API 5ct boru: Makaronlar boru ham petrol veya doğal gaz su yüzüne çıkmaya yağ tabakası üzerinden taşımak için kullanılan, ayı daha iyi petrol veya doğal gaz üretim sırasında basınç, ve daha küçük çapları.

API 5ct Well Kasa boru: Mermi kovanı aşağı delik veya iyi duvar tespit için kullanılır, hangi-si olmak geniş çapları, kondüktörü kovanları ayrılabilir, Teknik kovanları ve petrol kovanları.

API boyutları 5CT kasa

1. Çelik sınıf:J55, K55, L80, N80, P110

2. Dış çapları:4 1/2″, 5″, 5 1/2″, 6 5/8″, 7″, 7 5/8″, 9 5/8″, 10 3/4″, 13 3/8″, 16″, 18 5/8″, 20″

3. Duvar kalınlığı:5.21 – 16.13 mm

4. Konu türü: SC( Kısa yuvarlak dize), LC( Uzun yuvarlak iplik), MİLATTAN ÖNCE( Payandanın dize).

5. uzunluk:R1( 4.88-7.62 m), R2( 7.62-10.36 m), R3( 10.36-14.63 m).

API 5CT K55 CASING PIPE

The API J55 casing and tubing have wide applications used in the shallow wells, Jeotermal kuyu, and water wells in the oil and natural gas fields. WLD steel is a leading API 5CT casing and tubing manufacturer and supplier, we provide not only a broad range of API 5CT K55 oilfield casing and API 5CT K55 tubing but also gövde kaplini, perforated pipe and more.

API 5CT K55 Kimyasal bileşimi

| Sınıf |

C≤ |

Si≤ |

Mn≤ |

p≤ |

S≤ |

CR≤ |

Ni≤ |

Cu≤ |

Mo≤ |

V≤ |

| API 5CT K55 |

0.34-0.39 |

0.20-0.35 |

1.25-1.50 |

0.020 |

0.015 |

0.15 |

0.20 |

0.20 |

/ |

/ |

API 5CT K55 Mekanik özelliği

| Çelik sınıf |

Verim gücü (MPA) |

Çekme dayanımı (MPA) |

Yük altında toplam uzama % |

| API 5CT K55 |

379-552 |

≥655 |

0.5 |

API 5CT K55 Tolerance

| Madde |

Allowable tolerance |

| Dış çap |

Boru gövdesi |

D≤101.60mm±0.79mm |

| D≥114.30mm+1.0% |

| -0.5% |

API 5CT K55 Size Chart

| Dış çap |

Duvar kalınlığı |

Ağırlık |

Sınıf |

Dişli |

uzunluk |

| içinde |

mm |

kg/m |

lb / ft |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

K55 |

LTC/STC/BTC |

R1/R2/R3 |

API 5CT J55 CASING PIPE

The API J55 casing and tubing have wide application used in the shallow wells, Jeotermal kuyu, and water wells in the natural gas and coalbed methane due to its lower price relatively. WLD steel is a leading API 5CT casing and tubing manufacturer and supplier, we provide not only a broad range of API 5CT J55 oilfield casing pipe and API 5CT J55 tubing but also casing coupling, perforated pipe and more.

API 5CT J55 Chemical Composition

| Sınıf |

C |

Si |

MN |

P |

S |

CR |

Ni |

Cu |

sen |

| API 5CT J55 |

0.34-0.39 |

0.20-0.35 |

1.25-1.50 |

0.020 |

0.015 |

0.15 |

0.20 |

0.20 |

/ |

API 5CT J55 Mechanical Property

| Çelik sınıf |

Verim gücü (MPA) |

Çekme dayanımı (MPA) |

Yük altında toplam uzama % |

| API 5CT J55 |

379-552 |

≥517 |

0.5 |

API 5CT J55 Tolerance

| Madde |

Allowable tolerance |

| Dış çap |

Boru gövdesi |

D≤101.60mm±0.79mm |

| D≥114.30mm+1.0% |

| -0.5% |

| Duvar kalınlığı |

-12.5% |

| Wight |

Single piece |

+6.5%+3.5% |

| Toplam ağırlık |

-1.75 |

API 5CT J55 Size Chart

| Dış çap |

Duvar kalınlığı |

Ağırlık |

Sınıf |

Dişli |

uzunluk |

| içinde |

mm |

kg/m |

lb / ft |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

J55 |

LTC/STC/BTC |

R1/R2/R3 |

API 5CT N80 Muhafaza Borusu

There is two types for API 5CT N80 oilfield casing pipes: N80-1 and N80-Q types, which have the same chemical composition and mechanical attributes while just various in the heat treatment. N801 steel pipe is treated by normalizing and tempering and N80Q is treated by quenching and tempering. The collapsing strength and internal pressure strength of N80Q are higher than that of N801 correspondingly.

