SS304L Oil Well Screen Sand Control Pipes

March 25, 2024

V-Shaped Slot Water Well Screens

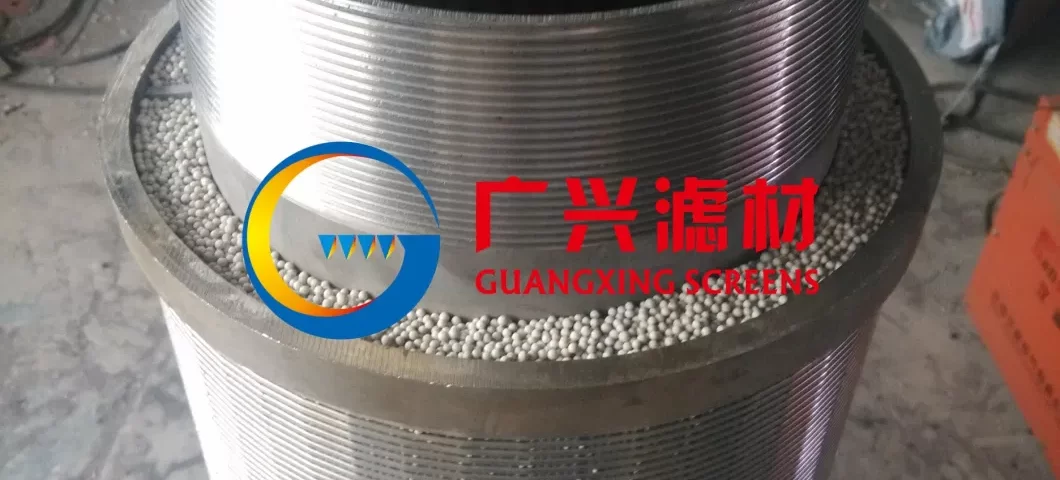

March 28, 2024The use of prepacked well screens in construction, particularly in groundwater monitoring and extraction systems, is crucial for ensuring the safety and efficiency of various applications like drinking water supply, environmental monitoring, and industrial processes. Here are key points from the search results to guide a 3500-word exploration of this topic:

Purpose and Function: Prepack well screens facilitate the safe extraction or monitoring of groundwater by providing consistent filtration to prevent the entry of sediments and contaminants while allowing water flow. They help maintain water quality, prevent clogging, and reduce the potential for biofouling within wells

1

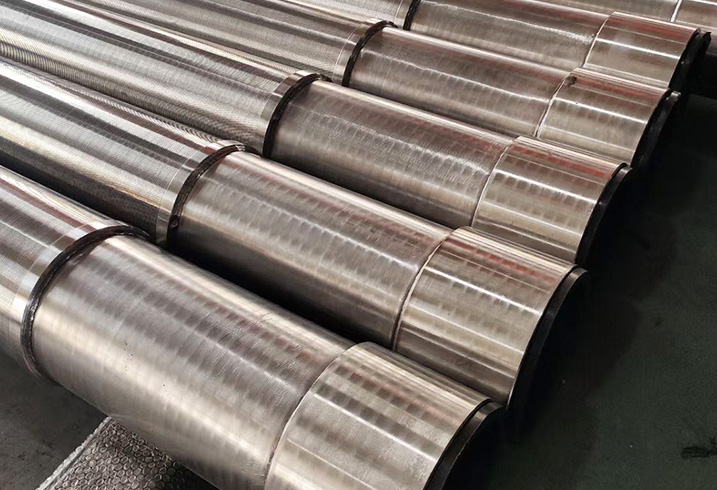

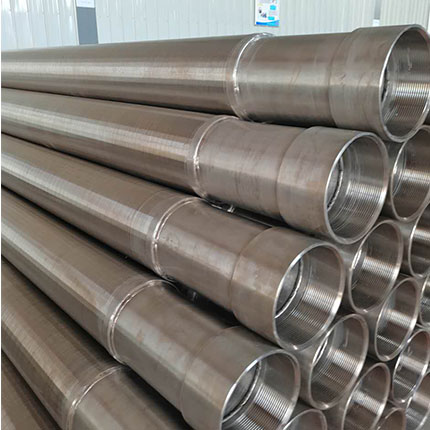

stainless steel sand filter / 7″ stainless steel pre-pack screens /Pipe based screen can be manufactured using stainless steel grades or API 5CT carbon steel casing.

Johnson Screens uses prime pipe, thoroughly cleaned and de-burred after perforating.

Diameters for pipe based screens range from in. 1.5 in. / 38 mm to 18 in. / 457 mm.

| Base pipe | Screen jacket | |||||||||

| Nominal diameter (in) |

Outside diameter (mm) |

Weight(1b/ft) Wall thickness (mm) |

Hole diameter (in) |

Hole Density |

Hole area (in2/ft) |

OD of screen Jacket (in) |

Open area (in2/ft) |

Slot (in) |

||

| 0.008″ | 0.012″ | 0.015″ | 0.020″ | |||||||

| 2-3/8 | 60 | 4.6(4.83) | 3/8 | 96 | 10.60 | 2.86 | 12.68 | 17.96 | 21.56 | 26.95 |

| 2-7/8 | 73 | 6.4(5.51) | 3/8 | 108 | 11.93 | 3.38 | 14.99 | 21.23 | 25.48 | 31.85 |

| 3-1/2 | 88.9 | 9.2(6.45) | 1/2 | 108 | 21.21 | 4.06 | 18.00 | 25.50 | 30.61 | 38.26 |

| 4 | 101.6 | 9.5(5.74) | 1/2 | 120 | 23.56 | 4.55 | 20.18 | 28.58 | 34.30 | 42.88 |

| 4-1/2 | 114.3 | 11.6(6.35) | 1/2 | 144 | 28.27 | 5.08 | 15.63 | 22.53 | 27.35 | 34.82 |

| 5 | 127 | 13(6.43) | 1/2 | 156 | 30.63 | 5.62 | 17.29 | 24.92 | 30.26 | 38.52 |

| 5-1/2 | 139.7 | 15.5(6.99) | 1/2 | 168 | 32.99 | 6.08 | 18.71 | 26.96 | 32.74 | 41.67 |

| 6-5/8 | 168.3 | 24(8.94) | 1/2 | 180 | 35.34 | 7.12 | 21.91 | 31.57 | 38.34 | 48.80 |

| 7 | 117.8 | 23(8.05) | 5/8 | 136 | 42.16 | 7.58 | 23.32 | 33.61 | 40.82 | 51.95 |

| 7-5/8 | 194 | 26.4(8.33) | 5/8 | 148 | 45.88 | 8.20 | 25.23 | 36.36 | 44.16 | 56.20 |

| 8-5/8 | 219 | 32(8.94) | 5/8 | 168 | 51.08 | 9.24 | 28.43 | 40.98 | 49.76 | 63.33 |

| 9-5/8 | 244.5 | 36(8.94) | 5/8 | 188 | 58.28 | 10.18 | 31.32 | 45.15 | 54.82 | 69.77 |

| 10-3/4 | 273 | 45.5(10.16) | 5/8 | 209 | 64.79 | 11.36 | 34.95 | 50.38 | 61.18 | 77.86 |

| 13-3/8 | 339.7 | 54.5(9.65) | 5/8 | 260 | 80.60 | 14.04 | 37.80 | 54.93 | 66.87 | 85.17 |

.

