ASTM A500 Steel Hollow Sections for Structural

November 4, 2023

Difference between 304 and 420 stainless steel pipe?

November 6, 2023Stainless Hollow Section: A554 Gr 409/409L, A554 Gr 316, A554 Gr 202 Hollow Section

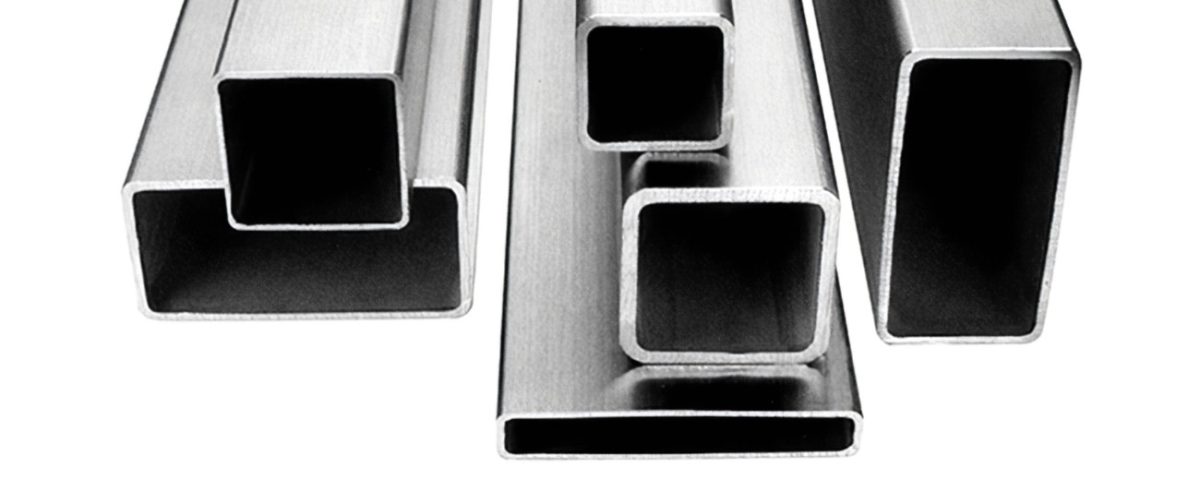

Stainless hollow sections are commonly used in a wide range of applications such as architecture, construction, and mechanical applications. The most widely used stainless steel grades in hollow sections are 409/409L, 316, and 202. These stainless steel grades fall under the American Society for Testing and Materials (ASTM) A554 specification, which covers welded stainless steel tubing for mechanical applications.

A554 Gr 409/409L Hollow Section

Grade 409/409L is a ferritic stainless steel that offers good mechanical properties and high-temperature corrosion resistance. It is commonly used in automotive exhaust systems.

Chemical Composition

- Carbon (C): 0.08% max

- Silicon (Si): 1.00% max

- Manganese (Mn): 1.00% max

- Phosphorous (P): 0.045% max

- Sulfur (S): 0.03% max

- Chromium (Cr): 10.5-11.7%

- Titanium (Ti): 6x(C+N) min, 0.75% max

A554 Gr 316 Hollow Section

Grade 316 is an austenitic stainless steel that has excellent corrosion resistance and high strength. It is commonly used in marine applications and other harsh environments.

Chemical Composition

- Carbon (C): 0.08% max

- Silicon (Si): 1.00% max

- Manganese (Mn): 2.00% max

- Phosphorous (P): 0.045% max

- Sulfur (S): 0.03% max

- Chromium (Cr): 16.0-18.0%

- Nickel (Ni): 10.0-14.0%

- Molybdenum (Mo): 2.00-3.00%

A554 Gr 202 Hollow Section

Grade 202 is a type of Cr-Ni-Mn stainless steel which can be used in similar applications as the 201 grade but provides higher yield strength.

Chemical Composition

- Carbon (C): 0.15% max

- Silicon (Si): 1.00% max

- Manganese (Mn): 7.50-10.00%

- Phosphorous (P): 0.060% max

- Sulfur (S): 0.03% max

- Chromium (Cr): 17.0-19.0%

- Nickel (Ni): 4.00-6.00%

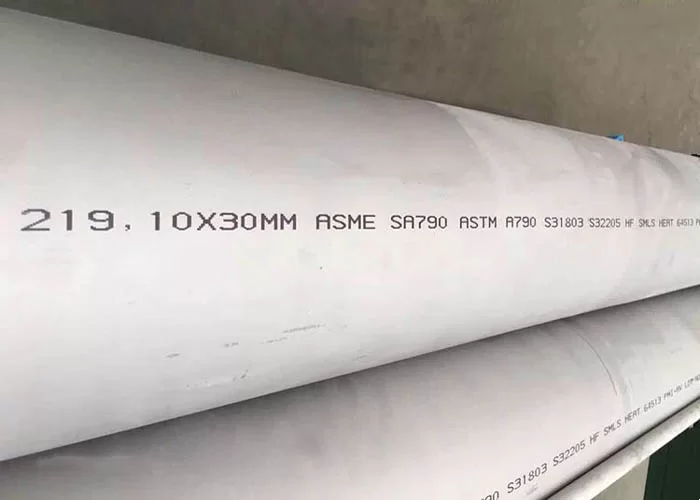

Size Thickness

The size thickness of the hollow section tubes can vary based on the needs of the specific application. However, common thickness ranges for these grades of stainless steel are:

- 409/409L: 0.5mm to 5mm

- 316: 0.5mm to 5mm

- 202: 0.5mm to 5mm

Mechanical Properties of Stainless Hollow Section: A554 Gr 409/409L, A554 Gr 316, A554 Gr 202

Mechanical properties of stainless steel materials can be quite complex as they depend on a host of factors including the specific composition of the alloy, heat treatment, and processing methods. However, generally speaking, the following are typical mechanical properties for the A554 Gr 409/409L, A554 Gr 316, A554 Gr 202 stainless steel grades.

A554 Gr 409/409L Hollow Section

- Yield Strength: 170-310 MPa

- Tensile Strength: 380-560 MPa

- Elongation: 20% min

- Hardness (Rockwell B): 80-96

A554 Gr 316 Hollow Section

- Yield Strength: 205 MPa min

- Tensile Strength: 515 MPa min

- Elongation: 40% min

- Hardness (Brinell): 217 max

A554 Gr 202 Hollow Section

- Yield Strength: 260 MPa min

- Tensile Strength: 515 MPa min

- Elongation: 40% min

- Hardness (Rockwell B): 95 max