EN 10217 Pipes Special Considerations for Installation and Maintenance

June 10, 2024

ASTM A249 Stainless Steel Boiler Tube

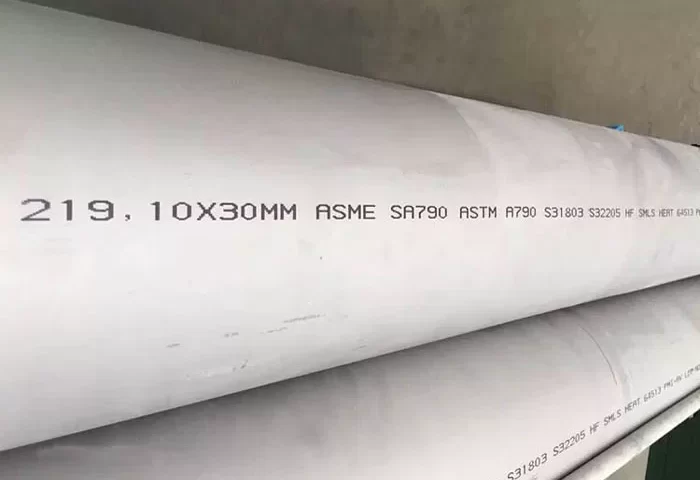

June 22, 2024ASME SA790 Duplex Steel Pipe

ASME SA790 covers seamless and welded duplex stainless steel pipe for general corrosive service, with particular emphasis on resistance to stress corrosion cracking. This specification includes various grades of duplex stainless steels, which are known for their excellent mechanical properties and high corrosion resistance.

Key Features

- Material: Duplex stainless steel (e.g., UNS S31803, S32205)

- Forms: Seamless and welded

- Applications: General corrosive service, particularly in environments prone to stress corrosion cracking

Duplex Steel Pipe & Tubes Specifications

| Specification | Details |

|---|---|

| Standard | ASME SA790 / ASTM A790 |

| Grades | UNS S31803, UNS S32205, and other duplex grades |

| Outer Diameter | 6 mm to 610 mm (varies based on specific requirements) |

| Wall Thickness | 0.5 mm to 40 mm (SCH10 to SCH160, XXS) |

| Length | Single random, double random, or as specified |

| Manufacturing | Seamless, Welded (ERW, EFW) |

Duplex Steel Pipe Price List

Prices can vary based on market conditions, grade, size, and supplier. Below is a general price range:

| Product | Price (USD per meter) |

|---|---|

| Duplex Seamless Pipe | $30 – $100 |

| Duplex Welded Pipe (ERW) | $20 – $60 |

| Duplex Welded Pipe (EFW) | $25 – $80 |

Note: Prices are indicative and can vary significantly based on the specific grade, size, and supplier.

Duplex Steel Tube Size Chart

| Nominal Pipe Size (NPS) | Outer Diameter (OD) | Wall Thickness (SCH10) | Wall Thickness (SCH40) | Wall Thickness (SCH80) |

|---|---|---|---|---|

| 1/2″ | 21.34 mm | 2.11 mm | 2.77 mm | 3.73 mm |

| 1″ | 33.40 mm | 2.77 mm | 3.38 mm | 4.55 mm |

| 2″ | 60.33 mm | 2.77 mm | 3.91 mm | 5.54 mm |

| 4″ | 114.30 mm | 3.05 mm | 6.02 mm | 8.56 mm |

| 6″ | 168.28 mm | 3.40 mm | 7.11 mm | 10.97 mm |

Duplex Steel Pipe Weight Chart

| Nominal Pipe Size (NPS) | Outer Diameter (OD) | Wall Thickness (SCH40) | Weight (kg/m) |

|---|---|---|---|

| 1/2″ | 21.34 mm | 2.77 mm | 1.27 kg/m |

| 1″ | 33.40 mm | 3.38 mm | 2.68 kg/m |

| 2″ | 60.33 mm | 3.91 mm | 5.94 kg/m |

| 4″ | 114.30 mm | 6.02 mm | 16.07 kg/m |

| 6″ | 168.28 mm | 7.11 mm | 28.26 kg/m |

Duplex Steel Pipe Pressure Rating

Pressure ratings for duplex steel pipes depend on the specific grade and wall thickness. Below are typical pressure ratings for common sizes:

| Nominal Pipe Size (NPS) | Wall Thickness (SCH40) | Pressure Rating (psi) |

|---|---|---|

| 1/2″ | 2.77 mm | 3,200 psi |

| 1″ | 3.38 mm | 2,600 psi |

| 2″ | 3.91 mm | 2,300 psi |

| 4″ | 6.02 mm | 2,000 psi |

| 6″ | 7.11 mm | 1,700 psi |

Note: These values are indicative and can vary based on the specific grade and temperature conditions.

