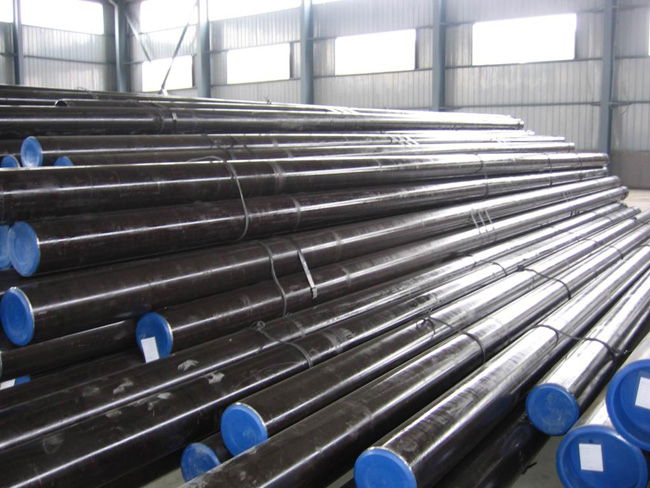

seamless steel pipes and welding (ERW) tubes/SMLS pipelines

October 14, 2016

API 5L Grade B ERW steel pipes diameter 426mm wall thickness 9.53mm

October 19, 2016what is black pipe?

Black steel pipe is the uncoated steel and is likewise called as black steel. The dark color originates from the iron-oxide formed on its surface during manufacturing. When steel pipe is forged, a black oxide scale types on its surface area to give it the finish which is seen on this type of pipe.

Black pipelines are used to bring water and gas from their sources to the end users. It is the pipe that is used by houses and businesses to convey their supply of natural or propane gas.

Due to the fact that of its strong resistance to heat, it is also used for fire sprinkler systems. Cooling and heating water moved to heat exchangers likewise utilize black pipe. It is generally signed up with by welding or by utilizing mechanical couplings.

Black carbon steel is typically used for gas or water energy piping, due to the fact that it has low expense and can be bonded using common approaches. Some long-distance oil pipelines have actually utilized black carbon steel piping, since the pipe can be connected in the field and will not rust quickly.

A lot of black steel pipe has a structure comparable to ASTM A-53 pipe. The distinction between A-53 and typical steel pipe like A-106 are so close that some pipe is in fact marked to fulfill both specs. Black pipe and A 53 can be smooth or bonded joint while A106 is smooth.

Black steel pipe is cast from numerous grades of ductile or flexible iron, whereas carbon steel pipe is normally wrought bonded or smooth. Black steel pipe is utilized for underground or submerged applications and for primary steam pipes and branches that undergo acids. It was likewise common to utilize cast iron pipe and fittings for local cold water lines 4 ″ diameter and above. Industrial die casting disagrees for lines subjected to growth strains, contractions, and vibration unless the pipe is really heavy. It is not suitable for super heated steam or for temperatures above 575 degrees F. Cast iron pipe in underground applications (such as sewage system lines) generally has bell and spigot ends whereas exposed pipe generally has actually flanged ends.

black pipe

what is carbon steel pipes?

carbon steel pipe is generally wrought welded or seamless. It was also common to use cast iron pipe and fittings for municipal cold water lines 4″ diameter and above. Commercial die casting is unsuitable for lines subjected to expansion strains, contractions, and vibration unless the pipe is very heavy. It is not suitable for superheated steam or for temperatures above 575 degrees F. Cast iron pipe in underground applications (such as sewer lines) usually has bell and spigot ends whereas exposed pipe usually has flanged ends.

steel whose characteristics are determined by the amount of carbon it contains. And steel is considered to be carbon steel when no minimum content is specified or required for chromium, cobalt, niobium, molybdenum, nickel, titanium, tungsten, vanadium or zirconium, or any other element to be added to obtain a desired alloying effect; when the specified minimum for copper does not exceed 0.40 percent; or when the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65, silicon 0.60, copper 0.60.

Most the steel produced in the world falls into the category of carbon steel.

