Incoloy 926 Alloy Steel Pipe, UNS N08926,W.Nr.1.4529, X1NiCrMoCu

April 19, 2024

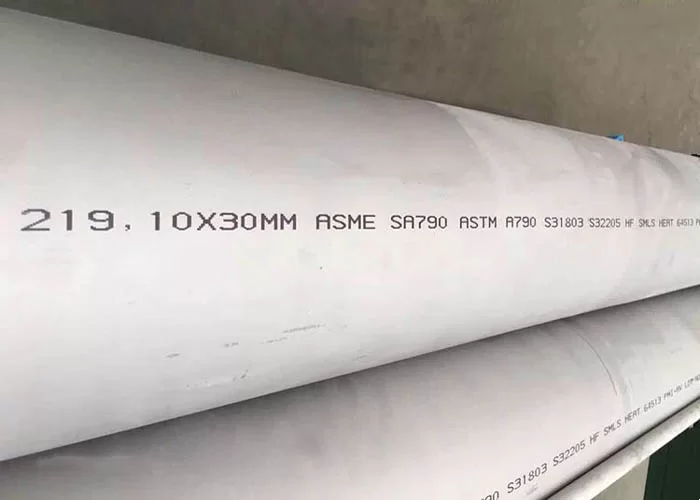

Duplex S32205 & UNS S31803 Stainless Steel Pipe

April 27, 2024ASTM A347/347H Stainless Steel Pipe

Alloy 347 stainless steel belongs to the family of austenitic stainless steels and is known for its exceptional stability due to the presence of stabilizing elements. This alloy is highly weldable, and in most cases, annealing is not necessary after welding unless stress relief is desired. The remarkable resistance to oxidation and corrosion exhibited by 347 stainless steel makes it a reliable choice for various applications. Its high creep strength allows it to perform optimally at temperatures up to 1600 °F.

ASTM A347/347H Stainless Steel Pipe:

ASTM A347/347H stainless steel pipe is a high-quality and reliable pipe that meets the standards set by the American Society for Testing and Materials (ASTM). It is specifically designed to offer excellent corrosion resistance and high-temperature strength, making it suitable for various industrial applications.

Stainless Steel 347 Seamless Pipe Material Specification:

The material specification for stainless steel 347 seamless pipes typically follows the ASTM A312/A312M standard. This standard specifies the requirements for seamless, welded, and heavily cold worked austenitic stainless steel pipes. The material specification includes details such as chemical composition, mechanical properties, dimensions, and tolerances.

Specifications

| Type | Sizes | Schedules | ASTM Standards |

|---|---|---|---|

| Bar | A276, A479 | ||

| Butt Weld Fittings | 1/2″ thru 12″ | Sch 10, 40, 80, 160 & XXH | A403 |

| Forgings | A182 | ||

| Pipe Welded & Seamless | 1/4″ thru 16″ | Sch 10, 40, 80, 160 & XXH | A312 |

| Tube, Welded | A249 | ||

| Tube, Seamless | A213 | ||

| Plate | A240 | ||

| Flange & Pressure Fittings | All Descriptions |

347H stainless steel pipe is mainly used where corrosion resistance and sustained operations at temperatures between 800°F and 1500°F (427°C ~ 816°C) is of the utmost importance. It is also a superior grade for use on heavy welded objects, which cannot be re-annealed.

Chemical production equipment

Boiler and heat exchanger

Oil and gas refinery piping

Radiant superheaters

High pressure steam pipes

Heavy wall-welded equipment

Aircraft exhaust stacks

Car manufacturing

347H stainless steel pipe is a high carbon austenitic stainless steel pipe, with an excellent heat-resistance material which is applied to boiler, heat exchanger, car and aircraft exhaust, chemical equipment etc. As a higher grade from AISI 321H, the intergranular corrosion of 347H is achieved through the use of niobium (Nb) as a stabilizing element to maximize this feature. SS 347 has a good mechanical properties welding performance, excellent resistance to intergranular corrosion .

