Pipe-Based Sand Control Screen: A Comprehensive Solution for Effective Filtration

April 15, 2024

Incoloy 926 Alloy Steel Pipe, UNS N08926,W.Nr.1.4529, X1NiCrMoCu

April 19, 2024Slotted Liner Pipe: Enhancing Sand Control Efficiency in Horizontal Completions

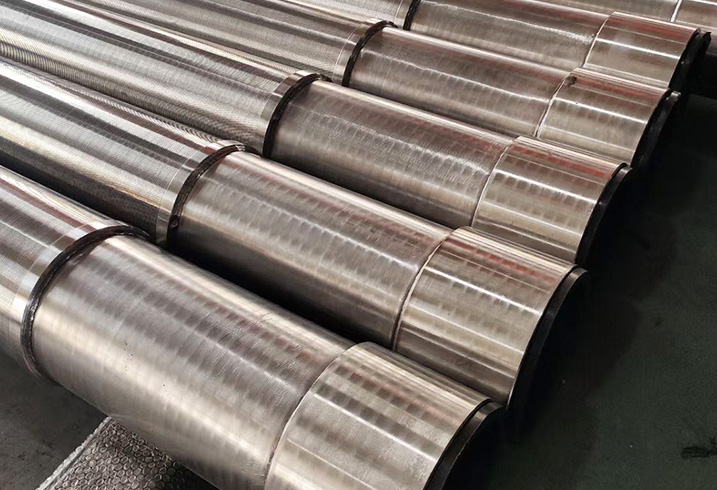

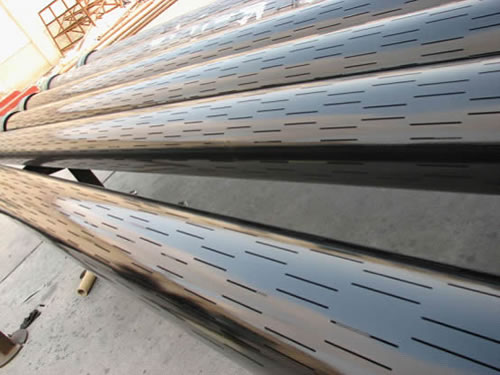

Slotted liner pipes, also known as standalone screens, are widely used in long horizontal completions and low productivity wells to improve sand control efficiency. These precision-engineered screens are manufactured using advanced CNC controlled slotting machines or laser machines. Each slot is meticulously deburred, cleaned, and drift tested to meet the stringent standards set by the American Petroleum Institute (API). Slotted liner pipes are available in various sizes, with customizable slot sizes, slot shapes, and slot spacing to cater to the specific sand control requirements of each well.

Introduction to Slotted Liner Pipes

Slotted liner pipes are designed to prevent the influx of sand and other particulate matter while allowing for the smooth flow of fluids. They consist of a base pipe, which conforms to API casing or tubing specifications, with precision slots cut along its length. These slots are strategically placed to maximize sand control efficiency while maintaining optimal flow rates. Slotted liner pipes are commonly used in horizontal completions and wells with low productivity, where sand production poses a significant challenge.

Key Features of Slotted Liner Pipes

- API Base Pipe with Customized Slot Size:

- Slotted liner pipes are manufactured using API base pipes, ensuring compliance with industry standards. The slot size can be customized to suit the specific sand control requirements of each well. This customization allows for efficient sand control while maintaining the desired flow rates.

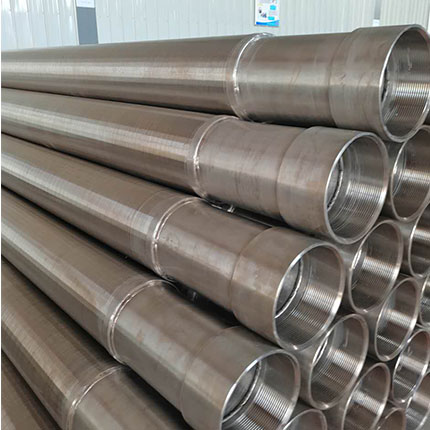

- Length and Outside Diameter:

- Slotted liner pipes are available in various lengths, with a maximum length of 15m (each). The outside diameter ranges from 2 3/8″ to 20″ (60.3mm-508mm). This flexibility in length and diameter ensures compatibility with different wellbore dimensions and operational needs.

