API 5ct Tubing: Tubings are used as pipe to transport crude oil or natural gas from layer of the oil to surface, can bear better pressure during oil or gas production, and have smaller diameters.

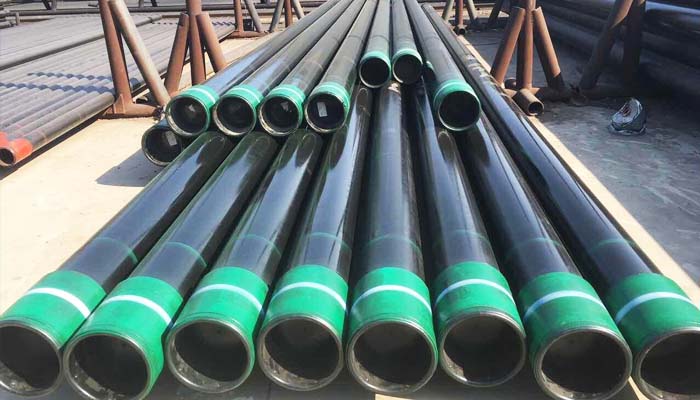

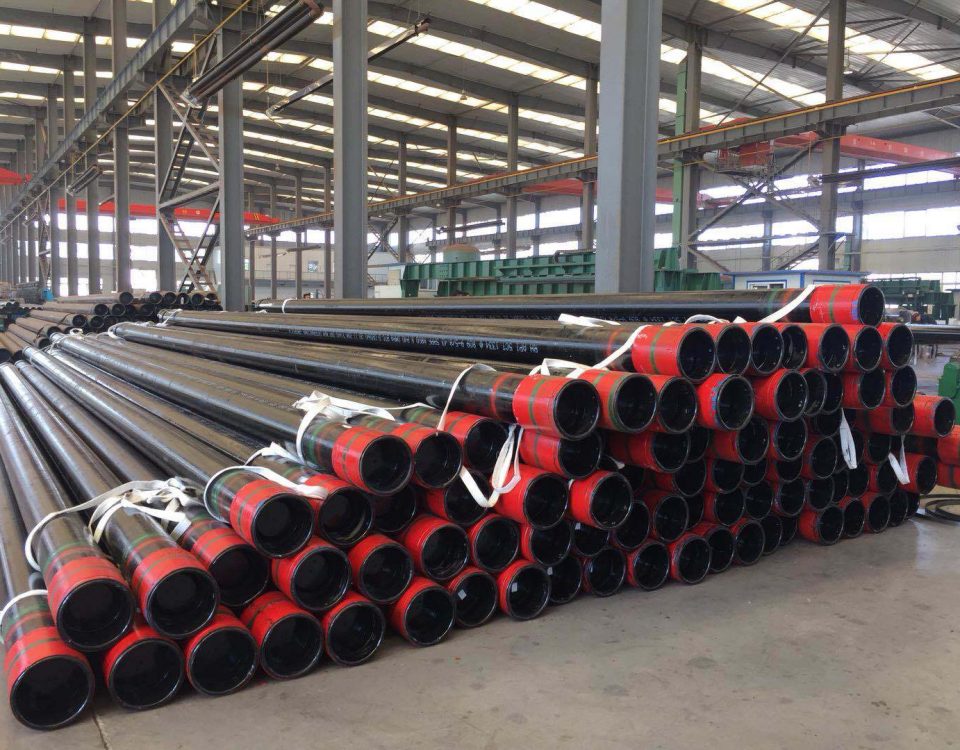

API 5ct Well Casing pipe: Casings are used for fixing the well wall or down hole, which have wide diameters, can be divided into conductor casings, technical casings and Oil casings.

dimensions of API 5CT casing

1. Steel grade:J55, K55, L80, N80, P110

2. outside diameters:4 1/2″, 5″, 5 1/2″, 6 5/8″, 7″, 7 5/8″, 9 5/8″, 10 3/4″, 13 3/8″, 16″, 18 5/8″, 20″

3. Wall thickness:5.21 – 16.13 mm

4. Thread type: SC( Short round string), LC( Long round thread), BC( Buttress string).

5. Length:R1( 4.88-7.62 m), R2( 7.62-10.36 m), R3( 10.36-14.63 m).

API 5CT K55 CASING PIPE

The API J55 casing and tubing have wide applications used in the shallow wells, geothermal wells, and water wells in the oil and natural gas fields. WLD steel is a leading API 5CT casing and tubing manufacturer and supplier, we provide not only a broad range of API 5CT K55 oilfield casing and API 5CT K55 tubing but also casing coupling, perforated pipe and more.

