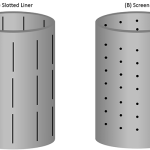

Slot liner , Slotted Liner Pipe

April 19, 2024

ASTM A347/347H Stainless Steel Pipe

April 23, 2024Incoloy 926 Alloy Steel Pipe: Unparalleled Corrosion Resistance and High Performance

As a leading supplier of Incoloy pipes, abtersteel takes pride in manufacturing and producing different sizes of Incoloy 926 welded pipes and tubes.. In this article, we will delve into the benefits and features of Incoloy 926 alloy steel pipes, including its specifications and applications.

Specifications of Incoloy 926 Alloy Steel Pipe:

UNS N08926: Incoloy 926 is designated as UNS N08926, which is a high-performance super-austenitic stainless steel. This designation ensures that the alloy meets specific chemical composition and mechanical property requirements, making it suitable for various applications.

W.Nr. 1.4529: Incoloy 926 is also known by its European standard designation, W.Nr. 1.4529. This number indicates the specific alloy composition and properties, ensuring consistency and compatibility in different regions.

Features of Incoloy 926 Welded Pipe & Tube:

The main features of Incoloy 926 (N08926) nickel-based alloy are as follows:

High Resistance to Pitting and Crevice Corrosion: Incoloy 926 demonstrates exceptional resistance to pitting and crevice corrosion in halide media and acidic media containing H2S.

Effective Resistance to Chloride Ion Stress Corrosion Cracking (SCC): This alloy effectively resists chloride ion stress corrosion cracking, making it suitable for practical applications.

Resistance to Various Corrosions: Incoloy 926 exhibits resistance to various corrosive environments, including oxidation and reduction conditions.

Enhanced Mechanical Performance: Compared to Cronifer 1925 LC-Alloy 904L, Incoloy 926 offers improved mechanical performance.

Improved Metallurgical Stability: Incoloy 926 demonstrates enhanced metallurgical stability when compared to Ni18 alloys.

Certified for Pressure Vessel Manufacturing: Incoloy 926 is certified for pressure vessel manufacturing, meeting the VdTUV-196 ~ 400 °C and ASME certification requirements.

Superior Corrosion Resistance: Incoloy 926 welded pipes and tubes are specifically designed to withstand corrosive environments. The alloy’s high nickel and chromium contents, combined with the addition of 6% molybdenum and nitrogen, provide excellent resistance to a wide range of corrosive media, including acids, chlorides, and seawater.

High Strength and Durability: Incoloy 926 welded pipes and tubes exhibit high strength and durability, making them suitable for applications where reliability is crucial. The alloy’s composition and metallurgical structure contribute to its exceptional mechanical properties, allowing it to withstand high-pressure and high-temperature conditions.

Advanced Manufacturing Techniques: abtersteel ensures the highest quality standards by carefully selecting raw materials from reputable suppliers. The Incoloy 926 strip or plate used to form the welded pipes and tubes undergoes a rigorous quality control process. The most advanced splitting and welding technology is employed to manufacture each Incoloy 926 welded pipe and tube, ensuring precision and consistency.

Solution Annealing Capability: For applications that require higher demands, abtersteel offers solution annealed Incoloy 926 welded pipes and tubes. Solution annealing involves heating the pipes or tubes to a specific temperature and holding them at that temperature to achieve a uniform microstructure. This process enhances the alloy’s mechanical properties and corrosion resistance.

| ASTM / AISI | DIN | JIS | GB |

|---|---|---|---|

| Incoloy 926 | 1.4529 | / | / |

| Heat Treatment Temperature |

σb (Mpa) | σs (Mpa) | δ% | HB | HRB | HV |

|---|---|---|---|---|---|---|

| °C | ≥ | ≥ | ≥ | ≤ | ≤ | ≤ |

| 1150-1200 | 650 | 295 | 35 | / | / | / |

Physical Properties

| Density | g/cm3 | 8.03 | |

|---|---|---|---|

| lb/in.3 | 0.29 | ||

| Melting Range | °F | 2410 – 2550 | |

| °C | 1320 – 1400 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) |

Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell B, max | |

| Solution Annealed | 650 | 295 | 35 | … | … |

*Mechanical Properties According to ASTM B673 & ASTM B674*

General mechanical and physical properties of 1.4529, X1NiCrMoCuN25-20-7 grade

- Tensile strength, Rm: 650 – 850 MPa

- Yield point, RP0,2: >300 MPa

- Elongation, A > 40%

- Modulus of elasticity, E: 195 GPA

- Hardness: <250 HB

- Heat capacity, cp20℃: 450 J * kg-1 * K-1

- Heat conductivity, λ: 12 W * m-1 * K-1

Applications of Incoloy 926

A1: Incoloy 926 exhibits high resistance to pitting and crevice corrosion in halide media and acidic media containing H2S. It is also resistant to chloride ion stress corrosion cracking (SCC) and various corrosive environments in both oxidizing and reducing conditions.Q2: What are the mechanical properties of Incoloy 926 (N08926)?

A2: Incoloy 926 offers slightly better mechanical properties compared to Cronifer 1925 LC-Alloy 904L. It has enhanced metallurgical stability and is certified for pressure vessel manufacturing.Q3: What are the applications of Incoloy 926 (N08926)?

A3: Incoloy 926 finds applications in various industries, including reverse osmosis seawater desalination, pulp and paper industry, chemical processing, firefighting and seawater purification systems, marine engineering, acid gas production, flue gas desulfurization systems, phosphoric acid production, sulfuric acid separation and condensation, power plant cooling-water pipe systems, corrosive chemical transportation, organic production equipment, and more.

Q4: Is Incoloy 926 suitable for high-temperature applications?

A4: Yes, Incoloy 926 is designed to maintain excellent corrosion resistance in high-temperature environments. It can be used in temperatures ranging from -196°C to 400°C.

Q5: How does Incoloy 926 compare to other nickel-based alloys?

A5: Incoloy 926 offers comparable or even superior corrosion resistance to materials like Hastelloy and titanium. It exhibits better heat resistance than typical chrome-nickel stainless steels and has oxidation resistance equivalent to higher-grade alloys used at temperatures up to 1900 degrees Fahrenheit (1038 °C).