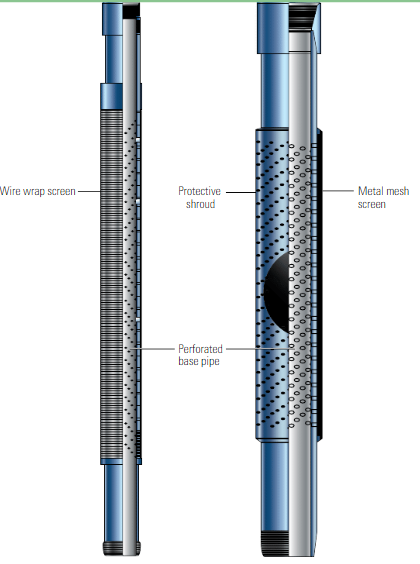

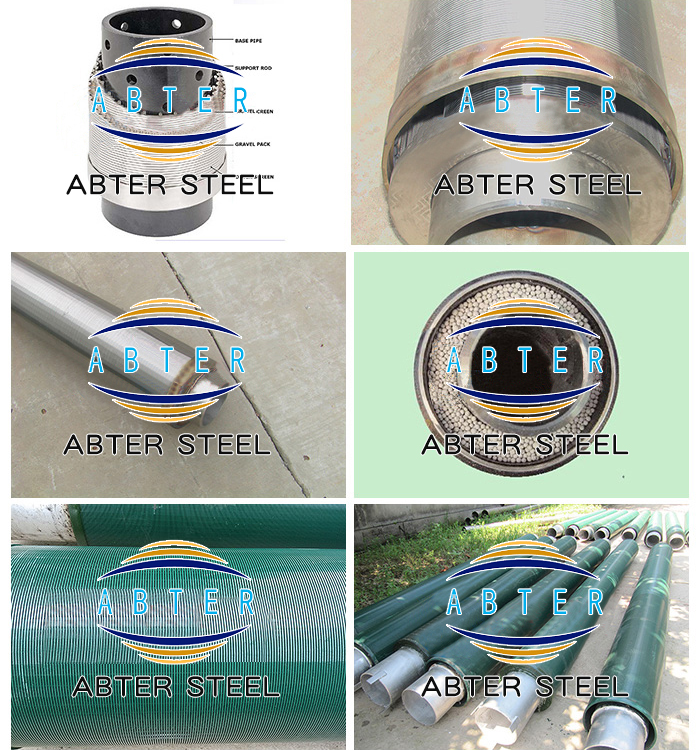

Sand Control Prepacked Well Screen

March 25, 2024

Monel 404 UNS N04404 Alloy steel pipe | DIN W. Nr. 2.4867

March 31, 2024Maximizing Intake and Control With V-Shaped Slot Water Well Screens

For agricultural, community, or industrial water wells extracting from unconsolidated aquifers, an optimized well development and design is key to achieving high productivity goals over the long term. V-wedge shaped slot screens address common issues faced with traditional designs through their innovative intake geometry and gravel packing mechanisms.

In this post, we’ll explore the advantages V-slot screens provide through:

- Enhanced hydraulic compatibility with surrounding strata

- Improved particle entrapment within the gravel envelope

- Self-jetting installation processes for reduced costs

We’ll also provide practical insights on subsurface conditions where V-slot screens deliver strongest results and indicate how pre-development planning lends to overall project success.

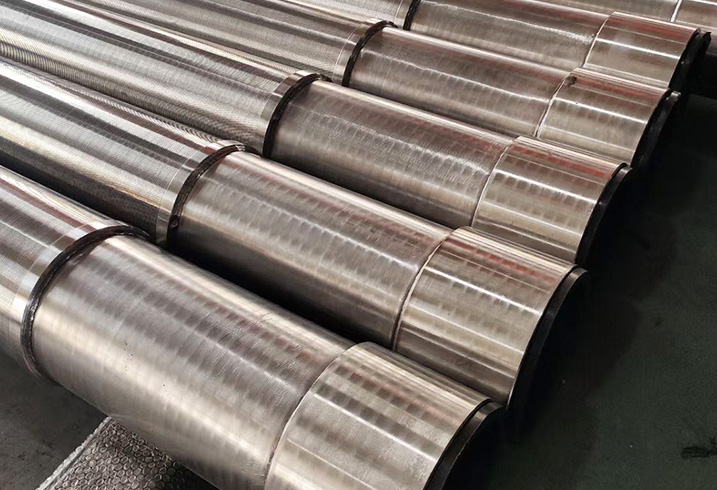

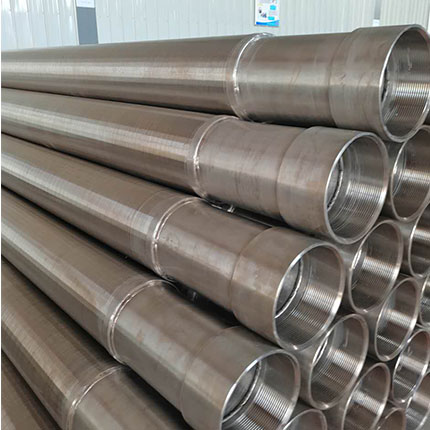

Specifications of Water Well Continuous Slot Screen

|

material |

304,304H,321,316L,Carbon steel

|

| wire size |

0.75×1.5mm, 1×2mm, 2X3mm, 2.3×3mm, 3×5mm |

| diameter |

25mm, 33mm, 37mm, 40mm, 60mm, 177mm,219mm,273mm,323mm |

| width(mm) |

1.50 1.80 2.30 3.00 3.30 3.70 |

| end connection | welding (beveled end), thread coupling(STC,LTC,BTC) or flange or sealed |

| surface treatment | galvanized, painted, polish, packiled and passivation, etc. |

| note | wires, rods and slot sizes can be customized |

Maximizing Hydraulic Continuity

Water well screens rely on hydraulic connectivity between well openings and the native formation to efficiently intake groundwater. Standard slot designs impair this through:

- Improper wetted perimeter matching aquifer pore sizes

- Formation skin damage during development/surging

V-shapes mitigate these issues by their:

- Adjustable 60-135 degree wedge apertures conforming to various geologies

- Gentler inclines lessening stress on friable strata during installation

Hydraulic modeling confirms V-slots induce minimal “drawdown” at the wellbore compared to conventional options.

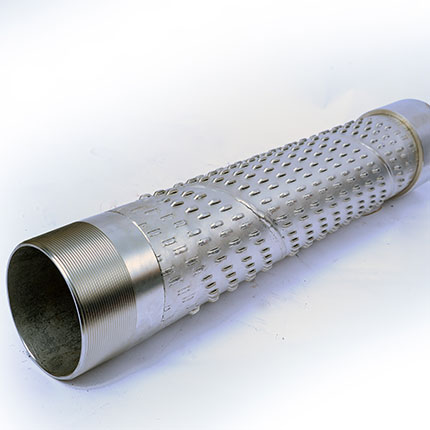

Superior Sand Control

A textbook gravel envelope forms the basis for long-term well performance, safeguarding screen openings without inhibiting inflows. V-slots enable:

- Self-packing gravel tendencies maintain an optimal 6-12″ thickness

- Wedge tip causes settling particles to adhere instead of dropping down-hole

- Stable gravel column resists settlement under pumping stress

This leads to minimal clogging over decades versus traditional screens requiring frequent re-development.

Maximized Success Through Planning

By understanding aquifer geology, water quality analysis and intended well yield objectives ahead of specification, V-slot operators can count on continual high production rates. Integrating subsurface expertise into the design mitigates costlier future repairs from improper screening.

Providing a customized, optimized solution forms the foundation for maximum return on investment and long-term supply assurance of this critical natural resource.

Title: Maximizing Intake and Control With V-Shaped Slot Water Well Screens

Focus Keyword: V wedge shaped water well slot screens

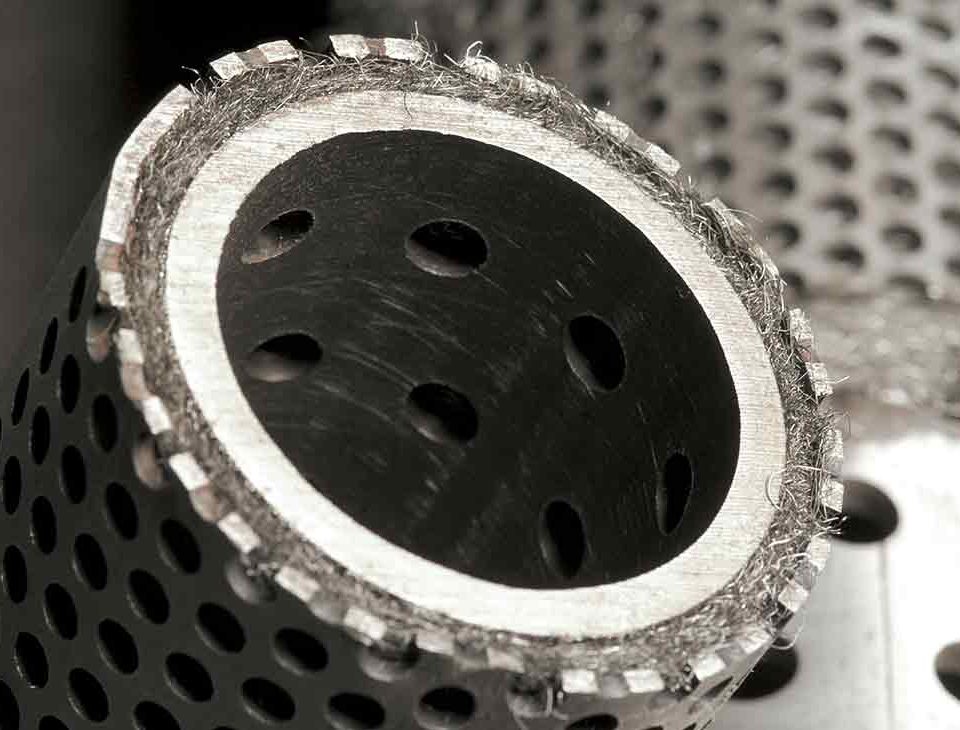

Image Suggestion: An illustration depicting the 60-135 degree V-shaped openings on a water well screen sample alongside an enlarged cross-section showing the wedge geometry and gravel envelope.

Image Alt Text: Diagram of a V-wedge slotted water well screen showing the angled slot apertures and expanded cross-section with gravel pack.