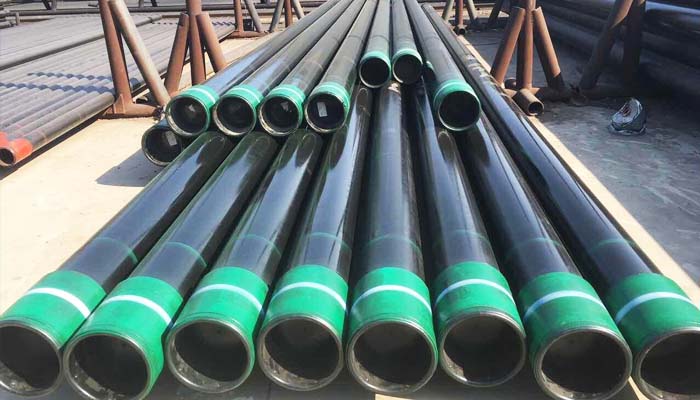

API 5CT N80 Casing Tubing Color Code

| Adı |

Kasa |

Kaplin |

| N80-1 |

parlak kırmızı bir bant |

tüm kırmızı bağlantı |

| N80-Q |

parlak kırmızı bir bant + yeşil bir bant |

tüm kırmızı bağlantı + yeşil bir bant |

API 5CT N80 Chemical Composition

| Sınıf |

C |

Si |

MN |

P |

S |

CR |

Ni |

Cu |

sen |

| N80 type1/Q |

0.34-0.38 |

0.20-0.35 |

1.45-1.70 |

0.020 |

0.015 |

0.15 |

/ |

/ |

/ |

API 5CT N80 Mechanical Property

| Notlar |

Verim gücü (MPA) |

Çekme dayanımı (MPA) |

Elongation under load, % |

| N80 type 1 |

552-758 |

689 |

0.5 |

| N80 type Q |

552-758 |

689 |

0.5 |

API 5CT N80 Tolerance

| Madde |

Allowable tolerance |

| Dış çap |

Boru gövdesi |

D≤101.60mm±0.79mm |

| D≥114.30mm+1.0% |

| -0.5% |

| Duvar kalınlığı |

-12.5% |

| Wight |

Single piece |

+6.5%+3.5% |

| Toplam ağırlık |

-1.75 |

API 5CT N80 Size Chart

| Dış çap |

Duvar kalınlığı |

Ağırlık |

Sınıf |

Dişli |

uzunluk |

| içinde |

mm |

kg/m |

lb / ft |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

N80 |

LTC/STC/BTC |

R1/R2/R3 |

There are three types for API 5CT L80 oilfield casing pipes: L80 type 1, L80 type 9Cr, and L80 type 13Cr. L80 type 1 is utilized during the H2S condition, while L80 type 9Cr and 13Cr are used for the CO2 application. WLD steel is a leading API 5CT casing and tubing manufacturer and supplier, we provide not only a broad range of API 5CT L80 oilfield casing pipe and API 5CT L80 tubing but also casing coupling, perforated pipe and more.

