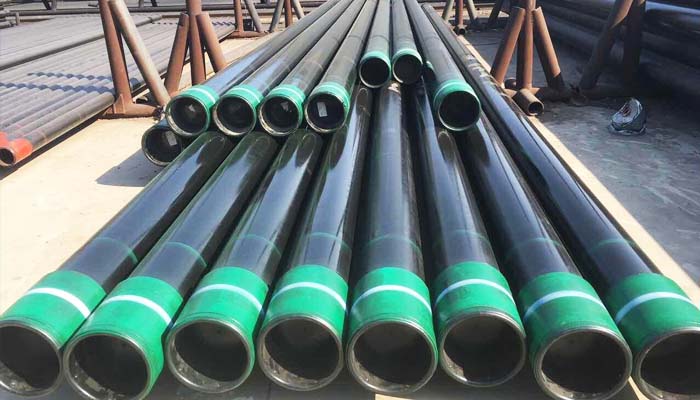

API 5CT tube: Tubes sont utilisés comme la pipe pour le transport de pétrole brut ou gaz naturel de la couche de l’huile à la surface, ours peuvent mieux pression durant la production de pétrole ou de gaz, et avoir un diamètre plus petit.

API 5CT bien Tuyaux de cuvelage: Les boyaux sont utilisés pour la fixation au mur bien ou dans le terrier, qui ont des diamètres de larges, peut être divisé en boyaux de chef d’orchestre, enveloppes techniques et carters d’huile.

Dimensions des API boîtier 5CT

1. Nuance d'acier:J55, K55, L80, N80, P110

2. diamètres extérieurs:4 1/2″, 5″, 5 1/2″, 6 5/8″, 7″, 7 5/8″, 9 5/8″, 10 3/4″, 13 3/8″, 16″, 18 5/8″, 20″

3. épaisseur du mur:5.21 – 16.13 mm

4. Type de fil: SC( Courte chaîne ronde), LC( Tour de long fil), avant JC( Chaîne de contrefort).

5. Longueur:R1( 4.88-7.62 m), R2( 7.62-10.36 m), R3( 10.36-14.63 m).

API 5CT K55 Pipe de boîtier

Le boîtier et les tubes API J55 ont des applications larges utilisées dans les puits peu profonds, puits géothermiques, et les puits d'eau dans les champs de pétrole et de gaz naturel. WLD Steel est un fabricant et fournisseur de tubuls et de tubes API 5CT leader, Nous fournissons non seulement une large gamme de tubages API 5CT K55 et de tubes API 5CT K55, mais aussi accouplement de boîtier, tuyau perforé et plus.

API 5CT Chiffre55 Composition chimique

| Noter |

C≤ |

Si≤ |

Mn≤ |

≤ |

S≤ |

CR≤ |

Ni≤ |

Cu≤ |

Mo≤ |

V≤ |

| API 5CT K55 |

0.34-0.39 |

0.20-0.35 |

1.25-1.50 |

0.020 |

0.015 |

0.15 |

0.20 |

0.20 |

/ |

/ |

API 5CT Chiffre55 Propriétés mécaniques

| Nuance d’acier |

Limite d’élasticité (MPa) |

Résistance à la traction (MPa) |

Allongement total sous charge % |

| API 5CT K55 |

379-552 |

≥655 |

0.5 |

API 5CT K55 Tolérance

| Ordre du jour |

Tolérance admissible |

| Diamètre extérieur |

Corps de canalisations |

D≤101,60 mm ± 0,79 mm |

| D≥114,30 mm + 1,0% |

| -0.5% |

API 5CT K55 Taille

| Diamètre extérieur |

Épaisseur de paroi |

Poids |

Noter |

Fileté |

Longueur |

| dans |

mm |

kg/m |

lb/pi |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

K55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

K55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

K55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

K55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

K55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

K55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

K55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

K55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

K55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

K55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

K55 |

LTC / STC / BTC |

R1 / R2 / R3 |

API 5CT J55 Pipe de boîtier

Le boîtier et les tubes API J55 ont une large application utilisée dans les puits peu profonds, puits géothermiques, et les puits d'eau dans le gaz naturel et le méthane de colbe en raison de son prix inférieur relativement. WLD Steel est un fabricant et fournisseur de tubuls et de tubes API 5CT leader, Nous fournissons non seulement une large gamme de tuyaux de boîtier de champ de gibier API 5CT J55 et de tubes API 5CT J55 mais également de couplage de boîtier, tuyau perforé et plus.

API 5CT J55 Composition chimique

| Noter |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

mois |

| API 5CT J55 |

0.34-0.39 |

0.20-0.35 |

1.25-1.50 |

0.020 |

0.015 |

0.15 |

0.20 |

0.20 |

/ |

API 5CT J55 Propriété mécanique

| Nuance d’acier |

Limite d’élasticité (MPa) |

Résistance à la traction (MPa) |

Allongement total sous charge % |

| API 5CT J55 |

379-552 |

≥517 |

0.5 |

API 5CT J55 Tolérance

| Ordre du jour |

Tolérance admissible |

| Diamètre extérieur |

Corps de canalisations |

D≤101,60 mm ± 0,79 mm |

| D≥114,30 mm + 1,0% |

| -0.5% |

| épaisseur du mur |

-12.5% |

| Se faire |

Simple |

+6.5%+3.5% |

| Poids total |

-1.75 |

API 5CT J55 Taille

| Diamètre extérieur |

Épaisseur de paroi |

Poids |

Noter |

Fileté |

Longueur |

| dans |

mm |

kg/m |

lb/pi |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

J55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

J55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

J55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

J55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

J55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

J55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

J55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

J55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

J55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

J55 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

J55 |

LTC / STC / BTC |

R1 / R2 / R3 |

API 5CT N80 Tuyau de boîtier

Il existe deux types pour API 5CT N80 OILFIED TIPES: Types N80-1 et N80-Q, qui ont la même composition chimique et les attributs mécaniques tout en étant divers dans le traitement thermique. Le tuyau en acier N801 est traité par normalisation et trempage et N80Q est traité par extinction et température. La résistance à l'effondrement et la résistance à la pression interne de N80q sont supérieures à celles de N801 en conséquence.

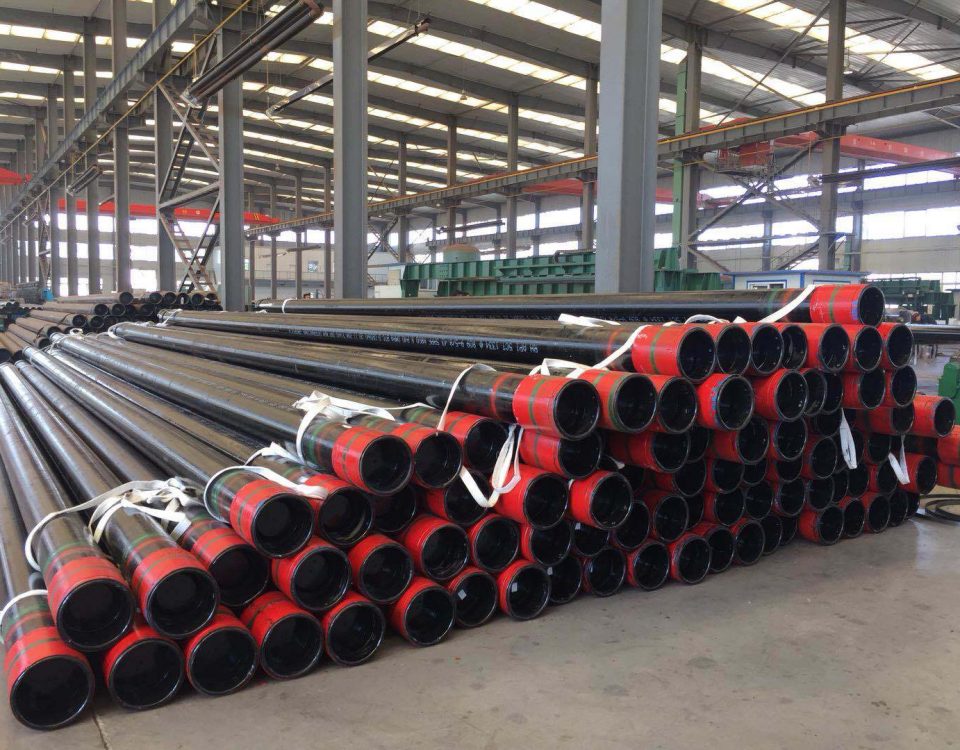

API 5CT N80 Code de couleur de tube en boîtier

| Nom |

Enveloppe |

Couplage |

| N80-1 |

une bande rouge vif |

accouplement rouge entier |

| N80-Q |

une bande rouge vif + une bande verte |

accouplement rouge entier + une bande verte |

API 5CT N80 Composition chimique

| Noter |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

mois |

| N80 TYPE1 / Q |

0.34-0.38 |

0.20-0.35 |

1.45-1.70 |

0.020 |

0.015 |

0.15 |

/ |

/ |

/ |

API 5CT N80 Propriété mécanique

| grades |

Limite d’élasticité (MPa) |

Résistance à la traction (MPa) |

Allongement sous charge, % |

| Type N80 1 |

552-758 |

689 |

0.5 |

| N80 Type Q |

552-758 |

689 |

0.5 |

API 5CT N80 Tolérance

| Ordre du jour |

Tolérance admissible |

| Diamètre extérieur |

Corps de canalisations |

D≤101,60 mm ± 0,79 mm |

| D≥114,30 mm + 1,0% |

| -0.5% |

| épaisseur du mur |

-12.5% |

| Se faire |

Simple |

+6.5%+3.5% |

| Poids total |

-1.75 |

API 5CT N80 Taille du tableau

| Diamètre extérieur |

Épaisseur de paroi |

Poids |

Noter |

Fileté |

Longueur |

| dans |

mm |

kg/m |

lb/pi |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

N80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

N80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

N80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

N80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

N80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

N80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

N80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

N80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

N80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

N80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

N80 |

LTC / STC / BTC |

R1 / R2 / R3 |

Il existe trois types pour API 5CT L80 OILFIED TIPES: Type L80 1, L80 TYPE 9CR, et L80 Type 13CR. Type L80 1 est utilisé pendant la condition H2S, tandis que L80 Type 9CR et 13CR sont utilisés pour l'application CO2. WLD Steel est un fabricant et fournisseur de tubuls et de tubes API 5CT leader, Nous fournissons non seulement une large gamme de tuyaux de tubage API 5CT L80 à huile et de tuyaux API 5CT L80 mais également couplage de boîtier, tuyau perforé et plus.

API 5CT GRADE L80 CODES DE COULEUR DE TUBILES

| Nom |

Enveloppe |

Couplage |

| L80-1 |

Un groupe rouge + une bande marron |

Couplage rouge entier + une bande marron |

API 5CT L80 Composition chimique

| Noter |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

| API 5CT L80 |

0.15-0.22 |

1.00 |

0.25-1.00 |

≤0.020 |

≤0.010 |

12.0-14.0 |

0.20 |

0.20 |

API 5CT L80 Propriété mécanique

| grades |

Limite d’élasticité (MPa) |

Résistance à la traction (MPa) |

Allongement sous charge, % |

Dureté, HRC |

| Type L80 1 |

552-655 |

655 |

0.5 |

23 |

| L80 TYPE 9CR |

552-655 |

655 |

0.5 |

23 |

| Type L80 13Cr |

552-655 |

655 |

0.5 |

23 |

API 5CT L80 Tolérance

| Ordre du jour |

Tolérance admissible |

| Diamètre extérieur |

Corps de canalisations |

D≤101,60 mm ± 0,79 mm |

| D≥114,30 mm + 1,0% |

| -0.5% |

| épaisseur du mur |

-12.5% |

| Se faire |

Simple |

+6.5%+3.5% |

| Poids total |

-1.75 |

API 5CT L80 Taille du tableau

| Diamètre extérieur |

Épaisseur de paroi |

Poids |

Noter |

Fileté |

Longueur |

| dans |

mm |

kg/m |

lb/pi |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

L80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

L80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

L80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

L80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

L80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

L80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

L80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

L80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

L80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

L80 |

LTC / STC / BTC |

R1 / R2 / R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

L80 |

LTC / STC / BTC |

R1 / R2 / R3 |