The Benefits of AWWA C210 Liquid Epoxy Coating for Pipeline Protection

February 12, 2024

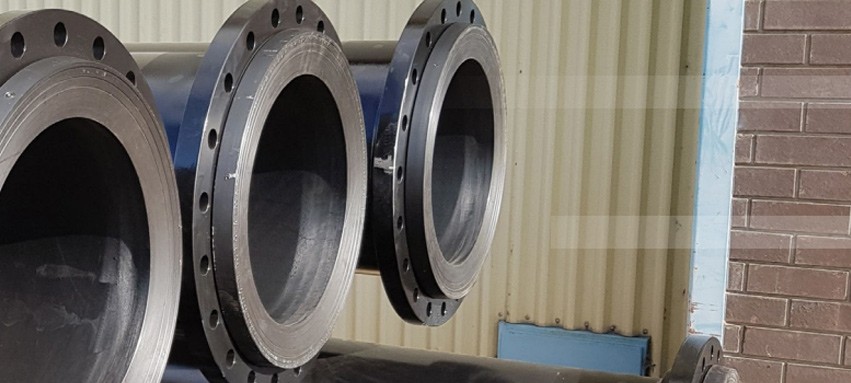

The A105 Forge Blind BL Flange: A Comprehensive Guide

February 16, 2024AWWA C210: Liquid/Epoxy Coatings and Linings for Steel Water Pipe and Fittings

AWWA C210 is a standard developed by the American Water Works Association (AWWA) that focuses on the application of liquid/epoxy coatings and linings for steel water pipes and fittings. This standard plays a crucial role in ensuring the integrity and longevity of drinking water infrastructure in the United States. In this section, we will explore the key aspects of AWWA C210, including its minimum requirements, application guidelines, testing requirements, and real-world examples.

Drinking Water Infrastructure in the United States

Drinking water infrastructure in the United States is a critical component of public health and safety. It encompasses a vast network of pipes, fittings, and treatment facilities that deliver clean and safe drinking water to communities across the country. Steel pipes are widely used in the water industry due to their strength and durability. However, to protect these pipes from corrosion and ensure the quality of the water being transported, appropriate coatings and linings are necessary.

Types of Steel Pipes in the Water Industry and Typical Coatings that Meet AWWA C210

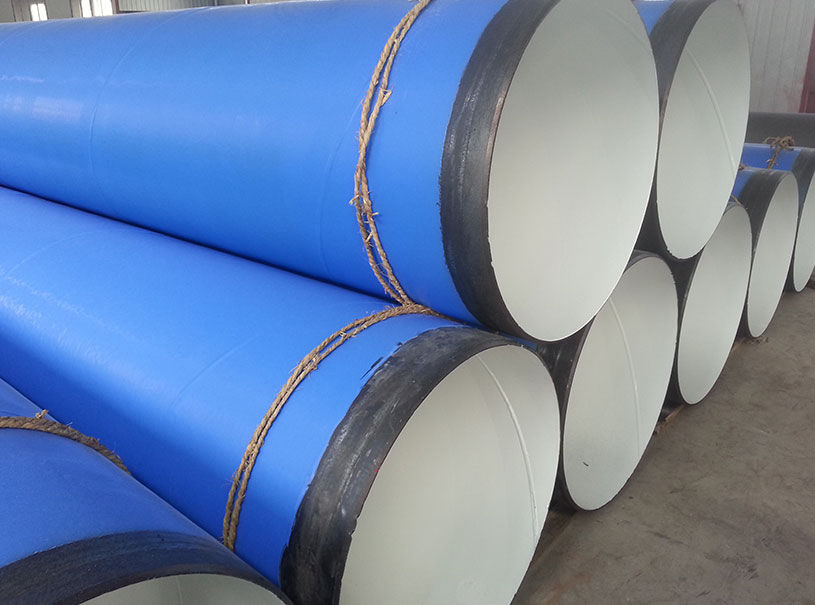

In the water industry, various types of steel pipes are used, including welded steel pipes, spiral submerged-arc welded (SSAW) steel pipes, and seamless steel pipes. These pipes can be coated with different materials to provide corrosion protection and maintain water quality. Some typical coatings that meet the requirements of AWWA C210 include liquid epoxy coatings, fusion-bonded epoxy (FBE) coatings, and polyurethane coatings.

Liquid epoxy coatings are widely used in the water industry due to their excellent adhesion, chemical resistance, and durability. These coatings provide a protective barrier between the steel surface and the water, preventing corrosion and maintaining the quality of the drinking water.

Minimum Requirements for AWWA C210

AWWA C210 establishes the minimum requirements for the application of liquid/epoxy coatings and linings for steel water pipes and fittings. These requirements ensure that the coatings and linings provide effective corrosion protection and meet the necessary quality standards. Some of the key minimum requirements specified by AWWA C210 include:

- Adhesion: The coating should have excellent adhesion to the steel surface to prevent delamination or detachment.

- Chemical Resistance: The coating should be resistant to chemicals commonly found in drinking water to maintain water quality.

- Thickness: The coating should have a minimum thickness to provide sufficient protection against corrosion.

- Cure Time: The coating should have a specified cure time to ensure proper bonding and durability.

- Surface Preparation: The steel surface should be properly prepared before the application of the coating to ensure optimal adhesion and performance.

By adhering to these minimum requirements, the coatings and linings applied to steel water pipes and fittings can effectively protect the infrastructure and maintain the quality of the drinking water.

Application of Coatings per AWWA C210

AWWA C210 provides guidelines for the application of liquid/epoxy coatings and linings for steel water pipes and fittings. These guidelines cover various aspects of the application process, including surface preparation, coating application methods, curing procedures, and quality control measures. The application of coatings per AWWA C210 involves the collaboration of multiple stakeholders, including the constructor, the manufacturer of the coating, and the purchaser.

The constructor is responsible for ensuring that the surface preparation is carried out according to the specified requirements. This includes cleaning the steel surface, removing any contaminants, and achieving the desired surface profile. The manufacturer of the coating provides detailed instructions on the application process, including the recommended application methods, curing temperatures, and curing times. The purchaser, typically a water utility or a contractor, ensures that the coating application is carried out in compliance with AWWA C210 and meets the necessary quality standards.

The Growth of AWWA C210 and Use in AWWA D102

Over the years, AWWA C210 has gained significant recognition and acceptance in the water industry. Its guidelines and requirements have become widely adopted by water utilities, contractors, and coating manufacturers. AWWA C210 has also been referenced in other AWWA standards, such as AWWA D102, which focuses on the coating and lining systems for steel water pipelines.

The use of AWWA C210-approved coatings in AWWA D102-compliant projects ensures consistency, quality, and long-term performance of the coatings applied to steel water pipes and fittings. This integration of standards promotes the use of reliable and proven coating systems, contributing to the overall reliability and sustainability of drinking water infrastructure.

Testing Requirements for Coatings per AWWA C210

AWWA C210 specifies testing requirements to ensure the quality and performance of coatings applied to steel water pipes and fittings. These testing requirements include:

- Adhesion Testing: Determines the strength of the bond between the coating and the steel surface.

- Chemical Resistance Testing: Evaluates the resistance of the coating to chemicals commonly found in drinking water.

- Thickness Measurement: Verifies the thickness of the applied coating to ensure it meets the specified

Quality Control Measures per AWWA C210

To ensure the proper application of coatings and linings in accordance with AWWA C210, quality control measures are essential. These measures help maintain consistency, adherence to standards, and the overall quality of the coating application process. Some of the key quality control measures specified by AWWA C210 include:

- Inspection and Documentation: Regular inspections should be conducted during the surface preparation and coating application process. This includes documenting the surface preparation methods, coating application parameters, and curing procedures. Inspections help identify any deviations from the specified requirements and ensure that corrective actions are taken promptly.

