AWWA C210 Epoxy Coating Pipeline and Fittings for Water

February 12, 2024

UNS S31603 316L steel Pipe | seamless & welded stainless

February 20, 2024

The A105 Forge Blind BL Flange: A Comprehensive Guide

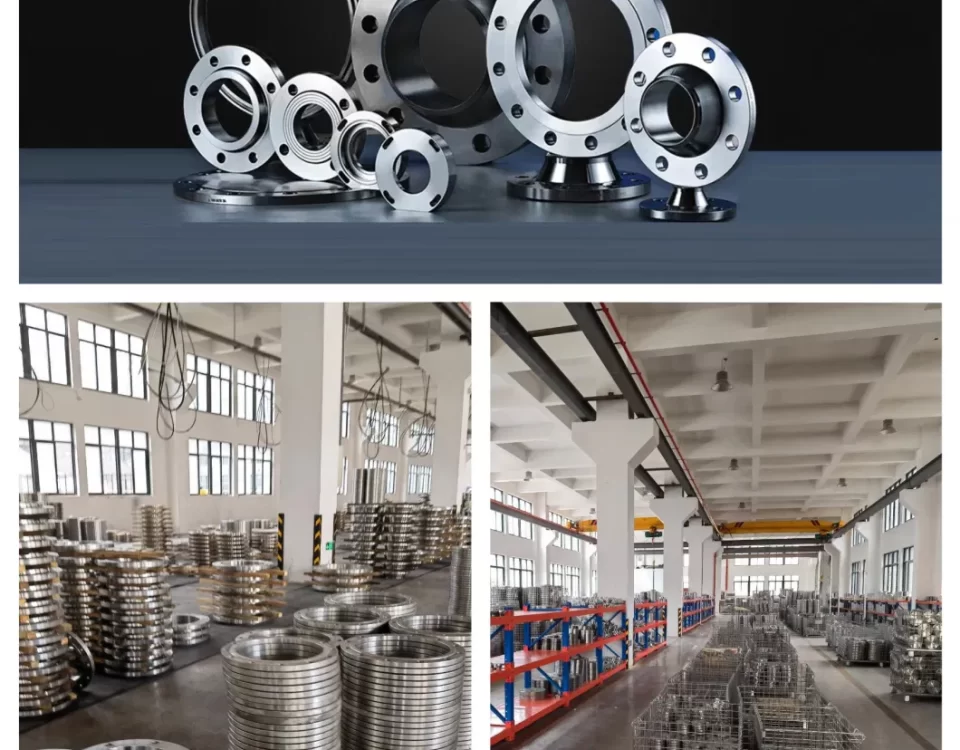

Introduction

In the world of industrial piping systems, flanges play a crucial role in connecting pipes, valves, and other equipment. One such flange is the A105 Forge Blind BL Flange. This article aims to provide a comprehensive guide to this specific type of flange, including its features, specifications, and applications. Whether you are a professional in the industry or simply curious about flanges, this article will equip you with the knowledge you need.

Understanding the A105 Forge Blind BL Flange

The A105 Forge Blind BL Flange is a type of blind flange, which means it is designed to seal the end of a pipe or vessel. It is commonly used in applications where the pipe or vessel needs to be closed off, preventing the flow of fluid or gas. The A105 Forge Blind BL Flange is available in various sizes, ranging from 1/2″ to 250″, making it suitable for a wide range of piping systems.

Key Specifications

- Type: Blind flange

- Size: 1/2″-250″

- Face: FF, RF, RTJ

- Manufacturing Way: Forging

- Standard: ANSI B16.5, EN1092-1, SABA1123, JIS B2220, DIN, GOST, UNI, AS2129, API 6A, etc.

- Material: Carbon steel, Stainless steel, Pipeline steel, Cr-Mo alloy

Pressure and Standard

The A105 Forge Blind BL Flange can withstand varying pressure levels, ranging from 150# to 2500#, PN0.6 to PN400, 5K to 40K, and API 2000 to 15000. It complies with industry standards such as ANSI B16.5, EN1092-1, SABA1123, JIS B2220, DIN, GOST, UNI, AS2129, and API 6A.

Wall Thickness and Material

The wall thickness of the A105 Forge Blind BL Flange can be customized based on specific requirements. It is available in different thicknesses, including SCH5S, SCH10S, SCH10, SCH40S, STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS, and more.

The material used for the A105 Forge Blind BL Flange depends on the application and the environment it will be exposed to. The options include:

- Stainless steel: A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571, 1.4541, 254Mo, and more.

