.B | BE | $580.00 |

| SMLS PIPE, SCH40 | 14 | 355.6 | 11.13 | 6 | A106/ASTM A53 GR.B | BE | $620.00 |

| SMLS PIPE, SCH40 | 16 | 406.4 | 12.7 | 6 | A106/ASTM A53 GR.B | BE | $620.00 |

| SMLS PIPE, SCH40 | 18 | 457.2 | 14.27 | 6 | A106/ASTM A53 GR.B | BE | $620.00 |

| SMLS PIPE, SCH40 | 20 | 508 | 15.09 | 6 | A106/ASTM A53 GR.B | BE | $660.00 |

| SMLS PIPE, SCH40 | 24 | 609.6 | 17.48 | 6 | A106/ASTM A53 GR.B | BE | $670.00 |

| SMLS PIPE, SCH80 | ,1/2 | 21.3 | 3.73 | 6 | A106/ASTM A53 GR.B | PE | $780.00 |

| SMLS PIPE, SCH80 | ,3/4 | 26.7 | 3.91 | 6 | A106/ASTM A53 GR.B | PE | $750.00 |

| SMLS PIPE, SCH80 | 1 | 33.4 | 4.55 | 6 | A106/ASTM A53 GR.B | PE | $650.00 |

| SMLS PIPE, SCH80 | ,1-1/4 | 42.2 | 4.85 | 6 | A106/ASTM A53 GR.B | PE | $550.00 |

| SMLS PIPE, SCH80 | ,1-1/2 | 48.3 | 5.08 | 6 | A106/ASTM A53 GR.B | PE | $610.00 |

| SMLS PIPE, SCH80 | 2 | 60.3 | 5.54 | 6 | A106/ASTM A53 GR.B | BE | $610.00 |

| SMLS PIPE, SCH80 | ,2-1/2 | 73 | 7.01 | 6 | A106/ASTM A53 GR.B | BE | $605.00 |

| SMLS PIPE, SCH80 | 3 | 88.9 | 7.62 | 6 | A106/ASTM A53 GR.B | BE | $600.00 |

| SMLS PIPE, SCH80 | 4 | 114.3 | 8.56 | 6 | A106/ASTM A53 GR.B | BE | $600.00 |

| SMLS PIPE, SCH80 | 5 | 141.3 | 9.53 | 6 | A106/ASTM A53 GR.B | BE | $590.00 |

| SMLS PIPE, SCH80 | 6 | 168.3 | 10.97 | 6 | A106/ASTM A53 GR.B | BE | $580.00 |

| SMLS PIPE, SCH80 | 8 | 219.1 | 12.7 | 6 | A106/ASTM A53 GR.B | BE | $570.00 |

| SMLS PIPE, SCH80 | 10 | 273 | 15.09 | 6 | A106/ASTM A53 GR.B | BE | $565.00 |

| SMLS PIPE, SCH80 | 12 | 323.8 | 17.48 | 6 | A106/ASTM A53 GR.B | BE | $597.00 |

| SMLS PIPE, SCH80 | 14 | 355.6 | 19.05 | 6 | A106/ASTM A53 GR.B | BE | $640.00 |

| SMLS PIPE, SCH80 | 16 | 406.4 | 21.44 | 6 | A106/ASTM A53 GR.B | BE | $640.00 |

| SMLS PIPE, SCH80 | 18 | 457.2 | 23.88 | 6 | A106/ASTM A53 GR.B | BE | |

| SMLS PIPE, SCH80 | 20 | 508 | 26.19 | 6 | A106/ASTM A53 GR.B | BE | |

| SMLS PIPE, SCH80 | 24 | 609.6 | 30.96 | 6 | A106/ASTM A53 GR.B | BE | |

| If you have puchasing plan, we will try to apply a discount from our GM, Any other inquires please send to us. | |||||||

| Our Advantage: | |||||||

| 1.Integrated steel pipes supplier supporting lowest price in China. | |||||||

| 2.Financial supports, the payment term could be acceptable such as L/C, T/T. | |||||||

| 3.Good quality to accept any third party inspection. | |||||||

| 4.The financial yearly reports in latest 3 years. | |||||||

| 5.Full system of after sales records(tracking purpose). | |||||||

| 6.Full bank supported company with a perfect line of Credit “AAAAA”. | |||||||

A106/ASTM A53 GR.B seamless pipes, particularly in SCH40 and SCH80, are essential components in industries requiring high strength, durability, and resistance to extreme conditions. Their seamless construction and excellent mechanical properties make them ideal for applications ranging from oil and gas pipelines to structural frameworks and high-temperature systems.

By understanding their specifications, dimensions, and applications, you can select the right pipe for your project and ensure its success. Whether you need a standard wall thickness for general use or a thicker wall for high-pressure applications, GR.B seamless pipes offer a reliable and cost-effective solution.

FAQ

1. What is the difference between ASTM A106 and ASTM A53?

- ASTM A106 is designed for high-temperature service, while ASTM A53 is used for general-purpose applications, including mechanical and pressure systems.

2. What are SCH40 and SCH80 pipes?

SCH40 and SCH80 refer to the wall thickness of the pipe. SCH80 pipes have thicker walls and higher pressure ratings than SCH40 pipes.

3. What are the common applications of A106/ASTM A53 GR.B pipes?

These pipes are used in oil and gas pipelines, power plants, construction frameworks, chemical plants, and hydraulic systems.

4. How are seamless pipes manufactured?

Seamless pipes are made by piercing a solid steel billet to create a hollow tube, followed by rolling, sizing, and heat treatment.

5. How can corrosion in seamless pipes be prevented?

Corrosion can be prevented using protective coatings (galvanization, painting), cathodic protection, and regular maintenance.