- Slot Number and Shapes:

- The number of slots in a slotted liner pipe can be tailored to meet the specific sand control requirements of each well. The slots can be arranged in different patterns, including straight in line, staggered, or spiral patterns. The choice of slot shape and pattern depends on factors such as sand characteristics, well conditions, and desired flow rates.

- Slot Space:

- The spacing between slots in a slotted liner pipe can be customized to optimize sand control efficiency. The slot space is determined based on the size of sand particles and the desired flow rates. By adjusting the slot space, operators can achieve the desired balance between sand control and fluid flow.

Applications of Slotted Liner Pipes

Slotted liner pipes find applications in various scenarios where sand control is crucial. Some common applications include:

- Long Horizontal Completions:

- Slotted liner pipes are extensively used in long horizontal completions, where sand production can be significant. They help prevent sand influx and maintain the productivity of the well.

- Low Productivity Wells:

- Slotted liner pipes are employed in low productivity wells, where sand control is essential to optimize production rates. They effectively filter out sand and prevent its entry into the wellbore.

- High Sand Production Zones:

- Slotted liner pipes are utilized in wells with high sand production zones. By strategically placing the slots in these zones, operators can control sand production and prolong the life of the well.

- Geothermal Wells:

- Slotted liner pipes are used in geothermal wells to prevent sand ingress and ensure the efficient operation of the geothermal system. They help maintain the integrity of the well and protect downhole equipment.

Advantages of Slotted Liner Pipes

Slotted liner pipes offer several advantages over other sand control methods:

- Enhanced Sand Control Efficiency:

- The precision-engineered slots in slotted liner pipes effectively filter out sand and prevent its entry into the wellbore. This enhances sand control efficiency and reduces the risk of sand production-related issues.

- Customizable Design:

- Slotted liner pipes can be customized in terms of slot size, slot number, slot shapes, and slot spacing. This allows for tailored solutions to meet the specific sand control requirements of each well.

- Compatibility with Different Well Conditions:

- Slotted liner pipes are compatible with a wide range of well conditions, including long horizontal completions, low productivity wells, and high sand production zones. Their versatility makes them a reliable choice for various applications.

- High-Quality Manufacturing:

- Slotted liner pipes are manufactured using advanced CNC controlled slotting machines or laser machines. This ensures precise slot dimensions, deburred edges, and thorough cleaning, meeting the stringent standards set by API.

- Longevity and Durability:

- Slotted liner pipes, made from high-quality materials and manufactured with precision, offer excellent durability and longevity. They can withstand the harsh downhole conditions and provide long-term sand control solutions.

Slot Size: Customizable to Meet Customer’s Requirements

The slot size of slotted liner pipes, including slot width and length, can be customized to suit the specific needs of customers. This customization allows for optimal sand control and fluid flow in different well conditions. The minimum slot width for straight or keystone slots is 0.012 inch, while the maximum slot width can reach up to 0.25 inch.

Here are some examples of slot sizes:

- Straight Slots:

- 1.5 inch long, 0.012 inch wide

- 2.0 to 2.5 inch long, 0.024 inch wide

- 2.5 inch long, 0.078 inch wide

- 2.5 inch long, 0.015 inch wide

- 2.5 inch long, 0.025 inch wide

- 2.5 inch long, 0.125 inch wide

- 2.5 inch long, 0.016 inch wide

- 2.5 inch long, 0.038 inch wide

- 2.5 inch long, 0.250 inch wide

- 2.5 inch long, 0.018 inch wide

- 2.5 inch long, 0.048 inch wide

- 2.5 inch long, 0.058 inch wide

Please note that these are just examples, and the slot size can be further customized based on specific requirements.