API 5CT K55 Chemical Composition

| Grade |

C≤ |

Si≤ |

Mn≤ |

P≤ |

S≤ |

Cr≤ |

Ni≤ |

Cu≤ |

Mo≤ |

V≤ |

| API 5CT K55 |

0.34-0.39 |

0.20-0.35 |

1.25-1.50 |

0.020 |

0.015 |

0.15 |

0.20 |

0.20 |

/ |

/ |

API 5CT K55 Mechanical Property

| Steel Grade |

Yield Strength (Mpa) |

Tensile Strength (Mpa) |

Total elongation under load % |

| API 5CT K55 |

379-552 |

≥655 |

0.5 |

API 5CT K55 Tolerance

| Item |

Allowable tolerance |

| Outer diameter |

Pipe body |

D≤101.60mm±0.79mm |

| D≥114.30mm+1.0% |

| -0.5% |

API 5CT K55 Size Chart

| Outer Diameter |

Wall Thickness |

Weight |

Grade |

Threaded |

Length |

| in |

mm |

kg/m |

lb/ft |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

API 5CT J55 CASING PIPE

The API J55 casing and tubing have wide application used in the shallow wells, geothermal wells, and water wells in the natural gas and coalbed methane due to its lower price relatively. WLD steel is a leading API 5CT casing and tubing manufacturer and supplier, we provide not only a broad range of API 5CT J55 oilfield casing pipe and API 5CT J55 tubing but also casing coupling, perforated pipe and more.

API 5CT J55 Chemical Composition

| Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

| API 5CT J55 |

0.34-0.39 |

0.20-0.35 |

1.25-1.50 |

0.020 |

0.015 |

0.15 |

0.20 |

0.20 |

/ |

API 5CT J55 Mechanical Property

| Steel Grade |

Yield Strength (Mpa) |

Tensile Strength (Mpa) |

Total elongation under load % |

| API 5CT J55 |

379-552 |

≥517 |

0.5 |

API 5CT J55 Tolerance

| Item |

Allowable tolerance |

| Outer diameter |

Pipe body |

D≤101.60mm±0.79mm |

| D≥114.30mm+1.0% |

| -0.5% |

| Wall thickness |

-12.5% |

| Wight |

Single piece |

+6.5%+3.5% |

| Total weight |

-1.75 |

API 5CT J55 Size Chart

| Outer Diameter |

Wall Thickness |

Weight |

Grade |

Threaded |

Length |

| in |

mm |

kg/m |

lb/ft |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

API 5CT N80 CASING PIPE

There is two types for API 5CT N80 oilfield casing pipes: N80-1 and N80-Q types, which have the same chemical composition and mechanical attributes while just various in the heat treatment. N801 steel pipe is treated by normalizing and tempering and N80Q is treated by quenching and tempering. The collapsing strength and internal pressure strength of N80Q are higher than that of N801 correspondingly.

API 5CT N80 Casing Tubing Color Code

| Name |

Casing |

Coupling |

| N80-1 |

a bright red band |

entire red coupling |

| N80-Q |

a bright red band + a green band |

entire red coupling + a green band |

API 5CT N80 Chemical Composition

| Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

| N80 type1/Q |

0.34-0.38 |

0.20-0.35 |

1.45-1.70 |

0.020 |

0.015 |

0.15 |

/ |

/ |

/ |

API 5CT N80 Mechanical Property

| Grades |

Yield Strength (Mpa) |

Tensile Strength (Mpa) |

Elongation under load, % |

| N80 type 1 |

552-758 |

689 |

0.5 |

| N80 type Q |

552-758 |

689 |

0.5 |

API 5CT N80 Tolerance

| Item |

Allowable tolerance |

| Outer diameter |

Pipe body |

D≤101.60mm±0.79mm |

| D≥114.30mm+1.0% |

| -0.5% |

| Wall thickness |

-12.5% |

| Wight |

Single piece |

+6.5%+3.5% |

| Total weight |

-1.75 |

API 5CT N80 Size Chart

| Outer Diameter |

Wall Thickness |

Weight |

Grade |

Threaded |

Length |

| in |

mm |

kg/m |

lb/ft |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

There are three types for API 5CT L80 oilfield casing pipes: L80 type 1, L80 type 9Cr, and L80 type 13Cr. L80 type 1 is utilized during the H2S condition, while L80 type 9Cr and 13Cr are used for the CO2 application. WLD steel is a leading API 5CT casing and tubing manufacturer and supplier, we provide not only a broad range of API 5CT L80 oilfield casing pipe and API 5CT L80 tubing but also casing coupling, perforated pipe and more.

API 5CT Grade L80 Casing Tubing Color Codes

| Name |

Casing |

Coupling |

| L80-1 |

A red band + a brown band |

Entire red coupling + a brown band |

API 5CT L80 Chemical Composition

| Grade |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

| API 5CT L80 |

0.15-0.22 |

1.00 |

0.25-1.00 |

≤0.020 |

≤0.010 |

12.0-14.0 |

0.20 |

0.20 |

API 5CT L80 Mechanical Property

| Grades |

Yield Strength (Mpa) |

Tensile Strength (Mpa) |

Elongation under load, % |

Hardness, HRC |

| L80 type 1 |

552-655 |

655 |

0.5 |

23 |

| L80 type 9Cr |

552-655 |

655 |

0.5 |

23 |

| L80 type 13Cr |

552-655 |

655 |

0.5 |

23 |

API 5CT L80 Tolerance

| Item |

Allowable tolerance |

| Outer diameter |

Pipe body |

D≤101.60mm±0.79mm |

| D≥114.30mm+1.0% |

| -0.5% |

| Wall thickness |

-12.5% |

| Wight |

Single piece |

+6.5%+3.5% |

| Total weight |

-1.75 |

API 5CT L80 Size Chart

| Outer Diameter |

Wall Thickness |

Weight |

Grade |

Threaded |

Length |

| in |

mm |

kg/m |

lb/ft |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |