comparation of carbon steel pipes and black pipes

October 17, 2016

K55 VS J55 CASING PIPE

October 23, 2016Chemical Requirements for API 5L steel pipe

API 5L Specifications covers seamless and welded pipe suitable for use in conveying gas, water, oil, and other melted media. The affixed requirements cover our offering of API 5L 45th Ed, PSL 1 Seamless and Welded; API 5L 45th Ed PSL 2 Seamless & Welded; and API 5L 45th Ed PSL2 Welded just.

Tensile Properties for seamless and bonded API 5L steel pipe

Abter steel Products tensile homes information for seamless and welded API 5L steel pipe API 5L 45th Ed PSL 1, PSL 2.

Checking Requirements for seamless and bonded API 5L steel pipe

Abter steel Products hydrostatic and mechanical screening information for all grades and sizes covered by the spec.

Acceptable Variations for seamless and bonded API 5L steel pipe

Marking Requirements

Paint-stenciled or die-stamped manufacturer’s name or mark, Spec 5L, size, weight per foot, grade, procedure of manufacture, kind of steel, length (NPS 4 and larger only). Test pressure when greater than arranged (NPS 2 and larger only).

Supplemental Annexes for API 5L seamless and welded steel pipe

API Specification 5L contains 15 Supplemental Annexes that deal with extra requirements and/or special conditions.

Grade for API 5L steel pipes: GR A, GR B, X42, X46, X52, X56, X60, X65, X70, X80

api 5l erw pipe

specification for API 5L Grade B ERW steel tubes diameter 426mm wall thickness 9.53mm

| Product Name | API 5L Grade B ERW steel pipes diameter 426mm wall thickness 9.53mm |

| ERW Steel pipe Diameter | 426mm |

| Diameter Tolerance | 423.87mm ~ 428.13mm (acc. To API 5L,+/-5% but max. 1.6mm) |

| Wall Thickness of ERW Steel pipe | 9.53mm or other wall thckness required |

| Wall Thickness Tolerance | 8.58mm ~10.48mm (acc. to API 5L, +/- 10% t) |

| ERW Steel Tube Length | SRL, DRL, Random length from 3m to 18m |

| Pipe Standard | API 5L, CSA Z245, ASTM A53, A106, ASTM A252, AS 1163, IPS 190 etc |

Test for API 5L Grade B ERW steel pipes OD426

Hydro test, UT test, Flatten test, Impact test, Tensile test, Yield Test, DWT test if concurred and so on

application of API 5L Grade B ERW steel pipes OD426

Line pipe, fluid pipe, pipes, structure steel tube, stacking tube, stacking pipe.

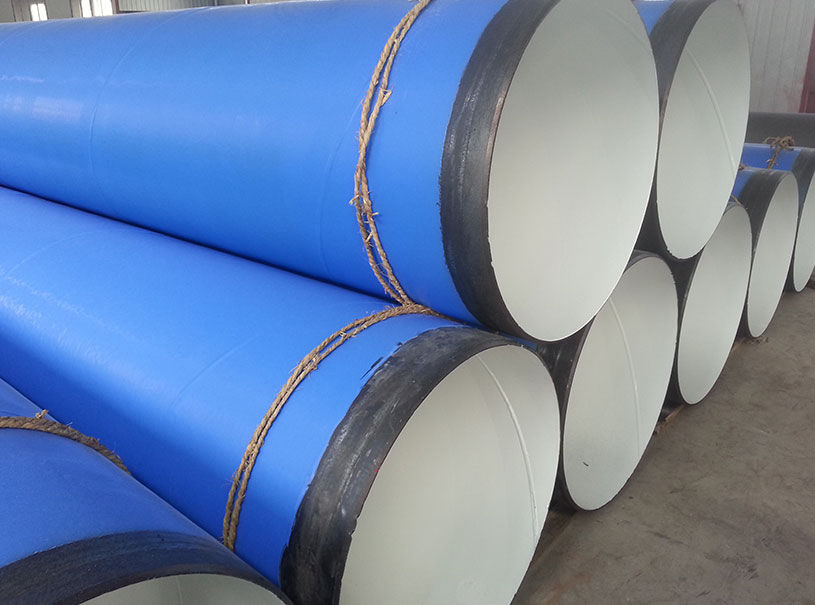

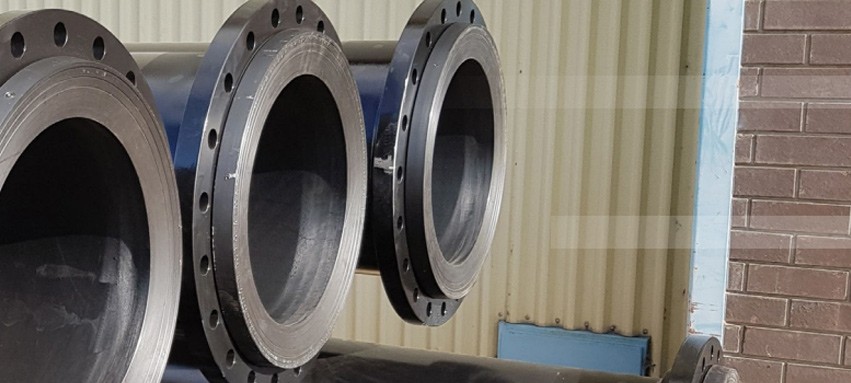

coatings of API 5L Grade B ERW steel pipes OD426

Black painting, varnish, anti rust oil, FBE,3 PE, 3 layer PE, 3PP and so on

Inspections for API 5L Grade B ERW steel pipes OD426

ISO9001, SGS, BV, GL, Moody or other TPI inning accordance with client’s requirement.

API 5L ERW pipe line capacity:

10000 metric tons monthly.

Packaging API 5L ERW pipe line

API 5L ERW line pipe are separately wrapped by hand to guarantee that the high quality of the material is kept and no damage in the last phases of production. We recommend Plywood cases or pallet packaging to make sure safe packaging and timely delivery of the bought consignment.

API 5L ERW line pipe come with imprints pertinent to the job info (eg, heat number, product, size and part number). This information is likewise printed along all delivered API 5L ERW line pipe.

Payment term for API 5L ERW pipe line:

TT(30% of total money for deposit) or 100% Lc at sight

2 Comments

I want to use API 5L Gr.B Seamless instead of ASTM A106 Gr.B. Please tell me detail for this replacements?

Merely API 5l Gr B accredited pipe can not be used in place of SA 106 Gr B in a pressure vessel or o heat exchanger developed to ASME and specifically U stamp task, Particularly if it is going to United States. If the job is going to be some where in Pakistan then you could be using ASME sec VIII as style requirement and this might not have the force of LAW, for this reason usage of API 5l Gr B in place of A 106 Gr B is based on your engineering judgement (Fitness of purpose) in most of the less crucial services this substitution would do no harm however once again you need to choose which is important and which is not.

The allowed stress for API 5L is given up ANSI B 31.3. You might jolly well substitute the grades in Pressure plant piping.

As it has been explained multiply significant pipes are acceptable for use in ASME exchangers and vessels.

Nevertheless there are some prominent difference between API 5L gr B and SA 106 Gr B. Compare the chemistry which have to be reported in case of API and A 106. Likewise API pipes are bought to OD (From the year 2000) where as SA 106 are ordered to NPS.