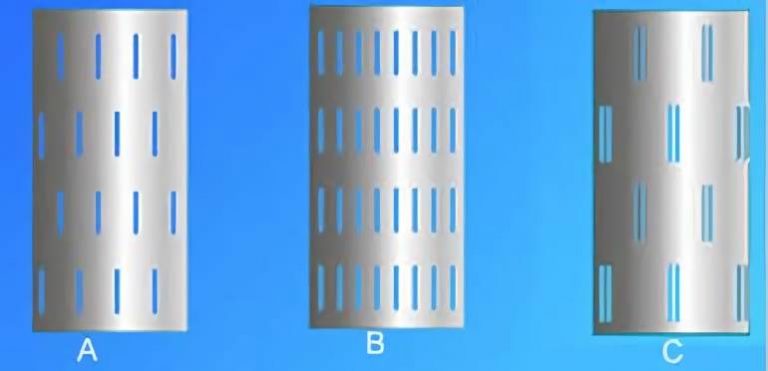

Slotting Pattern: Three Types of Arrangement

There are three types of slotted liner pipe arrangements, each with its own advantages and applications:

A. Single Staggered Slots (Type A):

- This arrangement features slots that are staggered in a single row. The edge of the slit is perpendicular, and the cut edge is smooth without any burrs. The slots are evenly distributed along the length of the pipe. This arrangement is commonly used in sand control applications.

B. Straight Slots (Type B):

- Straight slots have straight sides with equal width through the wall of the casing. This arrangement is typically used in consolidated formations or when slots of 0.030″ or wider are specified. Straight slots offer higher resistance to wear and are more economical than keystone slots. However, there is a higher possibility of clogging compared to keystone slots.

C. Multiple Staggered Slots (Type C):

- Multiple staggered slots refer to slots that are staggered in multiple rows. This arrangement provides increased open area for sand control and improved work efficiency. The slots are evenly distributed and offer effective sand control while maintaining optimal fluid flow.

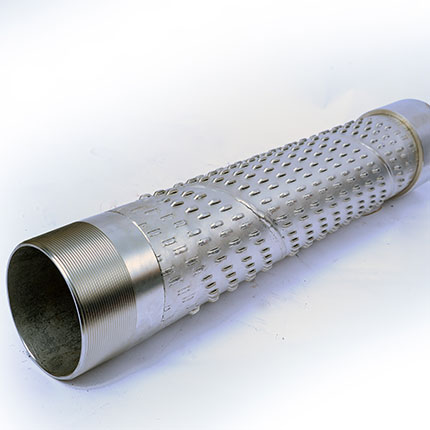

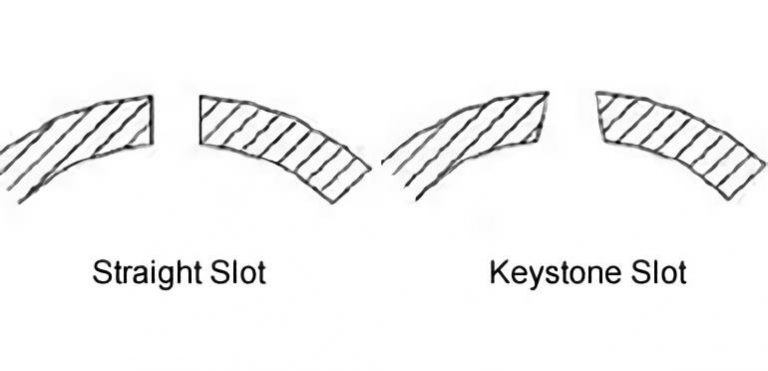

Slot Shape: Straight Slot vs. Keystone Slot

Slotted liner pipes can be manufactured with two different slot shapes: straight slots and keystone slots. Each slot shape has its own advantages and considerations:

Straight Slot:

- Straight slots have straight sides with equal width through the wall of the casing. They are commonly used in consolidated formations or when slots of 0.030″ or wider are specified. Straight slots offer higher resistance to wear and are more economical than keystone slots. However, there is a higher possibility of clogging compared to keystone slots.