ASME SA790 / ASTM A790 UNS S31803, UNS S32205 Duplex Stainless Steel Pipe

ASME SA790 / ASTM A790 specifies seamless and welded duplex stainless steel pipes for general corrosive service, particularly where resistance to stress corrosion cracking is essential. Duplex stainless steels, such as UNS S31803 and UNS S32205, provide a combination of excellent mechanical properties and high corrosion resistance.

Key Features

- Base Material: Duplex stainless steel, which has a mixed microstructure of austenite and ferrite, typically in a 50/50 ratio.

- Grades: UNS S31803 and UNS S32205

- Forms: Seamless and welded pipes

- Applications: Suitable for use in environments with high chloride content and where stress corrosion cracking can be an issue.

Chemical Composition

| Element | UNS S31803 (%) | UNS S32205 (%) |

|---|---|---|

| Carbon (C) | ≤ 0.030 | ≤ 0.030 |

| Manganese (Mn) | ≤ 2.00 | ≤ 2.00 |

| Phosphorus (P) | ≤ 0.030 | ≤ 0.030 |

| Sulfur (S) | ≤ 0.020 | ≤ 0.020 |

| Silicon (Si) | ≤ 1.00 | ≤ 1.00 |

| Chromium (Cr) | 21.0 – 23.0 | 22.0 – 23.0 |

| Nickel (Ni) | 4.50 – 6.50 | 4.50 – 6.50 |

| Molybdenum (Mo) | 2.50 – 3.50 | 3.00 – 3.50 |

| Nitrogen (N) | 0.08 – 0.20 | 0.14 – 0.20 |

Mechanical Properties

| Property | UNS S31803 | UNS S32205 |

|---|---|---|

| Tensile Strength (min) | 620 MPa (90 ksi) | 655 MPa (95 ksi) |

| Yield Strength (min) | 450 MPa (65 ksi) | 450 MPa (65 ksi) |

| Elongation (min) | 25% | 25% |

| Hardness (max) | 290 HBW | 290 HBW |

Typical Applications

- Oil and Gas Industry: Used in pipelines, flowlines, and risers for transporting crude oil, natural gas, and produced water in offshore and onshore environments.

- Chemical Processing: Transporting aggressive chemicals and handling high-temperature fluids.

- Petrochemical Plants: Suitable for environments with high chloride content and where resistance to stress corrosion cracking is required.

- Power Generation: Used in power plants for steam lines and other high-temperature applications.

- Desalination Plants: High resistance to seawater makes it suitable for seawater desalination equipment.

Manufacturing Process

- Material Selection: High-quality duplex stainless steel billets or slabs are chosen.

- Forming: The material is hot-worked to form the initial pipe shape.

- Cold Working (for seamless pipes): The pipe is cold-drawn to achieve the desired dimensions and mechanical properties.

- Welding (for welded pipes): The pipe is formed and welded using methods such as ERW (Electric Resistance Welding) or EFW (Electric Fusion Welding).

- Heat Treatment: Pipes undergo solution annealing to dissolve any precipitates and ensure a uniform microstructure.

- Pickling and Passivation: The pipe surface is treated to remove any scale, enhance corrosion resistance, and ensure a clean finish.

- Testing: Pipes are subjected to various tests, including hydrostatic, nondestructive, and mechanical tests to ensure compliance with specifications.

Testing and Quality Assurance

- Hydrostatic Testing: Ensures that the pipe can withstand the required pressure without leaking.

- Nondestructive Testing (NDT): Includes ultrasonic testing, radiographic testing, and eddy current testing to detect any defects.

- Mechanical Testing: Tensile tests, hardness tests, and impact tests to verify mechanical properties.

- Corrosion Testing: Ensures the pipe’s resistance to pitting, crevice corrosion, and stress corrosion cracking.

Conclusion

Duplex stainless steel pipes, particularly UNS S31803 and UNS S32205, are well-suited for demanding applications requiring high strength and excellent corrosion resistance. They are widely used in industries such as oil and gas, petrochemicals, and power generation, where they provide