Differences Between Steel Pipe Varnish Coating, Zinc Coating, and Epoxy Coating

March 18, 2024

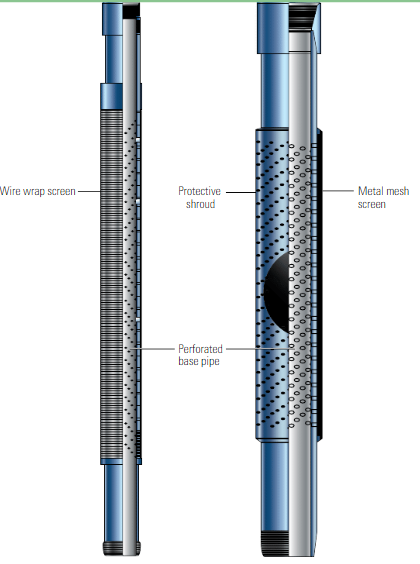

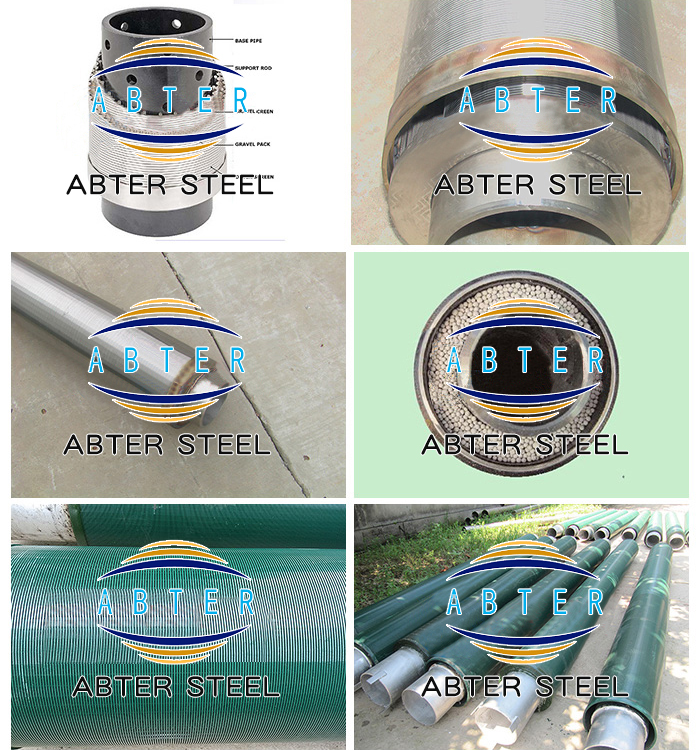

Sand Control Prepacked Well Screen

March 25, 2024

Leveraging SS304L Materials for Superior Sand Control and Productivity in Oil Well Screen Pipes

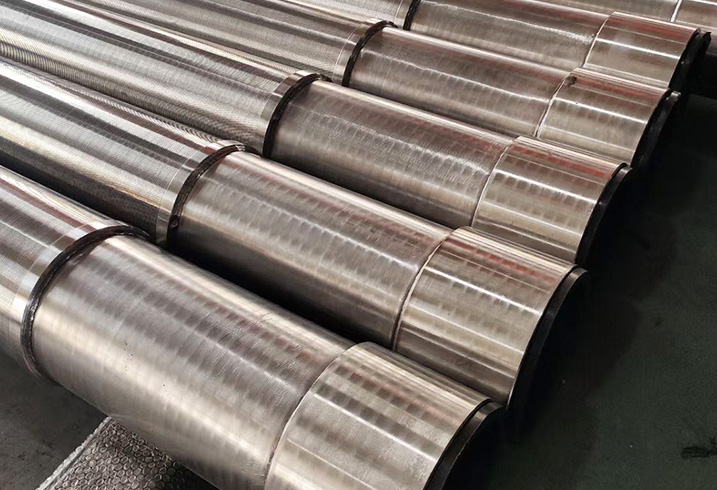

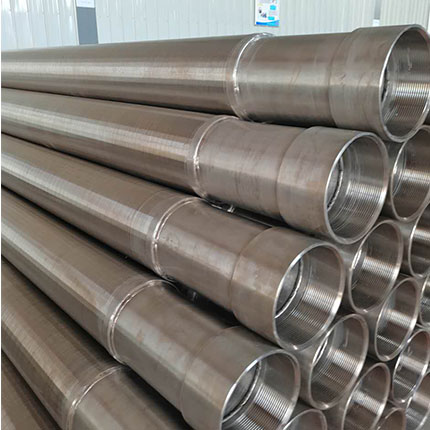

When drilling and completing oil wells, one of the most critical downhole components is the production screen responsible for controlling sand influx while maximizing reservoir fluid recovery. Stainless steel screen pipes utilizing SS304L alloy offers distinct advantages over conventional screen materials through its resistance to corrosion and long-term strength.

