September 5, 2015

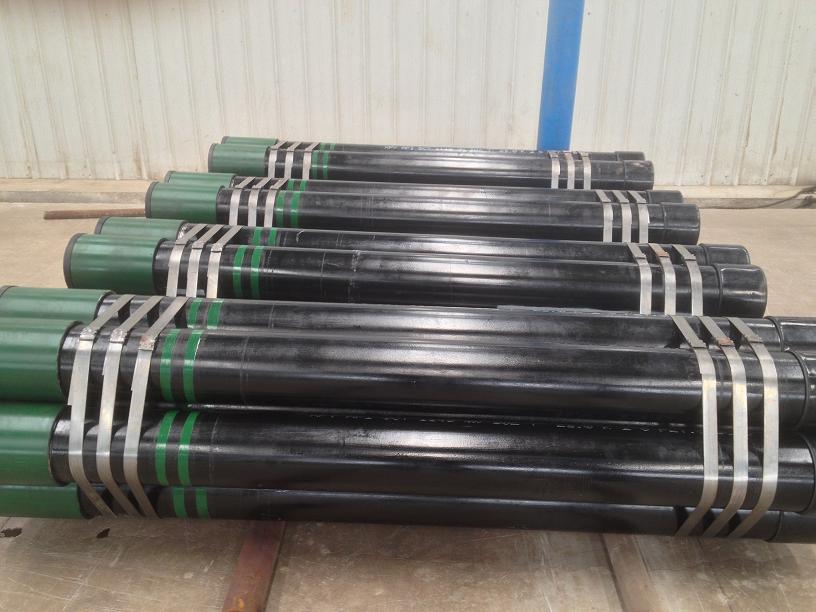

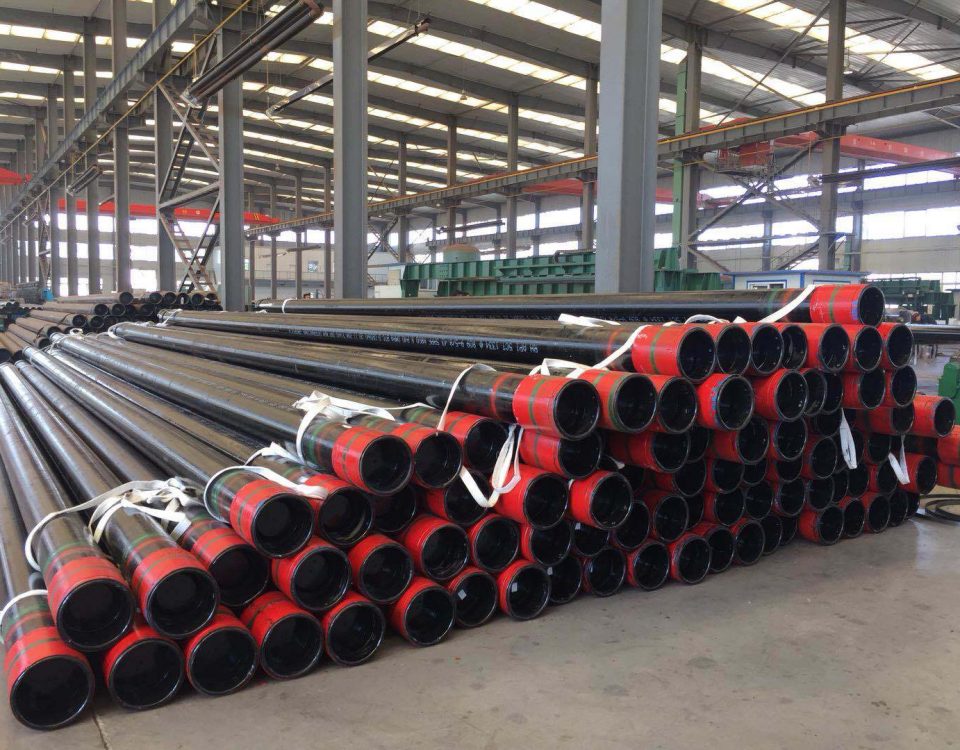

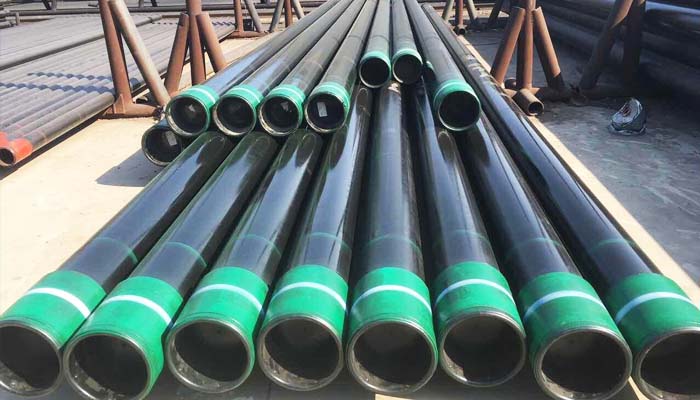

Hot sale carbon steel pipe/tube API 5L for natural gas and oil using 1. Grade:API 5L GR.B,A106 GR.B,A53 GR.B,A179, 2. Size: 1/4″ -24inch seamless, 24″-48″ weled 3. Standard: API 5L,ASTM A53,ASTM A106,ASTM A179,BS1387 4. Certification: ISO9001, SGS,API,BV,PED,MILL CERTIFICATE 5 chemical compositions of the API-5L stee pipes Standard Steel Grade […]