Carbon steel pipe starts by coming to the pipe mill through either a billet (essentially a large strong steel bar) or a coil (envision a roll of toilet paper made out of steel). Depending on the production technique used by the mill, these billets or coils will be processed to yield the completed final product. We will examine the various manufacturing techniques used to make carbon steel pipe, but first let’s take a look at how the carbon steel got here in the very first place.

Carbon steel depends mainly on carbon to form the durable alloy. Carbon steel may contain other agents such as manganese, cobalt, or tungsten, but the proportion of these materials is not specified. The following shows the four types of carbon steel:

- Mild / low – contain very low percentages of carbon

- Medium – 0.3 to 0.59% carbon by weight

- High – 0.6 to 0.99% carbon

- Ultra high – 1.0 to 2.0% carbon

carbon steel pipe

characteristics of carbon steel pipes:

1. Safe and Durable

Since it is resilient and safe, steel is frequently used. Building materials underground might be prone to decomposing and insects. Steel will not rot and is resistant to insects like termites. Steel likewise does not require to be treated with preservatives, pesticides or glue, so it is safe to deal with and work around. Since steel is non-combustible and makes it harder for fire to spread, it is great to utilize when building homes. Steel frame buildings are more resistant to natural catastrophes like tornados, cyclones, lightning strikes, and earthquakes.

Carbon steel pipe is extremely resistant to shock and vibration. Carbon steel pipe is almost unbreakable in transportation and service, and for this reason it is alright to lay water mains under streets.

The high tensile strength of steel in addition to its elasticity and ductility permit pipelines to be utilized safely for really high pressures. A carbon steel pipe can be made much thinner than pipelines made from other products, so they have a greater carrying capacity than pipelines of other products with the exact same diameter.

2. Eco-friendly

Utilizing steel for pipes is not just much safer for people, but it is safer for the earth. Producing steel has likewise gone green; almost half the world’s steel is produced in electric plants that utilize recycled scraps and create no CO2 emissions.

3. Affordable

For any offered pressure, carbon steel pipes can be made much thinner than pipelines made from other products, so they have a higher carrying capacity than pipes of other materials with the exact same diameter. Carbon pipe suppliers understand that their steel pipelines are cheaper than copper pipes. The unrivaled strength of steel piping increases durability and reduces the requirement for replacement and repair works.

Its versatility likewise makes it cost-effective. Carbon pipe providers can make pipes in lots of measurements, from less than an inch to over 5 feet.

Carbon steel pipe is highly resistant to shock and vibration. Carbon steel pipe is almost solid in transportation and service, and for this factor it is fine to lay water mains under roads.

Producing steel has likewise gone green; practically half the world’s steel is produced in electric plants that use recycled scraps and create no CO2 emissions. For any given pressure, carbon steel pipelines can be made much thinner than pipes made from other products, so they have a higher carrying capability than pipelines of other products with the very same size. Carbon pipe providers know that their steel pipes are less expensive than copper pipes.

Difference in outlooking

The primary purpose of black steel pipe is to bring gas or natural gas into commercial buildings and domestic homes. The pipe is manufactured without a seam, making it a better pipe to bring gas. Because it is more fireproof than galvanized pipe, the black steel pipe is also used for fire sprinkler systems. The main usage of galvanized pipe is to carry water to homes and commercial buildings. The zinc likewise prevents the buildup of mineral deposits that can block the water line. Due to the fact that of its resistance to corrosion, galvanized pipe is commonly used as scaffolding frames.

Distinction in problems

The zinc on galvanized pipe flakes off over time, obstructing the pipe. Black steel pipe, on the other hand, wears away more quickly than galvanized pipe and permits minerals from water to construct up inside it.

3 Comments

What is carbon steel?

How many kinds of carbon steel pipes are they? Its manufacturing process is what?

Production of steel pipe is grouped into two general categories: WELDED steel pipe and SEAMLESS steel pipe .

There are many methods of producing steel pipe in current use. However, most of the pipe produced in the china abter steel is made by either the Continuous Weld, the Electric Resistance Weld (ERW PIPE ), the Double Submerged Arc Weld (DSAW PIPE )or the Seamless method(SEAMLESS STEEL PIPE).