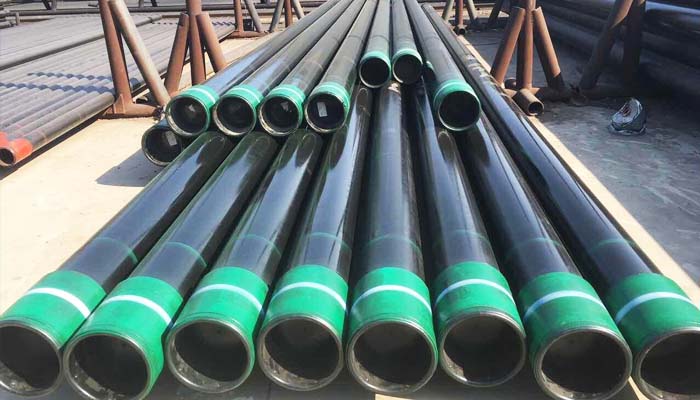

Tubulação de API 5CT: Tubulações são utilizadas como tubos para o transporte de petróleo ou gás natural da camada do óleo à superfície, urso pode melhor pressão durante a produção de petróleo ou gás, e ter diâmetros menores.

API 5CT bem Tubo de revestimento: Tripas são utilizadas para a fixação na parede bem ou buraco, que têm diâmetros amplo, podem ser divididos em invólucros de condutor, técnicos invólucros e embalagens de óleo.

dimensões da API revestimento 5CT

1. Classe de aço:J55, K55, L80, N80, P110

2. diâmetros externos:4 1/2″, 5″, 5 1/2″, 6 5/8″, 7″, 7 5/8″, 9 5/8″, 10 3/4″, 13 3/8″, 16″, 18 5/8″, 20″

3. espessura da parede:5.21 – 16.13 mm

4. Tipo de fio: SC( Sequência de caracteres redonda curta), LC( Redondo longo segmento), A.C.( Sequência do contraforte).

5. comprimento:R1( 4.88-7.62 m), R2( 7.62-10.36 m), R3( 10.36-14.63 m).

API 5CT K55 CASING PIPE

The API J55 casing and tubing have wide applications used in the shallow wells, poços geotérmicos, and water wells in the oil and natural gas fields. WLD steel is a leading API 5CT casing and tubing manufacturer and supplier, we provide not only a broad range of API 5CT K55 oilfield casing and API 5CT K55 tubing but also acoplamento de revestimento, perforated pipe and more.

API 5CT K55 Composição química

| Grau |

C≤ |

Si≤ |

Mn≤ |

P ≤ |

S≤ |

CR≤ |

Ni≤ |

Cu≤ |

Mo≤ |

V≤ |

| API 5CT K55 |

0.34-0.39 |

0.20-0.35 |

1.25-1.50 |

0.020 |

0.015 |

0.15 |

0.20 |

0.20 |

/ |

/ |

API 5CT K55 Propriedade mecânica

| Classe de aço |

Força de rendimento (MPa) |

Resistência à tração (MPa) |

Alongamento total sob carga % |

| API 5CT K55 |

379-552 |

≥655 |

0.5 |

API 5CT K55 Tolerance

| Item |

Allowable tolerance |

| Diâmetro externo |

Corpo da tubulação |

D≤101.60mm±0.79mm |

| D≥114.30mm+1.0% |

| -0.5% |

API 5CT K55 Size Chart

| Diâmetro exterior |

Espessura de parede |

Peso |

Grau |

Rosca |

comprimento |

| em |

mm |

kg/m |

lb / pé |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

API 5CT J55 CASING PIPE

The API J55 casing and tubing have wide application used in the shallow wells, poços geotérmicos, and water wells in the natural gas and coalbed methane due to its lower price relatively. WLD steel is a leading API 5CT casing and tubing manufacturer and supplier, we provide not only a broad range of API 5CT J55 oilfield casing pipe and API 5CT J55 tubing but also casing coupling, perforated pipe and more.

API 5CT J55 Chemical Composition

| Grau |

C |

Si |

MN |

P |

S |

CR |

Ni |

Cu |

Mo |

| API 5CT J55 |

0.34-0.39 |

0.20-0.35 |

1.25-1.50 |

0.020 |

0.015 |

0.15 |

0.20 |

0.20 |

/ |

API 5CT J55 Mechanical Property

| Classe de aço |

Força de rendimento (MPa) |

Resistência à tração (MPa) |

Alongamento total sob carga % |

| API 5CT J55 |

379-552 |

≥517 |

0.5 |

API 5CT J55 Tolerance

| Item |

Allowable tolerance |

| Diâmetro externo |

Corpo da tubulação |

D≤101.60mm±0.79mm |

| D≥114.30mm+1.0% |

| -0.5% |

| espessura da parede |

-12.5% |

| Wight |

Single piece |

+6.5%+3.5% |

| Peso total |

-1.75 |

API 5CT J55 Size Chart

| Diâmetro exterior |

Espessura de parede |

Peso |

Grau |

Rosca |

comprimento |

| em |

mm |

kg/m |

lb / pé |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

API 5CT N80 CASING PIPE

There is two types for API 5CT N80 oilfield casing pipes: N80-1 and N80-Q types, which have the same chemical composition and mechanical attributes while just various in the heat treatment. N801 steel pipe is treated by normalizing and tempering and N80Q is treated by quenching and tempering. The collapsing strength and internal pressure strength of N80Q are higher than that of N801 correspondingly.

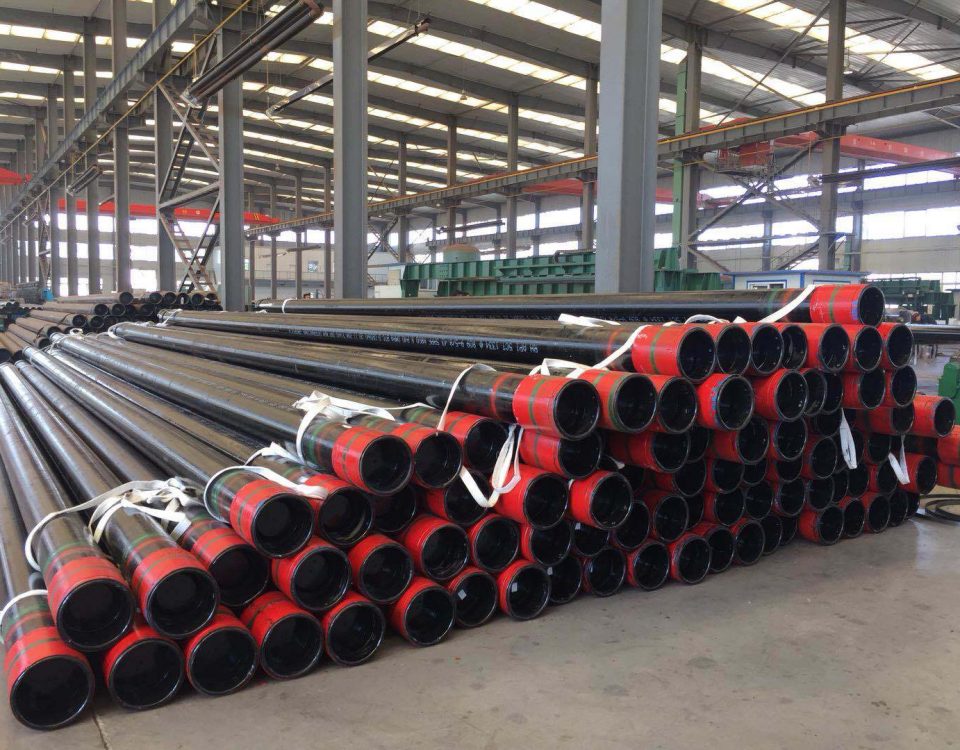

API 5CT N80 Casing Tubing Color Code

| Nome |

Letras maiusculas e minúsculas |

Acoplamento |

| N80-1 |

uma faixa vermelha brilhante |

acoplamento vermelho inteiro |

| N80-Q |

uma faixa vermelha brilhante + uma faixa verde |

acoplamento vermelho inteiro + uma faixa verde |

API 5CT N80 Chemical Composition

| Grau |

C |

Si |

MN |

P |

S |

CR |

Ni |

Cu |

Mo |

| N80 type1/Q |

0.34-0.38 |

0.20-0.35 |

1.45-1.70 |

0.020 |

0.015 |

0.15 |

/ |

/ |

/ |

API 5CT N80 Mechanical Property

| Notas |

Força de rendimento (MPa) |

Resistência à tração (MPa) |

Elongation under load, % |

| N80 type 1 |

552-758 |

689 |

0.5 |

| N80 type Q |

552-758 |

689 |

0.5 |

API 5CT N80 Tolerance

| Item |

Allowable tolerance |

| Diâmetro externo |

Corpo da tubulação |

D≤101.60mm±0.79mm |

| D≥114.30mm+1.0% |

| -0.5% |

| espessura da parede |

-12.5% |

| Wight |

Single piece |

+6.5%+3.5% |

| Peso total |

-1.75 |

API 5CT N80 Size Chart

| Diâmetro exterior |

Espessura de parede |

Peso |

Grau |

Rosca |

comprimento |

| em |

mm |

kg/m |

lb / pé |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

There are three types for API 5CT L80 oilfield casing pipes: L80 type 1, L80 type 9Cr, and L80 type 13Cr. L80 type 1 is utilized during the H2S condition, while L80 type 9Cr and 13Cr are used for the CO2 application. WLD steel is a leading API 5CT casing and tubing manufacturer and supplier, we provide not only a broad range of API 5CT L80 oilfield casing pipe and API 5CT L80 tubing but also casing coupling, perforated pipe and more.

API 5CT Grade L80 Casing Tubing Color Codes

| Nome |

Letras maiusculas e minúsculas |

Acoplamento |

| L80-1 |

A red band + uma faixa marrom |

Entire red coupling + uma faixa marrom |

API 5CT L80 Chemical Composition

| Grau |

C |

Si |

MN |

P |

S |

CR |

Ni |

Cu |

| API 5CT L80 |

0.15-0.22 |

1.00 |

0.25-1.00 |

≤0.020 |

≤0.010 |

12.0-14.0 |

0.20 |

0.20 |

API 5CT L80 Mechanical Property

| Notas |

Força de rendimento (MPa) |

Resistência à tração (MPa) |

Elongation under load, % |

Dureza, HRC |

| L80 type 1 |

552-655 |

655 |

0.5 |

23 |

| L80 type 9Cr |

552-655 |

655 |

0.5 |

23 |

| L80 tipo 13Cr |

552-655 |

655 |

0.5 |

23 |

API 5CT L80 Tolerance

| Item |

Allowable tolerance |

| Diâmetro externo |

Corpo da tubulação |

D≤101.60mm±0.79mm |

| D≥114.30mm+1.0% |

| -0.5% |

| espessura da parede |

-12.5% |

| Wight |

Single piece |

+6.5%+3.5% |

| Peso total |

-1.75 |

API 5CT L80 Size Chart

| Diâmetro exterior |

Espessura de parede |

Peso |

Grau |

Rosca |

comprimento |

| em |

mm |

kg/m |

lb / pé |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |