high quality API 5CT casing and tubing for oil and gas drillings

February 14, 2017

High precision ASTM A53 carbon seamless steel pipe for gas and oil

February 17, 2017API ERW Carbon Steel Pipes

Standard related to Grade:

| No. | Name | Standard | Grades | Application |

| 1 | Casing Pipes | API 5CT | H40,K55, N80-1,J55 |

For oil-gas well casing |

| 2 | Line Pipes | API 5L | A, B–X70 L210–L485 |

For the pipeline transportation of oil and natural gas |

| 3 | Welded Steel Tubes

For Pressure Purposes |

EN10217-1 | P195TR1 P195TR2 P235TR1 P235TR2 P265TR1 P265TR2 |

Welded Steel Tubes For Pressure Purposes |

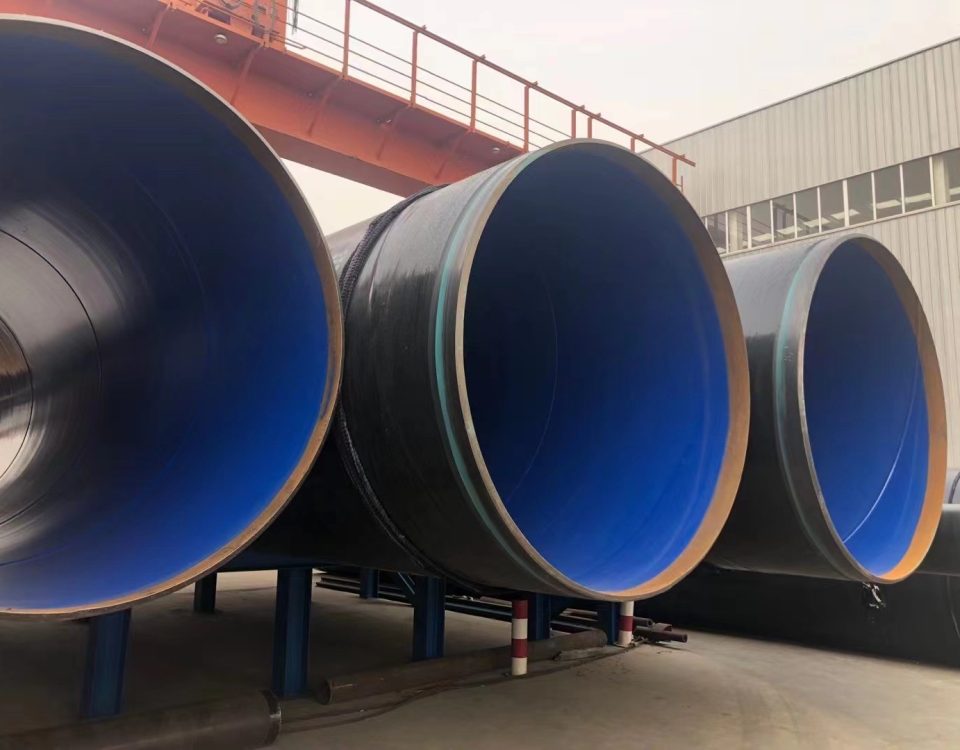

Surface: Lightly oiled, Hot dip galvanized, Electro galvanized, Black, Bare, Varnish coating/Anti rust oil, Protective Coatings (Coal Tar Epoxy ,Fusion Bond Epoxy, 3-layers PE)

Chemical Analysis(%):

| Type of pipe | Class | Grade | C | Si | Mn | P | S | V | Nb | Ti |

| max | max | max | max | max | max | max | max | |||

| Welded | PSL1 | L245 B | 0.26 | – | 1.2 | – | 0.03 | 0.03 | – | – |

| L290 X42 | 0.26 | – | 1.2 | – | 0.03 | 0.03 | – | – | ||

| L320 X46 | 0.26 | – | 1.2 | – | 0.03 | 0.03 | – | – | ||

| L360 X52 | 0.26 | – | 1.2 | – | 0.03 | 0.03 | – | – | ||

| L390 X56 | 0.26 | – | 1.2 | – | 0.03 | 0.03 | – | – | ||

| L415 X60 | 0.26 | – | 1.2 | – | 0.03 | 0.03 | – | – | ||

| L450 X65 | 0.26 | – | 1.2 | – | 0.03 | 0.03 | – | – | ||

| L485 X70 | 0.26 | – | 1.2 | – | 0.03 | 0.03 | – | – | ||

| PSL2 | L245M BM | 0.22 | 0.45 | 1.2 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | |

| L290M X42M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | ||

| L320M X46M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | ||

| L360M X52M | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | – | – | – | ||

| L390M X56M | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | – | – | – | ||

| L415M X60M | 0.22 | 0.45 | 1.6 | 0.025 | 0.015 | – | – | – | ||

| L450M X65M | 0.22 | 0.45 | 1.6 | 0.025 | 0.015 | – | – | – | ||

| L485M X70M | 0.22 | 0.45 | 1.7 | 0.025 | 0.015 | – | – | – | ||

| L555M X80M | 0.22 | 0.45 | 1.85 | 0.025 | 0.015 | – | – | – |

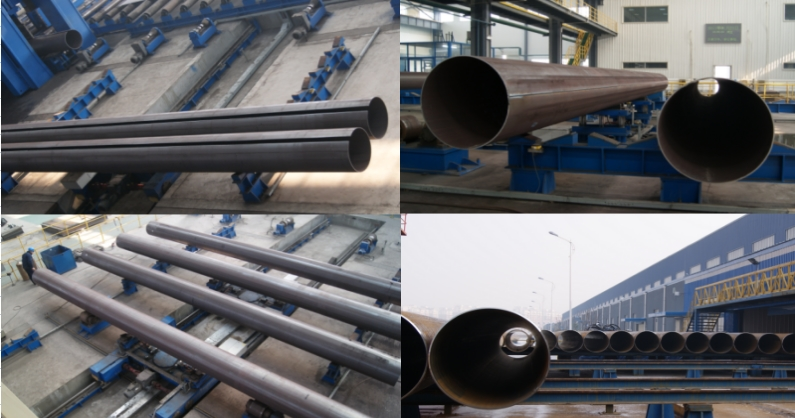

Warehouse and Stock Indoor:

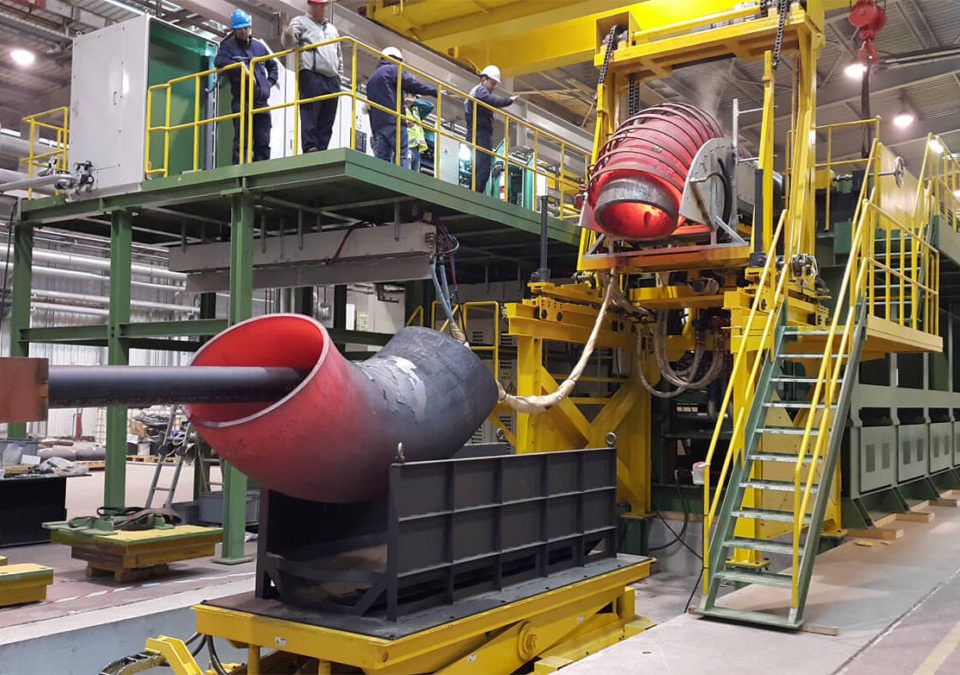

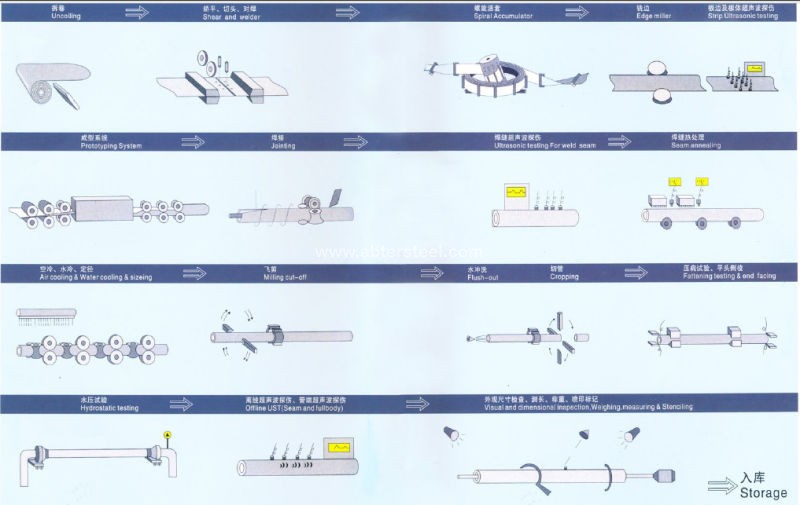

Manufacture Process:

| Type of pipes | Similar specification | |||||

| Type | Manufacturing

method |

Korea | Japan | U.S.A | U.K/

Others |

Application |

| ERW | Carbon steel pipes for ordinary piping (KS D 3507/SPP) | Carbon steel pipes for ordinary piping (JISG 3452/SGP) | ASTM A53 | BS 1387 EN10255 IS065 | Steel pipes for steam, air, water, oil and gas etc. with relatively low pressure | |

| ERW | Galvanized steel pipes for water service (KS D 3537/SPPW) | Galvanized steel pipes for v\/at6「service (JISG 3442/SGPW) | ASTM A53 | BS 1387 EN10255 IS065 | Steel pipes for water supply with 100m or less at water head | |

| Steel pipes for ordinary piping | ERW

Spiral Roll bending |

Coated steel pipes for water works

(KS D 3565/STWW) Fittings of coated steel pipes for water works (KS D 3578) |

– | AWWA C200, C203 | – | Steel pipes for water works |

| Spiral

Roll bending |

Arc welded carbon steel pipes (KS D 358B/SPW) | Arc welded carbon steel pipes (JISG 3457/STPY) | ASTM A 134,

A139,A671, A672 |

– | Steel pipes for steam, air, water, oil and gas etc. With relatively low pressure | |

| Steel pipes for pressure service | ERW and SAW | Carbon steel pipes for pressure service (KS D 3562/SPPS) | Carbon steel pipes for pressure service (JISG 3454/STPG) | ASTM A53 API 5L | BS 3601

EN10217-1 ISO9330-1 |

Steel pipes for application at a temperature of 350° C or less |

| Roll bending | Arc welded carbon steel pipes (KS D 358B/SPW) | Arc welded carbon steel pipes (JISG 3457/STPY) | – | – | Piping for steam, water, gas, air of comparatively low working pressure. | |

| ERW | Carbon steel tubes for machine structural purposes (KSD3517/STKM) | Carbon steel tubes for machine structural purposes (JISG 3445/STKM) | ASTM A513 | BS 980 BS 1717 BS 1775 | Steel pipes for application for mechanical Parts such as machinery, automobiles, bicycles, furniture and fixtures etc. | |

| Steel pipes for

structural purposes |

ERW

Spiral Roll bending |

Caron steel tubes for machine structural purposes (KS D 3566/STK) | Carbon steel tubes for general structural purposes (JIS G 3444/STK) | ASTM A500 | BS 980 BS 1139 BS 4848 | Steel pipes for application for structures such as civil works, architecture, steel tower, scaffolding, piles, veranda and fence and post etc. |

| ERW | Carbon steel square pipes for general structural purposes (KS D 3568/SPSR) | Carbon steel square pipes for general structural purposes (JIS G 3466/STKR) | ASTM A500 | BS 4848 | Steel pipes for application tocivil works, architecture and other stuctures | |

| ERW

Roll bendinq |

Steel pipe piles (KS F 4602) | Steel pipe piles (JISA 5525/SKK) | ASTM A252 | – | Steel pipes for foundation civil works, architectures etc. | |

| Spiral

Roll bending |

– | – | Fubrication of structural steel pipe (API 2B) | – | Offshore structure.

Piping and main structural members |

|

| Line

pipe |

ERW

Roll bending |

– | – | API 5L (GR, A, B, X42, X46, X52, X56, X60, X65, X70, X80) | – | Steel pipes for transportation petroleum and natural gas |

| OCTG | ERW | – | – | API 5CT (H40, J55, K55, N80) | – | Steel pipes for development for petroleum and natural gas |

| Conduits | ERW | Rigid steel conduits (KSC 8401) | Rigid steel conduits (JIS C 8305) | ANSI C80.1 UL6 | BS 31 | Steel pipes for protection of electric cable at electric distribution lines |

| Steel tubes for boiler & heat exchanger | ERW | Carbon steel boiler and heat exchanger tubes (KS D 3563/STBH) | Carbon steel boiler and heat exchanger tubes (JISG 3461/STB) | ASTM A 178, A 214, A 226 | BS 3059 BS 3606 | Water pipes for boiler, connection pipe, overheat engine, air preheating pipe and heat exchange pipes, condenser |

| Coated steel pipes | ERW

Spiral Roll bending |

– | – | – | – | Coated steel pipes for protection of outside surface of steel pipe for underground burial. |

| Steel tubes for tower structural purposes | ERW

Spiral Roll bending |

– | – | – | – | High tensile steel pipes applicable to electric transmission tower |