API SPEC 5CT J55 oil casing and tubing,Seamless Steel Tubes

February 13, 2017

Welded Steel pipe (erw & spiral) specification and Manufacturing method

February 15, 2017Steel casing is kind of pipe that normally runs underground. It can be utilized to protect items inside the pipeline or to provide an additional barrier between the matter in the pipeline and the earth. Another name for these products is encasement pipelines.

The pipes are typically placed in the ground in separate sectors and then bonded together. In some cases, pipeline can be threaded through a pre-existing hole or tunnel. The latter technique is generally needed since the hole was drilled, instead of dug from ground level, due to an obstruction such as a roadway or a river.

Tubing is pipe used for the transportation of crude oil and natural gas from an oil or gas layer to the surface after drilling is complete. It is made to withstand the pressure generated from the extraction process. Tubing is manufactured in the same way as casing, except that an additional process known as “upsetting” is applied to thicken the pipes.

Specification API 5CT casing and tubing:

Outer Diameter:Casing: OD 4 1/2″- 20″ (114.3mm-508mm)

Tubing: OD 2 3/8″ – 4 1/2″ (60.3mm-114.30mm)

Wall Thickness: 0. 205″- 0.635″

Grade: J55,N80-1,N80-Q,L80-1,L80-9cr,C90,T95,P110,Q125

Length: R1(4.88mtr-7.62mtr), R2(7.62mtr-10.36mtr), R3(10.36mtr or longer)

Tread type: Casing: LTC, STC, BTC.Tubing: NUE, EUE.

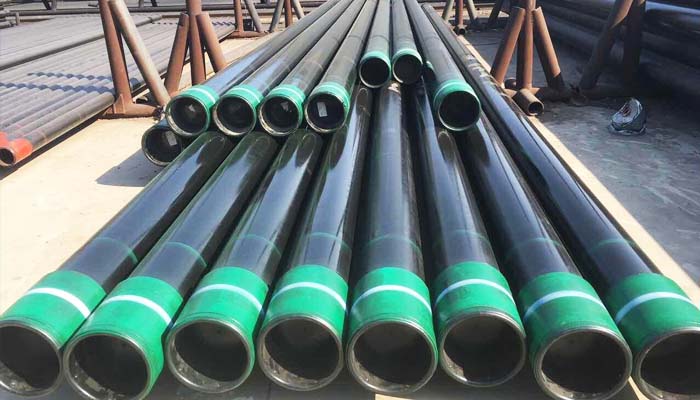

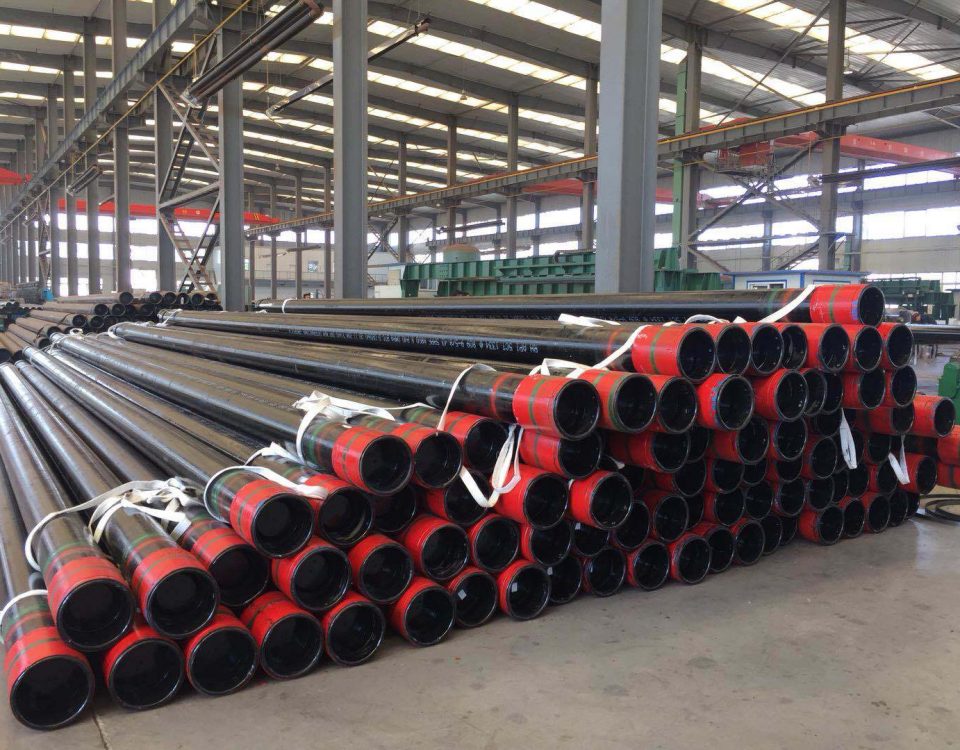

End: Beveled, Square cut. And pipe protection cap specially for casing and tubing.

Surface: Corrosion proofing water based paint

Heat treatment: Normalized, Quencher+Temper

Test: Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Flaring Test, Bending Test, Hardness Test, Blow Test, Impact Test etc), Exterior Size Inspection, Nondestructive Test (Ultrasonic flaw detector, Eddy current flaw detector), Hydrostatic Test.