API 5CT well casing steel pipes, J55 K55 N80 L80 oil casing pipes

December 13, 2016API 5CT CASING TUBING ,Couplings, pup joints Testing of chemical composition

December 17, 2016API 5L is a more comprehensive specification mainly developed for line pipes used in oil and gas industry; the range of strength grades is much wider. While the lower strength grades grades A & B are comparable to A106, the other grades have much higher strengths (e.g. X42, X56, X60,…etc). Also, the quality grades are more stringent when API 5L Line Pipe PSL2 is applied where as rolled grades are not acceptable and rework is not allowed. Moreover, particular attention is given to toughness and toughness tests for sour services and higher pressure/ temperature classes.

API 5L Grade B PSL1 ERW Pipes Chemical Composition

| Steel grade (Steel name) | Mass fraction, based upon heat and product analyses | |||||||

|---|---|---|---|---|---|---|---|---|

| C | Mn | P | S | V | Nb | Ti | ||

|

Welded pipe

|

||||||||

| L245 or B | 0,26 | 1,20 | 0,030 | 0,030 | c,d | c,d | d | |

API 5L Grade B PSL1 ERW Steel Tube Mechanical Properties

| Pipe grade | Pipe body of seamless and welded pipes | Weld seam of EW, SAW and COW pipes | ||

|---|---|---|---|---|

| Yield strength aRt0,5 MPa (psi) minimum | Tensile strengtha Rm MPa (psi) minimum | ElongationAf % minimum | Tensile strengthb Rm MPa (psi) minimum | |

Physical Properties of API

| API 5L Grade | Yield Strength min. (ksi) |

Tensile Strength min. (ksi) |

Yield to Tensile Ratio (max.) |

Elongation min. %1 |

|---|---|---|---|---|

| A | 30 | 48 | 0.93 | 28 |

| B | 35 | 60 | 0.93 | 23 |

| X42 | 42 | 60 | 0.93 | 23 |

| X46 | 46 | 63 | 0.93 | 22 |

| X52 | 52 | 66 | 0.93 | 21 |

| X56 | 56 | 71 | 0.93 | 19 |

| X60 | 60 | 75 | 0.93 | 19 |

| X65 | 65 | 77 | 0.93 | 18 |

| X70 | 70 | 82 | 0.93 | 17 |

| X80 | 80 | 90 | 0.93 | 16 |

Specification of API 5L carbon steel pipes, X60, SCH30,RDL line pipe

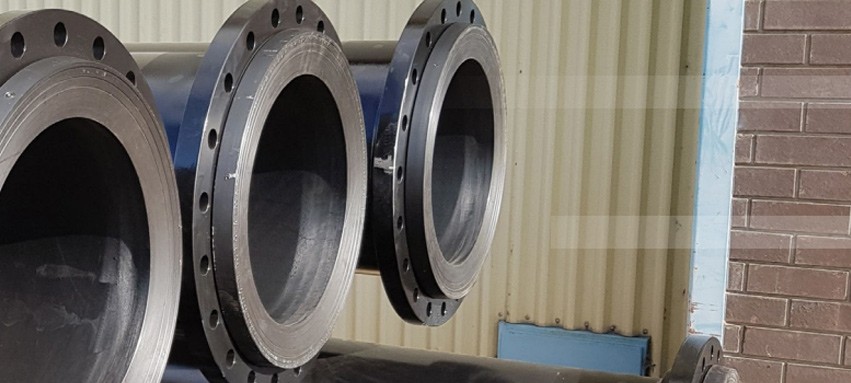

| Product Name |

API 5L X60 carbon steel Pipe |

| Diameter | 1inch– 26inch |

| Wall Thickness | SCH10,SCH 20,SCH 30,STD,SCH 40, SCH60 etc |

| Length | Random length from 3m to 18m |

| Pipe Standard | API 5L, ASTM A53, A106, EN10219,EN10210 |

| Steel Grade | GRA, GR B, X42, X46, X52, X56, X60, X65, X70, S275, S355 |

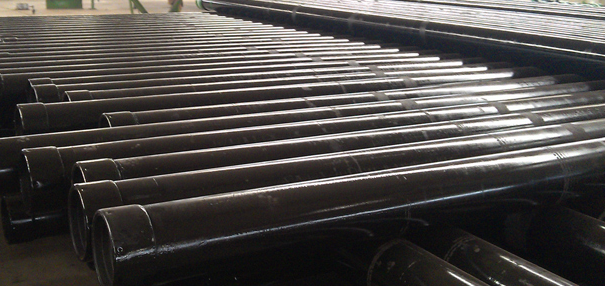

| Application | Linepipe, fluid pipe, water pipe, structure steel tube,piling tube, |

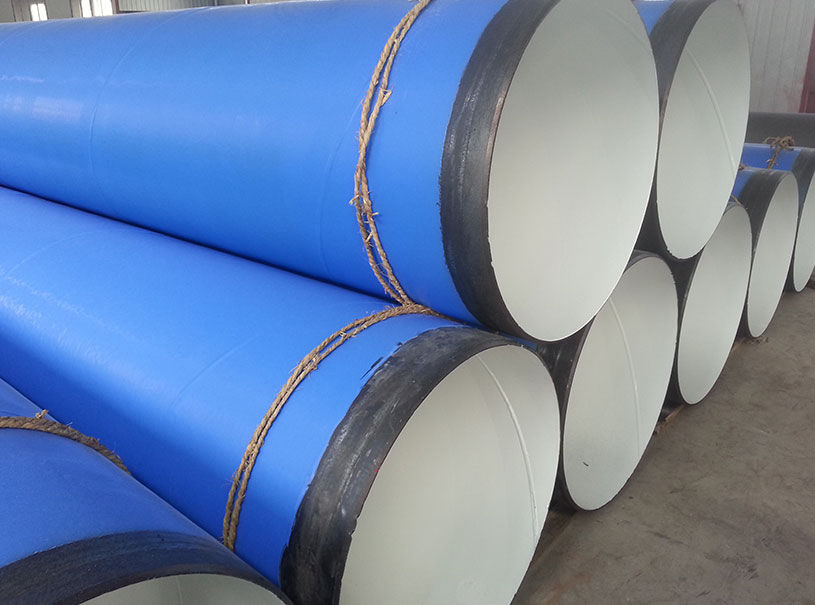

| Pipe Coating | Black painting, varnish paint, anti rust oil, or other coating required |