Features of 347/347H Stainless Steel Pipe

Excellent resistance for high temperature

Similar resistance and corrosion protection as Alloy 321

Used for heavy welded equipment when annealing is not possible

Good oxidation resistance, on par with most other austenitic stainless steels

Chemical Material Composition of SS 347/347H Seamless Pipes:

The chemical composition of stainless steel 347/347H seamless pipes typically includes the following elements:

- Chromium (Cr): 17.0-20.0%

- Nickel (Ni): 9.0-13.0%

- Manganese (Mn): 2.0% max

- Silicon (Si): 0.75% max

- Carbon (C): 0.08% max

- Phosphorus (P): 0.045% max

- Sulfur (S): 0.030% max

- Columbium + Tantalum (Nb+Ta): 10xC-1.10% max

SS 347 Seamless Pipes Mechanical Properties:

The mechanical properties of stainless steel 347 seamless pipes are as follows:

- Tensile Strength: 515 MPa (minimum)

- Yield Strength: 205 MPa (minimum)

- Elongation: 40% (minimum)

- Hardness: 201 HB (maximum)

Equivalent Material of Stainless Steel 347 Pipes:

The equivalent materials for stainless steel 347 pipes are:

- AISI 347

- UNS S34700

- EN 1.4550

- JIS SUS 347

Ordering Information:

When ordering stainless steel 347 seamless pipes, it is important to provide the following information to the supplier:

- Quantity: Specify the required quantity of pipes.

- Size: Specify the nominal pipe size (NPS) or outside diameter (OD) and wall thickness.

- Length: Specify the desired length of the pipes.

- Grade: Specify the grade of stainless steel, in this case, 347 or 347H.

- Standards: Specify the applicable standards, such as ASTM A312/A312M.

- Additional Requirements: Specify any additional requirements, such as surface finish, testing, or packaging.

Stainless Steel Pipes ASTM A347/347H: The Ultimate Choice for Heat-Resistant Applications

When it comes to high-temperature applications, such as boilers, heat exchangers, car and aircraft exhaust systems, and chemical equipment, choosing the right material is crucial. That’s where ASTM A347/347H stainless steel pipes come into play. These pipes are made from a high carbon austenitic stainless steel, specifically designed to withstand extreme heat and provide exceptional performance in challenging environments.

What sets 347H stainless steel pipes apart from other stainless steel grades is their excellent heat-resistance properties. This is achieved through the addition of niobium (Nb) as a stabilizing element, which helps to prevent intergranular corrosion and enhance the overall performance of the material. As a higher grade compared to AISI 321H, 347H stainless steel pipes offer superior resistance to intergranular corrosion, making them an ideal choice for applications where exposure to corrosive environments is a concern.

Here are some key features and benefits of ASTM A347/347H stainless steel pipes:

- Heat Resistance: The primary advantage of 347H stainless steel pipes is their exceptional heat resistance. These pipes can withstand high temperatures without losing their structural integrity, making them suitable for applications in industries where heat is a critical factor. Whether it’s in boilers, heat exchangers, or exhaust systems, 347H stainless steel pipes can handle the heat with ease.

- Mechanical Properties: 347H stainless steel pipes exhibit excellent mechanical properties, including high tensile strength and good welding performance. This makes them easy to fabricate and install, ensuring reliable and secure connections in various piping systems.

- Corrosion Resistance: In addition to their heat resistance, 347H stainless steel pipes offer excellent resistance to intergranular corrosion. The addition of niobium as a stabilizing element helps to prevent the formation of chromium carbide precipitates, which can lead to intergranular corrosion. This makes 347H stainless steel pipes highly suitable for applications in corrosive environments, such as chemical processing plants.

- Versatility: ASTM A347/347H stainless steel pipes are versatile and can be used in a wide range of applications. From industrial equipment to automotive and aerospace components, these pipes provide the strength and durability required to withstand demanding conditions.