- Coating Thickness Measurement: Coating thickness is a critical factor in providing effective corrosion protection. Regular measurements should be taken to verify that the applied coating meets the minimum thickness requirements specified by AWWA C210. This can be done using non-destructive testing methods such as magnetic induction or ultrasonic thickness gauges.

- Adhesion Testing: Adhesion testing is performed to assess the strength of the bond between the coating and the steel surface. Various methods can be used, including pull-off tests and cross-cut tests. These tests help ensure that the coating has proper adhesion and will not delaminate or detach over time.

- Cure Time Verification: The curing process is crucial for the development of the coating’s physical and chemical properties. It is essential to verify that the coating has been cured for the specified duration and at the recommended temperature. This can be done by conducting cure time verification tests, such as hardness tests or solvent resistance tests.

- Chemical Resistance Testing: Coatings applied to steel water pipes and fittings should exhibit resistance to chemicals commonly found in drinking water. Chemical resistance testing helps evaluate the coating’s ability to withstand exposure to these chemicals without degradation or loss of performance.

By implementing these quality control measures, the coating application process can be closely monitored, ensuring that the coatings and linings meet the necessary standards and provide long-lasting protection to the steel water infrastructure.

Real-World Example that Would Benefit from AWWA C210 Approved Coatings

To illustrate the significance of AWWA C210-approved coatings, let’s consider a real-world example. Imagine a water utility in a coastal region that relies on steel pipes to transport drinking water from a treatment plant to various communities. The proximity to saltwater and the corrosive nature of the environment pose significant challenges to the longevity of the steel pipes.

By applying AWWA C210-approved coatings to the steel pipes, the water utility can enhance the corrosion resistance of the infrastructure. The liquid epoxy coatings, for instance, provide a protective barrier that prevents the corrosive elements from reaching the steel surface. This helps extend the lifespan of the pipes, reduce maintenance costs, and ensure the delivery of clean and safe drinking water to the communities.

In this scenario, AWWA C210-approved coatings play a vital role in preserving the integrity of the water infrastructure and mitigating the effects of corrosion. The adherence to the standard’s guidelines and requirements ensures that the coatings applied meet the necessary quality standards and provide long-term protection.

Frequently Asked Questions (FAQ)

1. What is the purpose of AWWA C210?

AWWA C210 establishes the minimum requirements for the application of liquid/epoxy coatings and linings for steel water pipes and fittings. Its purpose is to ensure the integrity, longevity, and corrosion protection of drinking water infrastructure.

2. What are the typical coatings that meet AWWA C210?

Some typical coatings that meet the requirements of AWWA C210 include liquid epoxy coatings, fusion-bonded epoxy (FBE) coatings, and polyurethane coatings.

3. Who is responsible for the application of coatings per AWWA C210?

The application of coatings per AWWA C210 involves the collaboration of multiple stakeholders, including the constructor, the manufacturer of the coating, and the purchaser (typically a water utility or a contractor).

4. What are the testing requirements for coatings per AWWA C210?

AWWA C210 specifies testing requirements such as adhesion testing, chemical resistance testing, and thickness measurement to ensure the quality and performance of the coatings applied to steel water pipes and fittings.

5. How do AWWA C210-approved coatings benefit real-world applications?

AWWA C210-approved coatings provide effective corrosion protection, extend the lifespan of steel water infrastructure, reduce maintenance costs, and ensure the delivery of clean and safe drinking water to communities.

In conclusion, AWWA C210 plays a crucial role in the protection and maintenance of steel water pipes and fittings in the drinking water industry. By adhering to its guidelines and requirements, water utilities, contractors, and coating manufacturers can ensure the integrity and longevity of the infrastructure while maintaining the quality of the drinking water. The application of AWWA C210-approved coatings provides effective corrosion protection, reduces maintenance costs, and