galvanized steel pipe

June 26, 2016

drill pipe

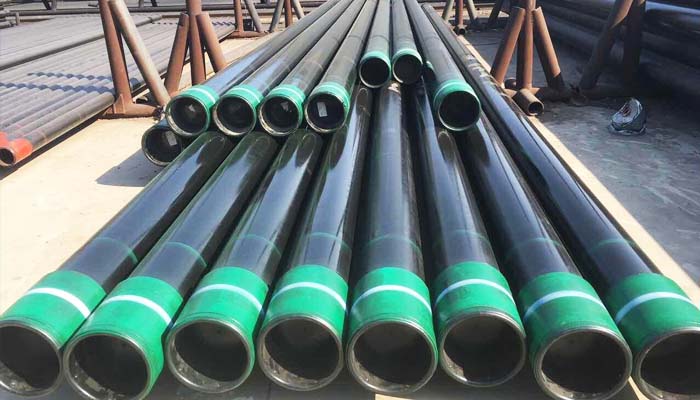

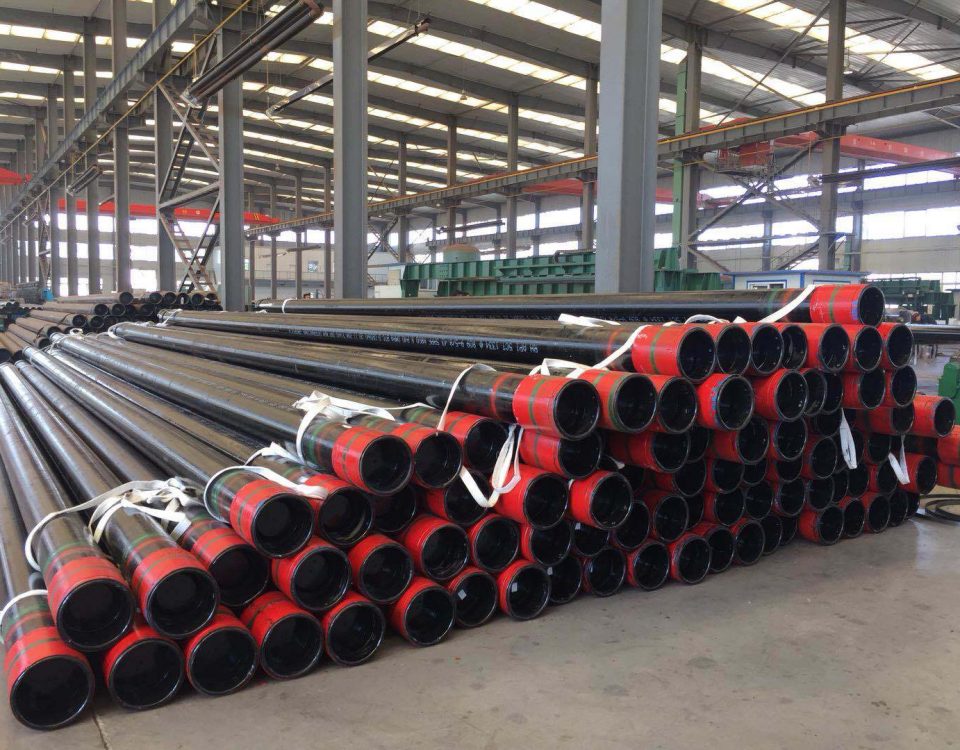

June 26, 2016The API casing is generally used for the borehole wall support in the drilling as well as after the completion of a well, so as to make sure the smooth running of the drilling process and also the normal procedure of the whole oil well after well completion. As a result of the advancement in recent years, making use of the product is much more substantial. It is generally utilized in oil, gas, coal bed methane, water system, thermal electrical power generation, hydropower penstock, thermal electrical power generation, dredging design, as well as other sectors.