Keystone Slot:

- Keystone slots are shaped like a reversed “V,” with narrower spacing at the liner surface and wider spacing in the inside casing wall. This shape allows for sand grains to bridge across the opening, ensuring that all particles that enter the hole will completely pass through the wall. Keystone slots substantially reduce the possibility of clogging and improve work efficiency. However, they may be slightly more expensive than straight slotted liners.

Both straight slots and keystone slots have their own advantages and considerations, and the choice between them depends on the specific sand control requirements and operational needs of the well.

In conclusion, slotted liner pipes offer customizable slot sizes, slotting patterns, and slot shapes to meet the specific sand control requirements of each well. Whether it’s a single staggered slot, straight slot, or multiple staggered slots, the precision-engineered slots in slotted liner pipes enhance sand control efficiency and ensure optimal fluid flow. The choice of slot shape, whether straight or keystone, depends on factors such as wear resistance, clogging possibility, and cost considerations.

Slot density

Slot density refers to the number of slots per foot of pipe. It is determined by the open area of the pipe’s outer surface. Open area is an important factor of reducing the sand control capacity of a slotted liner. Generally speaking, open area ranges from 2% to 4%.

When the open area, the slot width and the diameter of the liner are determined, the slot density per foot can be calculated by the following formula:

| N = | 12πD C |

| 100 W L |

N stands for slot density or the number of slots per foot

D stands for outside diameter of the liner in inch

C stands for open area, percentage

W stands for slot width in inch

L stand for the length of slot in inch

Example: For a 4.5” slotted liner, its open area is 3%, the slot width is 0.02 inch, the slot length is 1.5’, so what is the number of slot per foot?

According to the formula above, the required Number of slots is shown below:

| N = | 12×π×4.5×3 | = 172 |

| 100×0.020×1.5 |

Note: This formula is just a conventional calculation for either straight slot or seamed keystone slot.

Frequently Asked Questions (FAQ)

1. What is the purposeof using slotted liner pipes in sand control?

Slotted liner pipes are used in sand control to prevent the influx of sand and other particulate matter into the wellbore while allowing for the smooth flow of fluids. They help maintain optimal production rates by filtering out sand and protecting downhole equipment from damage.

2. How are slotted liner pipes manufactured?

Slotted liner pipes are manufactured using advanced CNC controlled slotting machines or laser machines. These machines ensure precise slot dimensions, deburred edges, and thorough cleaning of the slots. The base pipe used for slotted liners conforms to API casing or tubing specifications.

3. Can the slot size and slot spacing be customized?

Yes, the slot size and slot spacing of slotted liner pipes can be customized to meet the specific sand control requirements of each well. This customization allows for efficient sand control while maintaining the desired flow rates.

4. In what applications are slotted liner pipes commonly used?

Slotted liner pipes find applications in long horizontal completions, low productivity wells, high sand production zones, and geothermal wells. They are used in scenarios where sand control is crucial to optimize production rates and protect downhole equipment.

5. What are the advantages of using slotted liner pipes?

Some advantages of using slotted liner pipes include enhanced sand control efficiency, customizable design options, compatibility with different well conditions, high-quality manufacturing, and longevity. Slotted liner pipes offer reliable and durable solutions for sand control in various applications.

Conclusion

Slotted liner pipes play a vital role in enhancing sand control efficiency in long horizontal completions and low productivity wells. Their customizable design, compatibility with different well conditions, and high-quality manufacturing make them a preferred choice for sand control applications. By effectively filtering out sand and preventing its entry into the wellbore, slotted liner pipes help maintain optimal production rates and protect downhole equipment. With their durability and longevity, slotted liner pipes provide long-term sand control solutions for the oil and gas industry.