Ductile Iron Water Pipe Systems Examination : Construction, Installation, and Properties

November 9, 2023

Pipe Fittings Manufacturing Processes

November 16, 2023ALTERNATIVE MATERIALS (JIS, BS, DIN) FOR ASTM SPECIFICATIONS

TABLE OF CONTENTS

- Scope

- Basis

- Additional Requirements

- Table 1: Plates

- Table 2: Pipes

- Table 3: Tubes

- Table 4: Forging

- Table 5: Castings

- Table 6: Bolts and Nuts

- Table 7: Bars and Shapes

- Table 8: Piping Fittings

- Table 9: Nonferrous Materials

1. SCOPE

This document provides a list of alternative materials from the Japanese Standard (JIS, JPI), British Standard (BS), and Deutshe Industrie Normen (DIN) that can serve as substitutes for ASTM Specifications. These alternatives apply to commonly used materials such as plates, pipes, tubes, forgings, castings, bolts and nuts, bars and shapes, piping fittings, and nonferrous materials.

2. BASIS

The proposed substitute materials are not exact matches for the ASTM Specifications. However, they match in alloy content and tend to exhibit similar or greater ultimate tensile strength. Exceptions to this equivalence are highlighted.

3. ADDITIONAL REQUIREMENTS

Aspects of the ASTM Specifications that are not encapsulated by the substitute specifications are listed in the respective tables, with additional clarification provided in footnotes in Section

SUBSTITUTE MATERIAL (JIS, BS, DIN ) FOR ASTM SPECIFICATION

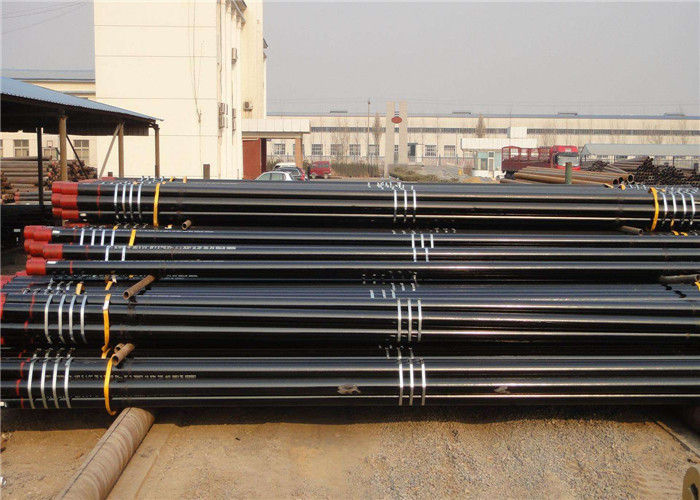

abter steel stands as a comprehensive supplier of seamless steel pipes, providing both wholesale and retail solutions from a range of domestic and international manufacturers.

The manufacturing process of these pipes adheres strictly to several standards, including EN 10208-2, EN 10208-1, EN-10216, DIN 1629, DIN1630, DIN 17120, DIN17175, DIN 2391, API Spec 5L, ASTM A53/A106, and PN-80/H-74219.

Seamless steel pipes from abter feature an outer diameter ranging from 21.3 mm to 508.0 mm. These pipes are delivered with either straight or bevelled end faces. Before delivery, each pipe undergoes a stringent tightness test and a non-destructive automatic ultrasound and/or radiological test, the latter only at the customer’s discretion. These pipes are available in lengths from a minimum of 4 metres to a maximum of 13 metres.

The material used in these pipes is either unalloyed or low-alloy standard steel, quality steel, or special steel, depending on the necessary mechanical and technical properties and the specific application. By default, pipes are delivered in black, without a protective coating. However, external three-layer polyethylene coating via extrusion moulding, and internal epoxy coating for pipes with a diameter over 168 mm, can be applied based on customer requirements.