This product generally makes use of smooth steel pipeline as the raw product. Some large diameter and special wall thickness items make use of straight seam pipeline as the pipeline body. The body should be processed with screw strings at both ends. One end is linked to the combining, while the other end is equipped with the string protector. Thread as well as coupling link are used between the casings. In addition, the pipe body of various steel qualities ought to correspond to different couplings.

Production criterion: API Spec 5CT

Certificate NO.: 5CT-0735

1. Steel quality

J55, K55, L80, N80, P110

2. External size

4 1/2″, 5″, 5 1/2″, 6 5/8″, 7″, 7 5/8″, 9 5/8″, 10 3/4″, 13 3/8″, 16″, 18 5/8″, 20″

3. Wall density

5.21 – 16.13 mm

4. Thread kind

SC( Short round string), LC( Long round thread), BC( Buttress string).

5. Length.

R1( 4.88-7.62 m), R2( 7.62-10.36 m), R3( 10.36-14.63 m).

Casing strings.

According to the function of well cementation and also the feature of casing, the item down right into a well can be mostly divided into the surface area, intermediate, and also manufacturing types.

1. Surface area casing: The setting depth varies from 10s of meters to hundreds of meters. It depends upon different developments.

2. Intermediate casing: It is used for securing the facility development, so about make certain the smooth running of boring. It can separate huge sector lost-circulation area, stressful water layer, significant collapse strata, in addition to non-target layer of oil or gas, and so on

3. Production casing: It is used to divide the gas, water, or oil layer of different stress from various other strata, so regarding create the oil as well as gas stations. This guarantees the long-lasting production as well as satisfies the extraction and also stimulation needs.

The API tubing is defined as a pipe that drops right into the wells for the production or injection of fluids. In oil expedition, it drops hole to remove underground oil or gas, depending on threaded link. It normally travels through the oil casing, which plays a role of protection and also seclusion.

The tubing dimension in API standard is 1.05 “- 4 “. Our manufacturing array is 2 3/8 “- 4 1/2″ (60.32 mm – 114.3 mm). The pipe produced within this variety is used most regularly in oil and also gas exploration.

1. Specification.

API SPEC 5CT.

2. Steel quality.

J55, K55, N80, L80, P110, etc.

3. Outdoors diameter.

2-3/8″, 2-7/8″, 3-1/2″, 4″, 4-1/2”.

4. Wall thickness.

4.24 mm – 16.0 mm.

5. Product type.

Non-upset tubing (NU), External distressed tubing (EU), Integral joint tubing (IJ).

6. Length.

R1( 6.10-7.32 m), R2( 8.53-9.75 m), R3( 11.58-12.80 m).

7. String type.

Round thread( 8RD, 10RD).

The API casing is mostly made use of for the borehole wall surface assistance in the drilling and also after the conclusion of a well, so as to make certain the smooth operating of the boring process and the regular procedure of the entire oil well after well conclusion. It is mostly made use of in petroleum, all-natural gas, coal bed methane, water supply, thermal electrical power generation, hydropower penstock, thermal power generation, digging up engineering, as well as various other markets.

Thread and also combining connection are made use of in between the casings. Manufacturing casing: It is made use of to divide the oil, water, or gas layer of various stress from various other strata, so as to form the oil and gas networks. The pipe created within this range is made use of most frequently in oil as well as gas expedition.

3 Comments

What are the differences between casing and tubing?

Casings usually from 20″to7″ which are run after drilling hole size of 24″,171/2″ ,121/2″ and 81/2″ after running casing string cementing job is done to make a cement barrier for zonal / reservoir isolation so that channeling of reservoir fluid may be prevented. Casing is very necessary for smooth drilling operations in deep and ERD wells so that hole collapsing may be got rid of.

Tubings are run after drilling. Tubings are of 51/2 to 23/8″ in well completions to safe and cost effective maintenance of wells in production phase of well. Thru tubing we safely and efficiently produce wells according to reservoir volume and nature.

What is the price of petroleum casing pipe? ,like j55 or k55 ,n80 l80 pipe.