In this article, we’ll explore how the chromium-nickel stainless formulation of SS304L benefits oil well screen performance. We’ll cover the material properties that enhance sand resistance, evaluate mesh designs suited for various reservoir applications, and provide tips on determining projects best served by an SS304L screen pipe solution.

SS304L: A Superior Sand Control Alloy

As one of the most widely used austenitic stainless steels, SS304L exhibits key characteristics making it well-suited for oilfield screen pipes including:

- Corrosion resistance – High chromium content protects against water, H2S, and downhole acids/bases over the long-run.

- Strength retention – SS304L maintains strength after years of production pressure cycling where carbon steels experience fatigue.

- Mesh durability – Harder and more rupture-resistant than screen meshes like plastic or composite under abrasive sand conditions.

These inherent material properties help SS304L based screen pipes withstand hostile, sand-laden reservoir fluids while maintaining permeability far better than alternatives.

| Base Pipe | Screen Jacket | |||||||||

| Nominal Diameter(in) | Outside Diameter(mm) | Weight lb/ft

Wall Thickness(mm) |

Hole diameter in | Hole Density | Hole ApreaIn2/ft | OD of Screen Jacket(in)

|

Open area

In2/ft Slot |

|||

| 0.008” | 0.012” | 0.015” | 0.020” | |||||||

| 2-3/8 | 60 | 4.6(4.83) | 3/8 | 96 | 10.60 | 2.86 | 12.68 | 17.96 | 21.56 | 26.95 |

| 2-7/8 | 73 | 6.4(5.51) | 3/8 | 108 | 11.93 | 3.38 | 14.99 | 21.23 | 25.48 | 31.85 |

| 3-1/2 | 88.9 | 9.2(6.45) | 1/2 | 108 | 21.21 | 4.06 | 18.00 | 25.50 | 30.61 | 38.26 |

| 4 | 101.6 | 9.5(5.74) | 1/2 | 120 | 23.56 | 4.55 | 20.18 | 28.58 | 34.30 | 42.88 |

| 4-1/2 | 114.3 | 11.6(6.35) | 1/2 | 144 | 28.27 | 5.08 | 15.63 | 22.53 | 27.35 | 34.82 |

| 5 | 127 | 13(6.43) | 1/2 | 156 | 30.63 | 5.62 | 17.29 | 24.92 | 30.26 | 38.52 |

| 5-1/2 | 139.7 | 15.5(6.99) | 1/2 | 168 | 32.99 | 6.08 | 18.71 | 26.96 | 32.74 | 41.67 |

| 6-5/8 | 168.3 | 24(8.94) | 1/2 | 180 | 35.34 | 7.12 | 21.91 | 31.57 | 38.34 | 48.80 |

| 7 | 177.8 | 23(8.05) | 5/8 | 136 | 42.16 | 7.58 | 23.32 | 33.61 | 40.82 | 51.95 |

| 7-5/8 | 194 | 26.4(8.33) | 5/8 | 148 | 45.88 | 8.20 | 25.23 | 36.36 | 44.16 | 56.20 |

| 8-5/8 | 219 | 32(8.94) | 5/8 | 168 | 51.08 | 9.24 | 28.43 | 40.98 | 49.76 | 63.33 |

| 9-5/8 | 244.5 | 36(8.94) | 5/8 | 188 | 58.28 | 10.18 | 31.32 | 45.15 | 54.82 | 69.77 |

| 10-3/4 | 273 | 45.5(10.16) | 5/8 | 209 | 64.79 | 11.36 | 34.95 | 50.38 | 61.18 | 77.86 |

| 13-3/8 | 339.7 | 54.5(9.65) | 5/8 | 260 | 80.60 | 14.04 | 37.80 | 54.93 | 66.87 | 85.17 |

The above data is for reference only, actual information is subject to the drawings

Leveraging Mesh Design

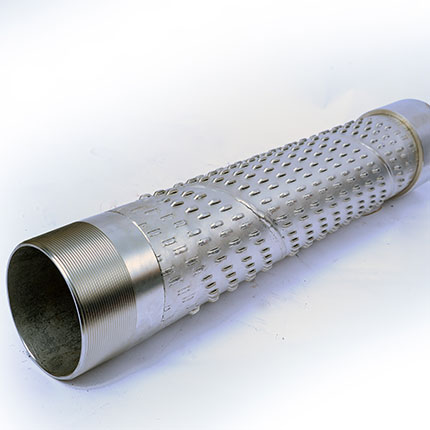

In addition to corrosion resistance, modern expanded mesh geometries optimize SS304L screen pipe performance including:

- Small, consistent openings – Tightly controlled mesh apertures between 50-300 microns address a wide range of sand sizes.

- High open area – Expanded patterns provide over 70% open flow area for maximum fluid collection.

- Self-supporting mesh – Free spans avoid settlement issues of other meshes under sediment loading.

- Bonded mesh – Firm attachment to pipe body resists separating from shocks and vibration during installation/production.

Properly selecting the mesh geometry based on reservoir factors allows SS304L pipes to provide long-term sand control tailored for each producer’s specific needs.

Determining Project Fit

SS304L based screen pipes are ideal for reservoirs with:

- Aggressive production fluids (H2S, CO2, etc.)

- High sediment levels requiring maximum strength/durability

- Long-term flow assurance critical to project economics

- Field life spanning 10-30+ years

Engaging screen experts experienced in materials selection and mesh design optimizes the solution. Upfront modeling of fluid-rock interactions and downhole conditions ensures SS304L delivers on its inherent durability and uptime advantages through the life of oilfield assets.

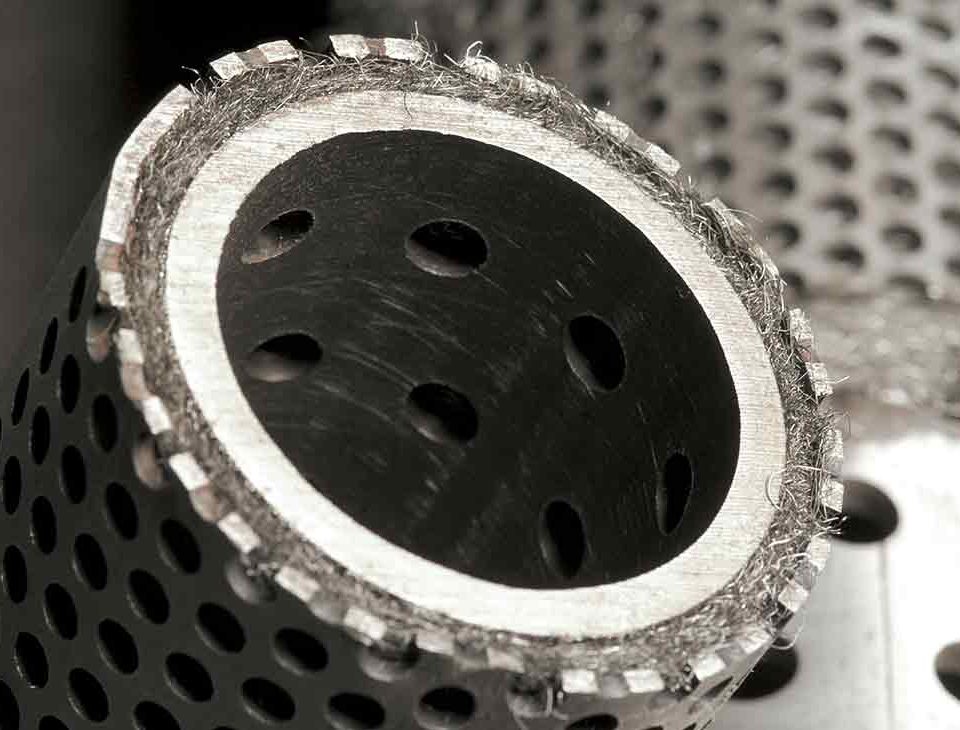

Image Suggestion: A close-up photomicrograph showing the expanded mesh geometry of an SS304L screen pipe sample at 100x magnification.

Image Alt Text: Microscopic image of the mesh patterns in a stainless steel SS304L oil well screen pipe sample, with individual apertures and the expanded structure visible.