- Carbon steel: A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70, and more.

- Duplex stainless steel: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462, 1.4410, 1.4501, and more.

- Pipeline steel: A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80, and more.

- Nickel alloy: Inconel600, Inconel625, Inconel690, Incoloy800, Incoloy 825, Incoloy 800H, C22, C-276, Monel400, Alloy20, and more.

- Cr-Mo alloy: A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3, 15Crmo, and more.

Applications of the A105 Forge Blind BL Flange

The A105 Forge Blind BL Flange finds its applications in various industries due to its versatility and reliability. Some common applications include:

- Oil and Gas Industry: The A105 Forge Blind BL Flange is widely used in oil and gas pipelines, refineries, and petrochemical plants. It ensures the safe and efficient flow of fluids and gases in these critical systems.

- Power Generation: Power plants, including thermal, nuclear, and renewable energy facilities, utilize the A105 Forge Blind BL Flange for connecting pipes and equipment. It helps in maintaining the integrity of the piping system, even under high-pressure conditions.

- ChemicalProcessing: In chemical processing plants, the A105 Forge Blind BL Flange is used to connect pipes and vessels that transport various chemicals. Its resistance to corrosion and high temperatures makes it suitable for such demanding environments.

- Water Treatment: The A105 Forge Blind BL Flange is also utilized in water treatment plants, where it helps in connecting pipes and equipment for the purification and distribution of water. Its durability and leak-proof design ensure the efficient operation of the water treatment system.

- Construction and Infrastructure: The construction industry often requires the use of the A105 Forge Blind BL Flange for plumbing and HVAC systems in commercial and residential buildings. It provides a secure and reliable connection between pipes, ensuring the smooth flow of water and other fluids.

Frequently Asked Questions (FAQ)

1. What is the difference between FF, RF, and RTJ faces in the A105 Forge Blind BL Flange?

The A105 Forge Blind BL Flange is available with three different face types: FF (Flat Face), RF (Raised Face), and RTJ (Ring Type Joint). The FF face provides a flat surface for the flange to mate with, while the RF face has a raised surface to create a better seal. The RTJ face features a groove and a metal ring gasket, which provides a tight and leak-proof connection.

2. Can the A105 Forge Blind BL Flange be used for high-pressure applications?

Yes, the A105 Forge Blind BL Flange is designed to withstand high-pressure conditions. It is available in pressure ratings ranging from 150# to 2500#, PN0.6 to PN400, 5K to 40K, and API 2000 to 15000. However, it is important to select the appropriate flange class and material based on the specific requirements of the application.

3. What are the advantages of using a forged A105 Forge Blind BL Flange?

Forging is a manufacturing process that involves shaping metal by applying compressive forces. The A105 Forge Blind BL Flange is forged, which offers several advantages. These include:

- Enhanced Strength: Forged flanges have superior strength compared to flanges made through other manufacturing processes. This makes them suitable for high-pressure and high-temperature applications.

- Improved Structural Integrity: The forging process eliminates internal voids and porosity, resulting in a more structurally sound flange.

- Better Fatigue Resistance: Forged flanges have excellent fatigue resistance, making them suitable for applications that involve cyclic loading.

- Consistent Grain Structure: The forging process aligns the grain structure of the metal, resulting in improved mechanical properties and overall performance.

4. Can the A105 Forge Blind BL Flange be customized according to specific requirements?

Yes, the A105 Forge Blind BL Flange can be customized based on specific requirements. This includes the size, face type, pressure rating, wall thickness, and material. Customization ensures that the flange meets the exact needs of the application, providing a reliable and efficient connection.

5. How can I ensure the proper installation of the A105 Forge Blind BL Flange?

Proper installation of the A105 Forge Blind BL Flange is essential to ensure its performance and longevity. Here are some key steps to follow:

- Clean the flange surfaces and ensure they are free from any debris or contaminants.

- Apply a suitable gasket to the flange face to create a tight seal.

- Align the flange with the pipe or vessel and insert the bolts.

- Gradually tighten the bolts in a crisscross pattern to ensure even distribution of pressure.

- Use a torque wrench to achieve the recommended bolt torque.

- Inspect the flange after installation to ensure there are no leaks or visible defects.

Conclusion

The A105 Forge Blind BL Flange is a versatile and reliable component in industrial piping systems. Its features, specifications, and applications make it a valuable asset in various industries, including oil and gas, power generation, chemical processing, water treatment, and construction. By understanding its key characteristics and proper installation techniques, professionals can make informed decisions and ensure the optimal performance of their piping systems.