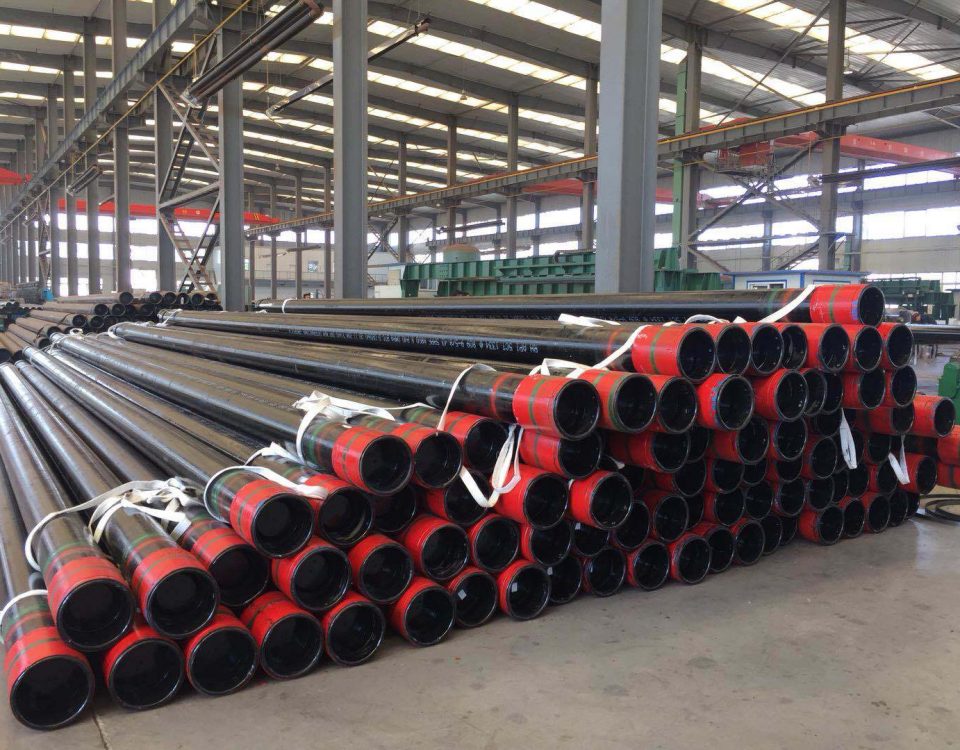

API 5CT Grade L80 Casing Tubing Color Codes

| Adı |

Kasa |

Kaplin |

| L80-1 |

A red band + kahverengi bir bant |

Entire red coupling + kahverengi bir bant |

API 5CT L80 Chemical Composition

| Sınıf |

C |

Si |

MN |

P |

S |

CR |

Ni |

Cu |

| API 5CT L80 |

0.15-0.22 |

1.00 |

0.25-1.00 |

≤0.020 |

≤0.010 |

12.0-14.0 |

0.20 |

0.20 |

API 5CT L80 Mechanical Property

| Notlar |

Verim gücü (MPA) |

Çekme dayanımı (MPA) |

Elongation under load, % |

Sertlik, HRC |

| L80 type 1 |

552-655 |

655 |

0.5 |

23 |

| L80 type 9Cr |

552-655 |

655 |

0.5 |

23 |

| L80 tipi 13Cr |

552-655 |

655 |

0.5 |

23 |

API 5CT L80 Tolerance

| Madde |

Allowable tolerance |

| Dış çap |

Boru gövdesi |

D≤101.60mm±0.79mm |

| D≥114.30mm+1.0% |

| -0.5% |

| Duvar kalınlığı |

-12.5% |

| Wight |

Single piece |

+6.5%+3.5% |

| Toplam ağırlık |

-1.75 |

API 5CT L80 Size Chart

| Dış çap |

Duvar kalınlığı |

Ağırlık |

Sınıf |

Dişli |

uzunluk |

| içinde |

mm |

kg/m |

lb / ft |

| 4 1/2″ |

114.3 |

14.14-22.47 |

9.50-11.50 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 5″ |

127 |

17.11-35.86 |

11.50-24.10 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 5 1/2″ |

139.7 |

20.83-34.23 |

14.00-23.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 6 5/8″ |

168.28 |

29.76-35.72 |

20.00-24.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 7″ |

177.8 |

25.30-56.55 |

17.00-38.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 7 5/8″ |

193.68 |

35.72-63.69 |

24.00-42.80 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 8 5/8″ |

219.08 |

35.72-72.92 |

24.00-49.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 9 5/8″ |

244.48 |

48.07-86.91 |

32.30-58.40 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 10 3/4″ |

273.05 |

48.73-97.77 |

32.75-65.70 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 11 3/4″ |

298.45 |

62.50-89.29 |

42.00-60.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |

| 13 3/8″ |

339.72 |

71.43-107.15 |

48.00-72.00 |

L80 |

LTC/STC/BTC |

R1/R2/R3 |