For pipes necessitating a different form of anticorrosive protection, such as galvanisation, arrangements must be made in advance.

| Standard | Outer diameter |

Thickness | Length | Steel grade |

| (mm) | (mm) | (m) | ||

| PN-80/H-74219 | 21,3 – 273,0 | 2,0 – 10,0 | 4,0 – 12,0 | R35; R45;18G2A |

| DIN 2448/1629 DIN 2448/1630 |

31,8 – 508,0 | 2,6 – 50,0 | 4,0 – 14,0 | St. 37.0 – St 37.4 St. 44.0 – St 44.4 St. 52.0 – St 52.4 |

| EN 10208-2 | 21,3 – 508,0 | 2,0 – 25 | 8 –18 | L245 NB L290 NB L360 NB L415 NB |

| EN-10216-1 EN-10216-2 EN-10216-3 EN-10216-4 |

21,3 – 406.4 | 2,0 – 25 | 6 – 14 | P195 TR1/TR2; P235 TR1/TR2; P265 TR1/TR2 P195GH; P235GH; P265GH; 16Mo3 P275 NL/NL2; P355 N/NH; P355 NL1/NL2 P215NL; P255QL; P265NL |

| ASTM A64/A106 | 13,7 – 508,0 | 2,28 – 23,8 | 5,0 – 12,5 | A; B |

| API 5L | 219,1 – 508,0 | 7,9 – 23,8 | 5,0 – 12,5 | B; X42; X46; X52; X60; X65 |

abter.: Producer of High-Frequency Welded Steel Pipes

abter. manufactures high-frequency welded steel pipes that comply with numerous standards, including EN 10208-2, EN 10208-1, DIN 1626, DIN 17120, API Spec 5L, EN-10217, PN-H-74221, and PN-79/H-74244.

These high-frequency welded pipes from abter. have an outer diameter ranging from 114.3 mm to 508.0 mm. Available with either straight or bevelled end faces, the pipes are subjected to a rigorous tightness test and a non-destructive automatic ultrasound and/or radiological test — the latter upon customer’s request — before delivery. The pipes come in lengths spanning from a minimum of 6 metres to a maximum of 18 metres.

The materials used in the pipes include unalloyed or low-alloy standard steel, quality steel, or special steel, determined by the necessary mechanical and technical characteristics and the intended application. By default, the pipes are supplied in black, without a protective coating. However, customer-specific requirements can lead to the application of an external three-layer polyethylene coating by extrusion moulding, and an internal epoxy or cement coating.

For alternative anticorrosion protections, such as galvanisation, arrangements need to be made in advance.

| Standard | Strength class or steel grade | |||||||

| API Spec 5L | B | X42 | X46 | X52 | X56 | X60 | X65 | X70 |

| ASTM A53 | B | |||||||

| DIN 1626 | St 37.0 | St 44.0 | St 52.0 | |||||

| EN 10208-1 | L235GA L245GA |

L290GA | L360GA | |||||

| EN 10208-2 | L245 NB/MB |

L290 NB/MB |

L360 NB/MB |

L415 NB/MB |

L450 NB/MB |

L485 NB/MB |

||

| PN-79/H-74244 | G235 | G295 | G355 | G390 | ||||

| PN-H-74221 | L245 | L290 | L360 | |||||

Length ranges from 6 to 18 metres.

| Diameter | Wall thickness | ||||||||||||||||

| mm | 2,6 | 2,9 | 3,2 | 3,6 | 4,0 | 4,5 | 5,0 | 5,6 | 6,3 | 7,1 | 8,0 | 8,8 | 10,0 | 11,0 | 12,5 | 14,2 | 16,0 |

| 114,3 | X | X | X | X | X | X | X | X | X | X | X | X | X | ||||

| 159,0 | X | X | X | X | X | X | X | X | X | X | X | X | X | ||||

| 168,3 | X | X | X | X | X | X | X | X | X | X | X | X | X | ||||

| 219,1 | X | X | X | X | X | X | X | X | X | X | X | X | |||||

| 270,0 | X | X | X | X | X | X | X | X | X | X | X | X | |||||

| 323,9 | X | X | X | X | X | X | X | X | X | X | X | X | |||||

| 406,4 | X | X | X | X | X | X | X | X | X | X | X | ||||||

| 508,0 | X | X | X | X | X | X | X | X | X | ||||||||

Manufacturing pipes of wall thickness values outside of the abovementioned range requires earlier arrangements.

| maks. X 50 | maks. X 60 | maks. X 70 | ||||||

-steel-pipe.jpg)