API 5CT J55 Seamless oil Casing and tubing,OTCG casing R3, 13-3/8 Inch

December 8, 2016

API 5CT well casing steel pipes, J55 K55 N80 L80 oil casing pipes

December 13, 2016ASTM A53 is a carbon steel alloy, used as structural steel or for low-pressure pipes. The alloy specifications are established by ASTM International, in requirements ASTM A53/A53M.

A53 pipeline is available in 3 kinds as well as 2 qualities, A53 Type F, which is longitudinally heating system butt welded or continuous bonded (Grade An only), A53 Type E, which is longitudinally electrical resistance bonded (Grades An and also B), and also A53 Type S, which is seamless pipeline, produced by hot working, and also possibly cool ending up, the steel (Qualities An as well as B). ASTM A53 pipeline is sized according to the nominal pipeline dimension (NPS) system. It is generally readily available with national pipe string finishes or with simple cut ends. It can be utilized for heavy steam, water, and also air conveyance. It is likewise weldable and also could be made use of in architectural applications, although ASTM A500 tube, which is offered in the same NPS sizes, is sometime liked.

This is a standard set by the requirements company ASTM International, a voluntary criteria growth organizations that establishes technological criteria for materials, products, systems, and also solutions.

Chemical Properties % of ASTM A53

|

It’s common in the STD ERW pipe field that the max. size is 660mm. But the innovation is developed as well as some mill also could generate od 720 STD ERW pipelines for large diameter application pipes in engineering fields as per ASTM A53 spec, API 5L typical and so on. Abter Steel Pipeline is advanced equipped and also is able to maker 660mm routine std ERW pipeline in fully grown innovation and also extremely conventional item treatment.

Larger diameter 660mm ERW pipe timetable in SCH20, SCH 30, SCH 40 sexually transmitted disease could be extra extensively utilized in gas and also oil line pipe transportation, building and construction of bridge or structure. As ERW pipe is a lot more cost-saved than LSAW(longitudinal below merged arc welded pipeline) and have far better homes compared to SSAW (spiral sub-merged arc welding pipe). Larger diameter ERW pipeline and also tube will remain in larger need in applications like gas & oil areas, loading piles, building and constructions and so on.

specifications of ASTM A53 ERW Pipes, GR.B, OD 660mm STD oil line pipes

| Product Name | ASTM A53 ERW Pipes, GR.B, OD 660mm STD oil line pipes |

| STD ERW Pipe Diameter | 26 inch / 660mm |

| Diameter Tolerance | 653.4mm~ 666.6mm (acc. to ASTM A53, +/-1% of outside diameter) |

| Wall Thickness | STD / 9.53mm |

| Wall Thickness Tolerance | 8.34~10.72mm (acc. to ASTM A53, +/- 12.5%t) |

| STD ERW Pipe Standard | ASTM A53 B, API 5L B, CSA Z245, A106 B |

| STD ERW Pipe Grade | Grade B, Gr.B, GRB, G.B other steel grade required |

| Pipe Test | Hydro test, UT test, Flatten test, Impact test, Tensile test, Yield strength test etc |

| Hydro test pressure | 610 psi [4200 kMpa] As per ASTM A53 Spec |

| STD ERW Pipe Length | SRL, DRL, Random length from 3m to 18m |

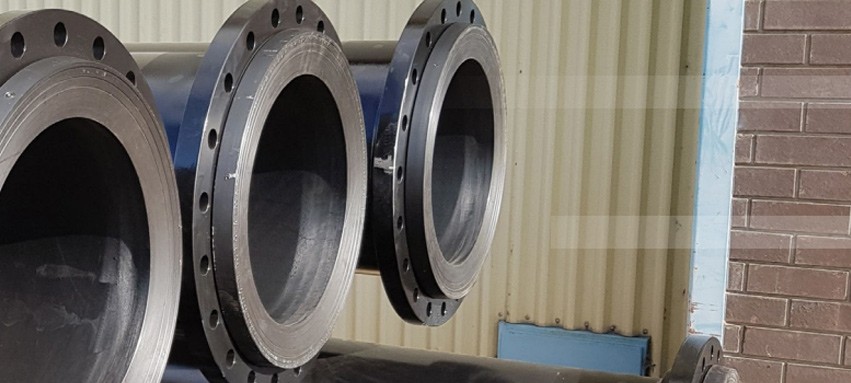

| End Finish | Beveled ends with caps or steel protector or plain ends or plain ends per request. |

| STD ERW Pipe Application | Fluid pipe, piling pipe,line pipe, structure steel tube,water pipe, construction pipe, bridge pipe etc. |

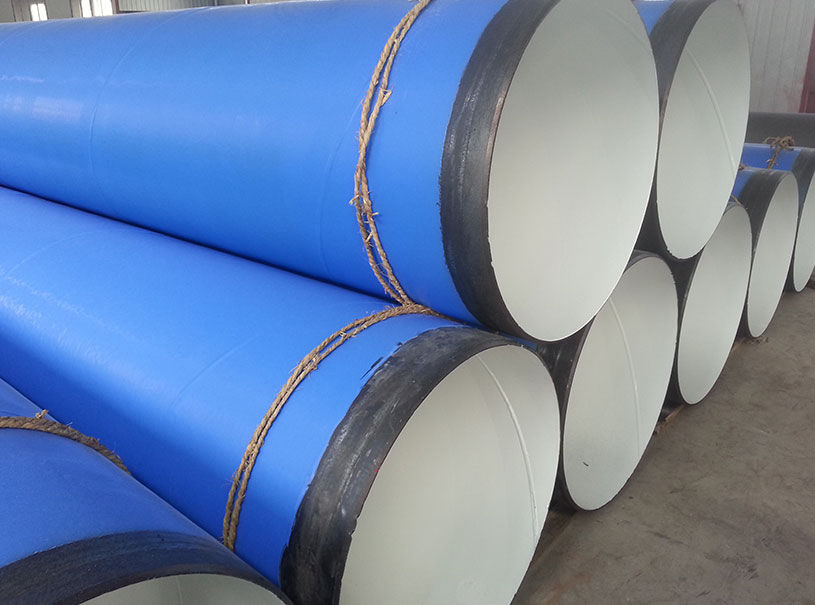

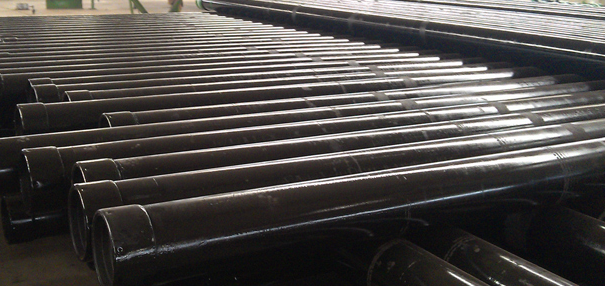

| Pipe Coating | Black painting, varnish, anti rust oil, FBE, 3PE, 3 layer PE, 3PP etc. |