differences between N-80 and L-80 Casing Pipe

November 7, 2016

ASTM A106, Gr.B seamless steel pipe,SCH40,OD 355.6mm, WT11.13mm

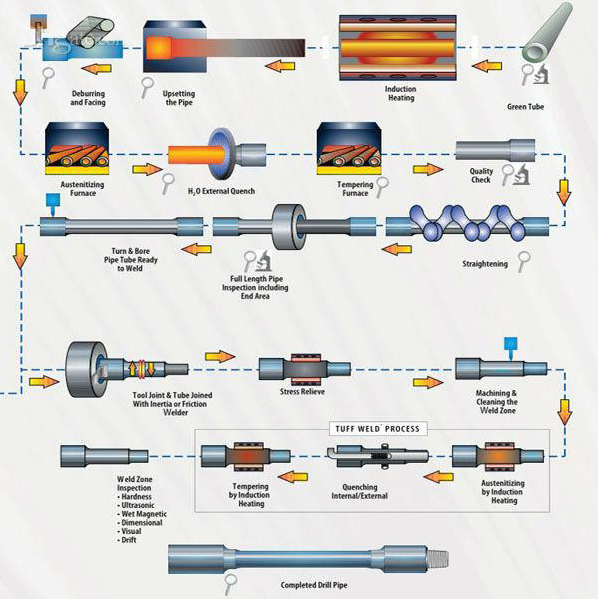

November 14, 2016Drill pipe is hollow, thick-walled piping that transfers drilling fluid and torque through the wellbore to the drill bit on a drilling rig. It is made to endure serious internal and external pressure, distortion, bending, and vibration as it both rotates and lifts the bottom hole assembly (BHA). Drill pipe is threaded on each end in a section of pipe described as the tool joint. It is manufactured, sampled, tested, and inspected in accordance with basic specs such as the American Petroleum Institute (API).

Drill pipe Grade: E75, X95, G105, S135 .

The wear-resistant belt of tool joint: Arnco 100XT, 200XT, 300XT, 400XT

Internal coating drill pipe: TK34, DPC, TC2000, TC3000

Drill pipe

drillpipeprocess

API SPEC 5DP defines the technical delivery conditions for steel drill-pipes with upset pipe-body ends and weld-on tool joints for usage in drilling and production operations in petroleum and natural gas industries for 3 product requirements levels (PSL-1, psl-3 and psl-2). PS-1 defines wall thickness, impact strength, and yield strength requirements particular to the material grade. Requirements levels PL-2/ PL-3 have extra obligatory requirements.

| API Drill Pipe Grade | Minimum Yield Strength (psi) | Minimum Tensile Strength (psi) |

| E-75 | 75,000 | 100,000 |

| X-95 | 95,000 | 105,000 |

| G-105 | 105,000 | 115,000 |

| S-135 | 135,000 | 145,000 |

detailed information about API SPEC 5DP Drill pipe

|

Size Inch |

Nominal Weight |

Weight c/w blank end |

OD |

Wall Thickness |

Grade |

Upset Type |

|||

| lb/ft | Kg/m | inch | mm | inch | mm | ||||

| 2-3/8 | 6.65 | 6.27 | 9.33 | 2.375 | 60.3 | 0.280 | 7.11 | E,X,G,S | EU |

| 2-7/8 | 10.4 | 9.72 | 14.47 | 2.875 | 73.0 | 0.362 | 9.19 | E,X,G,S | EU |

| 3-1/2 | 13.3 | 12.32 | 18.34 | 3.500 | 88.9 | 0.368 | 9.35 | E,X,G,S | EU |

| 3-1/2 | 15.5 | 14.64 | 21.79 | 3.500 | 88.9 | 0.449 | 11.4 | E,X,G,S | EU |

| 4 | 14.0 | 12.95 | 19.27 | 4.000 | 101.6 | 0.330 | 8.38 | E,X,G,S | IU, EU |

| 4-1/2 | 16.6 | 15.00 | 22.32 | 4.500 | 114.3 | 0.337 | 8.56 | E,X,G,S | EU, IEU |

| 4-1/2 | 20.0 | 18.71 | 27.84 | 4.500 | 114.3 | 0.430 | 10.92 | E,X,G,S | EU, IEU |

| 5 | 19.5 | 17.95 | 26.70 | 5.000 | 127.0 | 0.362 | 9.19 | E,X,G,S | IEU |

| 5 | 25.6 | 24.05 | 35.80 | 5.000 | 127.0 | 0.500 | 12.7 | E,X,G,S | IEU |

| 5-1/2 | 21.9 | 19.83 | 29.52 | 5.500 | 139.7 | 0.361 | 9.17 | E,X,G,S | IEU |

| 5-1/2 | 24.7 | 22.56 | 33.57 | 5.500 | 139.7 | 0.415 | 10.54 | E,X,G,S | IEU |

| 6 5/8 | 25.2 | 22.2 | 33.04 | 6.625 | 168.275 | 0.330 | 8.38 | E,X,G,S | IEU |

| 6 5/8 | 27.7 | 24.23 | 36.05 | 6.625 | 168.275 | 0.362 | 9.19 | E,X,G,S | IEU |

(note:IU – In an internal upset increased thickness along the inside walls compensate for the metal removed in threading with a uniform, straight outside wall.

EU – In an external upset the increased thickness along the outside diameter of the tubing compensates for the metal removed in threading with a straight bore.

IEU – In an internal-external upset thickness is increased along both the inside and outside walls of the pipe to compensate for the metal removed in threading.)

Grade E drill pipe, described as “mild” steel, shows the most affordable yield strength per system location with a yield strength of less than 80,000 psi. It has the ability to endure a greater portion of stretch or “pressure” prior to fracture than higher strength drill pipe grades. It is likewise more resistant to corrosion and cracking. Grade E is used in medium depth wells from 10,000 to 15,000 feet.

Grades X-95, G-105, and S-135 are thought about high strength grades. They exhibit increased yield strength which is needed to service deeper wells.

Usage of API 5DP drill pipe: Mine blasting, water well drilling, geothermal wells drilling, fore poling, coal and nonferrous metal mining projects, etc.