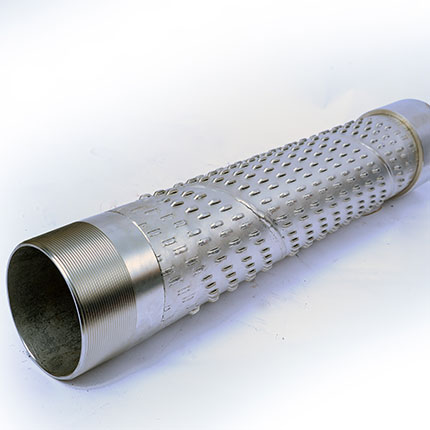

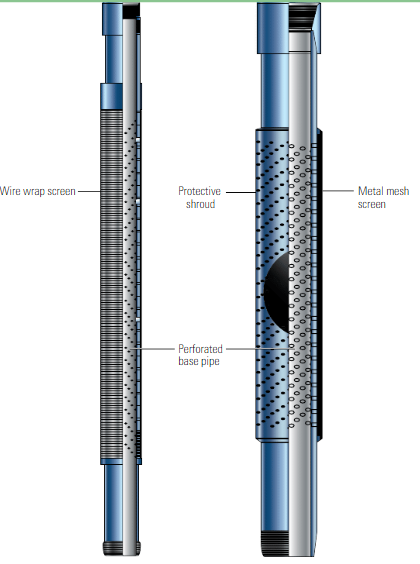

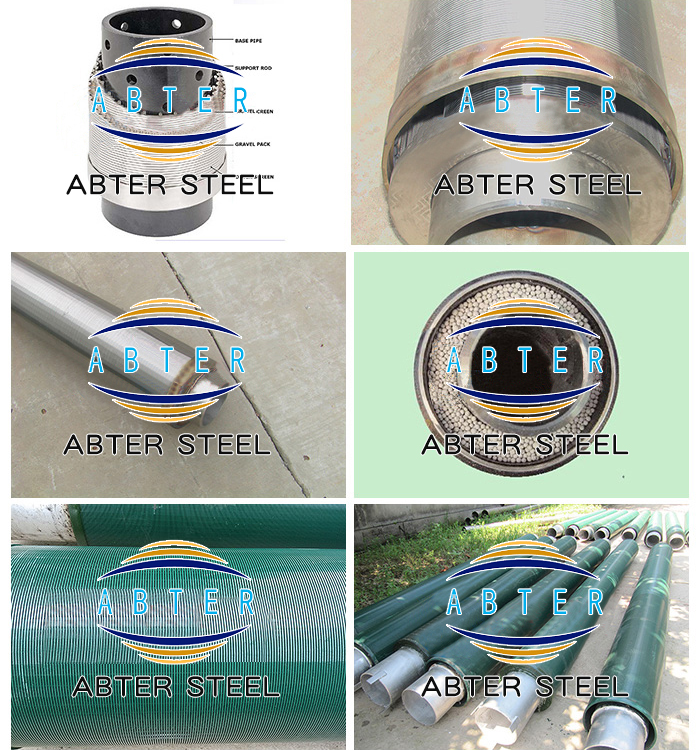

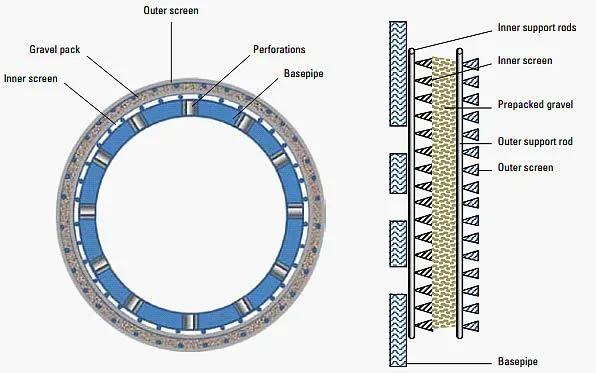

Types of Prepacked Screens: There are different types of prepacked screens available, such as wire-wrapped pre-packed screens used in well-sorted sand or stand-alone completions. These screens contain perforated base pipes, inner and outer screen jackets, and graded sand between the jackets to act as a filter for reservoir particles

3

.

Sand Control Solutions: Prepacked sand screens offer an alternative to conventional gravel packing in wells where gravel packing is not feasible or economical. They provide sand control integrity by offering extra protection against erosional forces and voids during production

2

.

Customization and Material: Prepacked screens can be customized based on specific requirements, including gravel sizes, sand coating, pack thickness, material grades for the screen and pipe (e.g., stainless steel 304, 316L), and end fittings tailored to API tubing or casing standards

3

.

Specialized Screen Technologies: Specialty well screens like abtersteel™, guangxing®, metal-mesh screens offer tailored solutions for sand control conditions in various completions to improve tool longevity, production rates, flow area, and minimize pressure buildup

4

.

This comprehensive exploration can delve into the technical aspects, benefits, applications, customization options, and advancements in prepacked well screens used in construction to safeguard workers and enhance resilience in groundwater monitoring and extraction systems.

how does a sand control prepacked well screen work

A sand control prepacked well screen works by providing a filtration medium that prevents impurities, such as sand and rocks, from entering a wellbore. Here is how it functions based on the search results:

Purpose: Sand control is crucial in the oil and gas industry to prevent impurities from entering the wellbore, ensuring the quality of extracted oil and preventing equipment damage. Sand control screens, including prepacked screens, act as filters to retain impurities within the reservoir

1

.

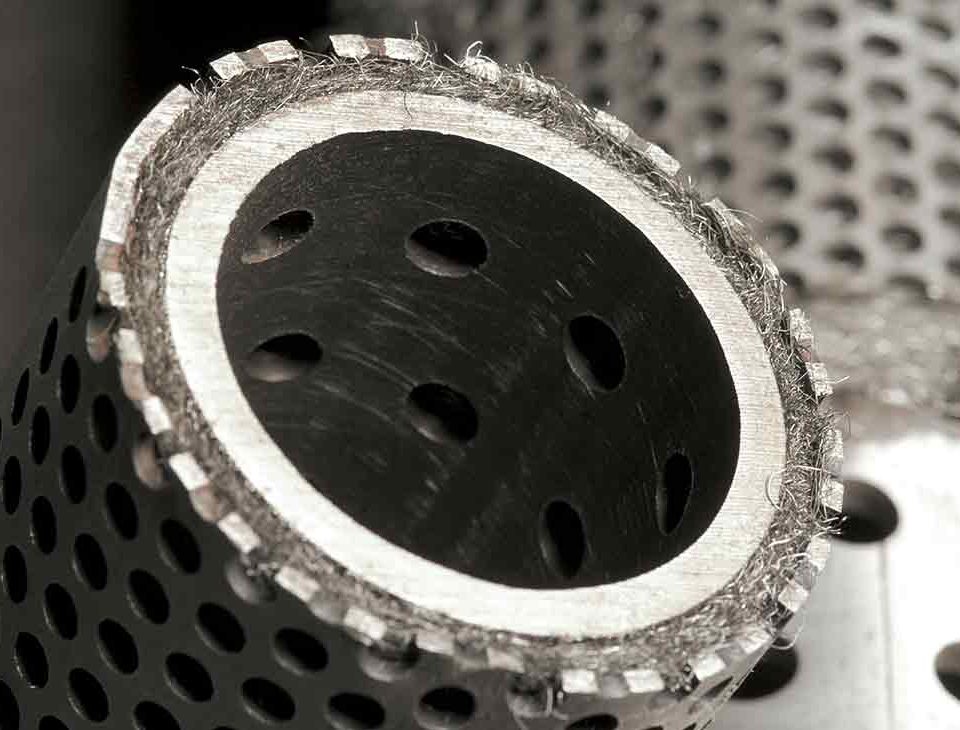

Formation: Prepacked screens use a keystone slot wire filter similar to wire-wrapped screens but with the unique feature of gravel between the screens. This gravel layer acts as a filter to prevent sand from entering the wellbore while allowing fluid flow

2

.

Functionality: Once sand packs around the prepacked screen, they act as a filtration media that prevents sand from flowing into the wellbore. This process helps maintain sand control integrity by providing additional protection against erosional forces and voids during production

2

.

Benefits: Prepacked screens offer a cost-effective alternative to conventional gravel packing when gravel packing is not feasible or economical. They provide added erosion protection and ensure sand control integrity in wells where traditional methods may not be suitable

2

.

In summary, a sand control prepacked well screen functions by using a layer of gravel between screens to filter out impurities like sand and rocks, ensuring efficient production and protecting the wellbore from damage in various industries, particularly in oil and gas extraction.

what are the common materials used in sand control prepacked well screens

Common materials used in sand control prepacked well screens include:

Stainless Steel: Stainless steel is a common material used in prepacked screens due to its durability, corrosion resistance, and strength. It ensures the longevity and effectiveness of the screens in various well conditions

2

.

Gravel: Gravel is often used as a filtration medium in prepacked screens to prevent sand and other impurities from entering the wellbore. It acts as a filter layer between the screens to maintain sand control integrity

3

.

Resin-Coated Gravel: Resin-coated gravel is utilized in prepacked screens to enhance sand control. The resin-coated gravel is consolidated around the screen, providing additional protection against erosional forces and voids during production

3

.

Metal Mesh: Metal mesh screens are another material used in prepacked screens to provide reliable and long-lasting sand control. They offer a greater flow area for hydrocarbons, increasing production rates while effectively controlling sand

4

.

These materials are carefully selected based on their properties to ensure efficient sand control, longevity, and optimal performance of prepacked well screens in various applications within the oil and gas industry.