To ensure the highest quality and performance, it is essential to source ASTM A347/347H stainless steel pipes from reputable manufacturers and suppliers. This guarantees compliance with industry standards and ensures that the pipes meet the required specifications for your specific application.

In conclusion, ASTM A347/347H stainless steel pipes are the ultimate choice for heat-resistant applications. With their exceptional heat resistance, mechanical properties, and corrosion resistance, these pipes offer unmatched performance and reliability. Whether you’re in the chemical, automotive, or aerospace industry, choosing ASTM A347/347H stainless steel pipes ensures that your piping systems can withstand the heat and deliver optimal performance.

Alloy 347 stainless steel belongs to the family of austenitic stainless steels and is known for its exceptional stability due to the presence of stabilizing elements. This alloy is highly weldable, and in most cases, annealing is not necessary after welding unless stress relief is desired. The remarkable resistance to oxidation and corrosion exhibited by 347 stainless steel makes it a reliable choice for various applications. Its high creep strength allows it to perform optimally at temperatures up to 1600 °F.

One of the key characteristics of 347 stainless steel is the addition of columbium and tantalum. These elements play a crucial role in enhancing the properties of the alloy. Here are some of the desired characteristics imparted by columbium and tantalum:

- Prevents Harmful Carbide Precipitation in the Heat Affected Zone (HAZ) of the Weld Area: The presence of columbium and tantalum in 347 stainless steel prevents the formation of harmful carbides in the heat affected zone during welding. Carbide precipitation can lead to reduced corrosion resistance and compromised mechanical properties. By inhibiting carbide formation, columbium and tantalum ensure the structural integrity and longevity of the welded area.

- Imparts Substantial Immunity to Intergranular Corrosion: Intergranular corrosion is a common concern in stainless steel alloys, as it can lead to localized degradation and failure. However, the addition of columbium and tantalum in 347 stainless steel imparts significant immunity to intergranular corrosion. This ensures that the alloy can withstand corrosive environments without succumbing to localized damage.

- Reduces Embrittlement in the HAZ of the Weld Area: The heat affected zone (HAZ) of the weld area is susceptible to embrittlement, which can compromise the overall strength and durability of the welded joint. Fortunately, the presence of columbium and tantalum in 347 stainless steel helps reduce embrittlement in the HAZ. This ensures that the welded area maintains its toughness and integrity, even under challenging conditions.

FAQ

- What is the difference between ASTM A347 and ASTM A347H stainless steel pipes?

ASTM A347 stainless steel pipes are made from stainless steel grade 347, while ASTM A347H stainless steel pipes are made from a higher carbon version of grade 347, known as 347H. The addition of carbon provides improved high-temperature strength in 347H pipes. - What are the applications of ASTM A347/347H stainless steel pipes?

ASTM A347/347H stainless steel pipes are commonly used in industries such as chemical processing, oil and gas, power generation, and aerospace. They are suitable for applications in boilers, heat exchangers, exhaust systems, and other components that require heat resistance and corrosion resistance. - Can ASTM A347/347H stainless steel pipes be welded?

Yes, ASTM A347/347H stainless steel pipes have good weldability. They can be welded using common welding techniques, such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. It is important to follow proper welding procedures to ensure strong and reliable joints. - What is the chemical composition of ASTM A347/347H stainless steel pipes?

The chemical composition of ASTM A347/347H stainless steel pipes typically includes elements such as chromium, nickel, manganese, silicon, carbon, and niobium. The exact composition may vary depending on the specific manufacturer and grade. - Where can I purchase ASTM A347/347H stainless steel pipes?

ASTM A347/347H stainless steel pipes can be purchased from reputable manufacturers, suppliers, and distributors. It is recommended to source the pipes from trusted sources to ensure compliancewith industry standards and the desired quality. You can find a wide range of options by searching online or contacting local stainless steel pipe suppliers.