API 5L Grade B ERW steel pipes diameter 426mm wall thickness 9.53mm

October 19, 2016

ASTM A252 SCH40 GR 2 OD 34 inch DRL seamless steel pipes

October 27, 2016The K55 API 5CT casing or tubing is extremely similar to the J55 type.

1. Warm treatment

PSL1 needs: J55 as well as K55 exact same way (can be rolled-state distribution); PSL2 needs: J55, K55 item should be normalized or stabilized and toughened up in general, if thick, ought to be stabilized or normalized and also solidified after thickened.

3. Impact test

J55 and also K55 influence test need to be done, the minimum size of the example side impact energy 20J, the tiniest full-size sample longitudinal effect energy 27J.

4. Wall density detection

PSL1: J55 as well as K55 on the tube did refrain from doing harmful testing compulsory needs;

PSL2: J55 and K55 for all pipe shall be one or more of the requirements defined in 10.15.5 evaluated to discover the inner surface area of the external surface area of the pipe as well as can receive the level of L4 longitudinal blemishes.

4.1 Size.

R1( 4.88-7.62 m), R2( 7.62-10.36 m), R3( 10.36-14.63 m).

5. NDT

The main steel quality of API 5CT:API 5CT J55, API 5CT K55, API 5CT N80, API 5CT L80, API 5CT P110.

This International Requirement applies to the following links based on ISO 10422 or API Specification 5B:.

short round string casing (STC);.

long rounded string casing (LC);.

strengthen string casing (BC);.

extreme-line casing (XC);.

non-upset tubes (NU);.

exterior distressed tubes (EU);.

integral joint tubes (IJ).

API 5CT K55 oil casing pipe contain fairly reduced steel grade, which resembles the J55 grade various other API 5CT common petroleum casing pipes.

It can be made both smooth and electrical welding procedure. J55 is available with warmth treatment approaches as complete product body or complete size of normalization, normalization plus tempering, or quenching plus tempering.

In the oil exploration, K55 API 5CT casing or tubes is a reasonably usual kind. Because of its low grade steel, it is primarily utilized for superficial oil and gas removal, particularly in gas and coal bed methane exploitation. It is additionally frequently utilized in shallow wells, geothermal wells, and water wells.

Specifications

1. External diameter

4 1/2″, 5″, 5 1/2″, 6 5/8″, 7″, 7 5/8″, 9 5/8″, 10 3/4″, 13 3/8″, 16″, 18 5/8″, 20″

2. Wall surface thickness

5.21 – 16.13 mm

3. String kind

SC( Short round string), LC( Lengthy round thread), BC( Buttress string).

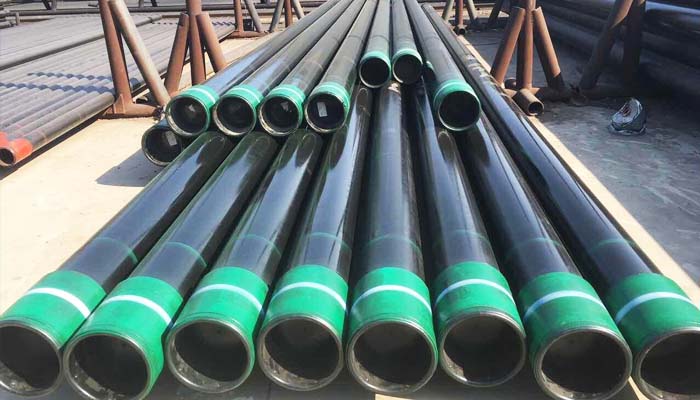

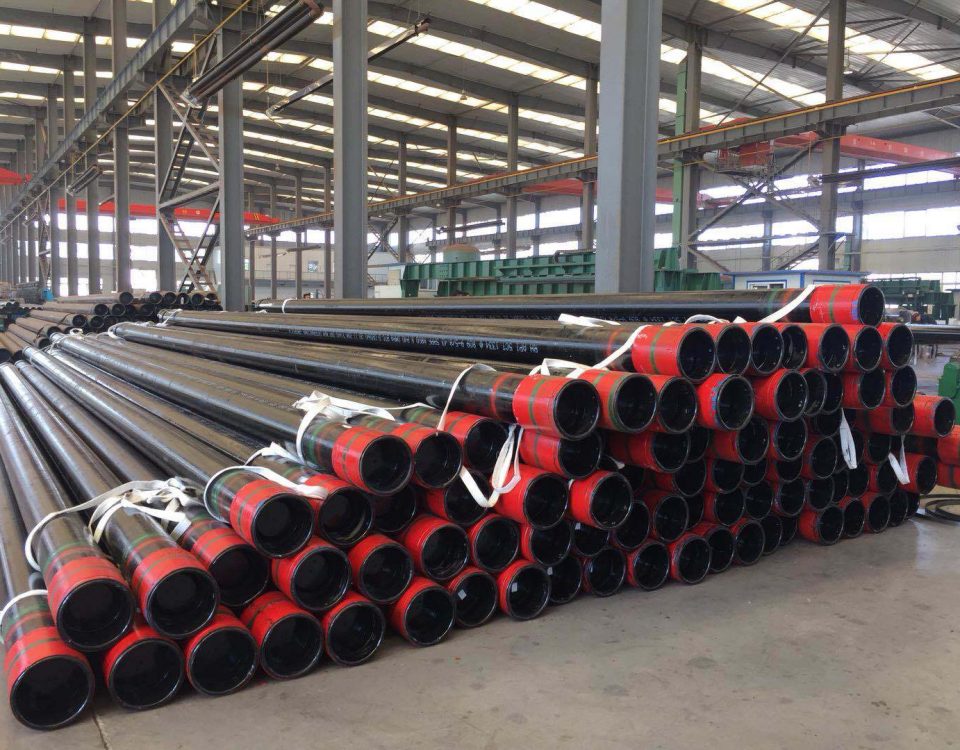

In the oil drilling, K55 API 5CT casing or tubing is a reasonably typical type. API 5CT K55 oil casing pipe has the sulfur and phosphorus components of specifically much less than 0.030%. Our item claims greater tensile toughness compared to the J55 kind. Exact same as J55 type product, there is likewise an environment-friendly bar splashed on our API 5CT K55 oil casing pipe. API 5CT K55 primarily offers to safeguard the wall of a well and also prevent the oil as well as gas from leak.

Like J55 type item, there is also an eco-friendly bar sprayed on our API 5CT K55 oil casing pipe. The difference is that the combining of J55 has an added white bar. API 5CT K55 mainly offers to protect the wall surface of a well and also protect against the oil and also gas from leak. Layer on its surface area supplies extra security versus the deterioration.

There is no distinction in the chemical structure and yield strength, however the tensile strength of K55 is higher than J55 steel. In actual sales, the rate of theses two materials is basically remained the same, and the purpose is very close.

API 5CT K55 oil casing pipe includes the sulfur as well as phosphorus contents of respectively much less than 0.030%. Its chemical as well as physical homes are basically much like J55. Our product declares greater tensile strength compared to the J55 kind. The minimum worth is 95ksi.

2 Comments

can you explain the difference of casing pipe and tube?

The main difference in between pipe and tubing is how the size is designated. Pipe is designated by a “Nominal Pipe Size” based upon the ID (inside size) of the most common wall density. Tubing is designated by the measured OD (outdoors size). For instance: A 3/4 inch iron pipe has an OD of 1.050 inches, while a 3/4 inch steel tube has an OD of 0.75 inches.

Housing is used a protective methods, such as tunnel housing, to secure the procedure pipe or other mechanical equipment, and so on. Tubing is normally thin walled as in boiler and condenser tubes to enhance heat transfer. Tubing can likewise refer to smaller diameters such as instrument tubing for various chemical gases.

tubes and pipes both used to carry fluid, oil, and so on

and casing is done to cover pipelines, tubes.

typically a typical pipe can be cut into half( Vertically) and be fixed as an external housing