What are some common types of materials used for elbows in piping systems?

July 19, 2023

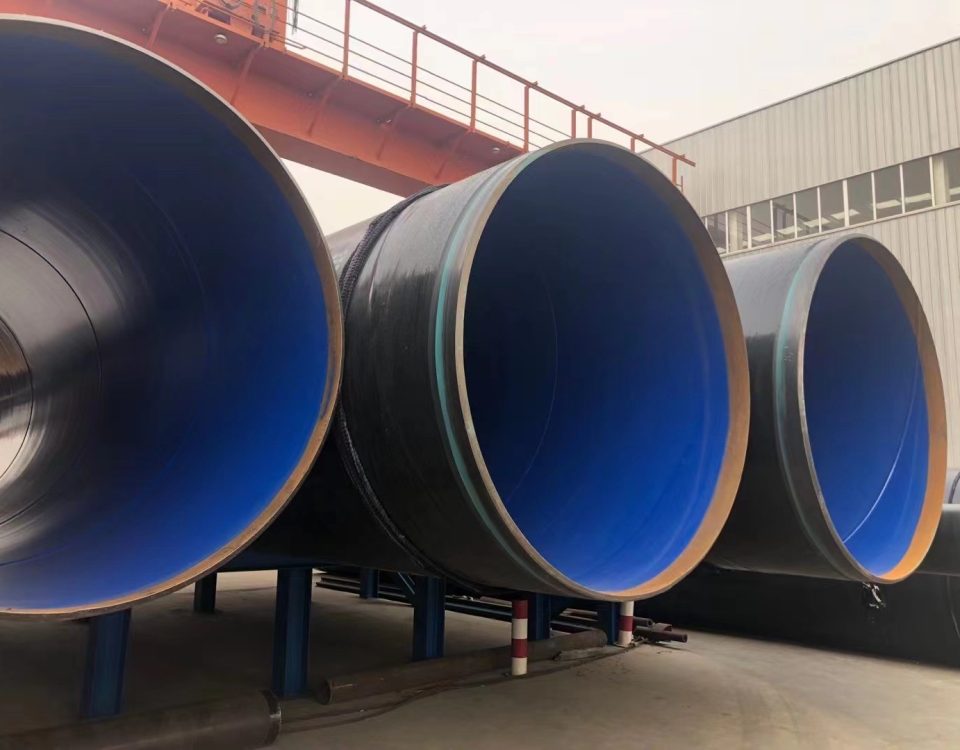

FBE | 2PE | 3LPE | Anti corrosion coating steel pipe

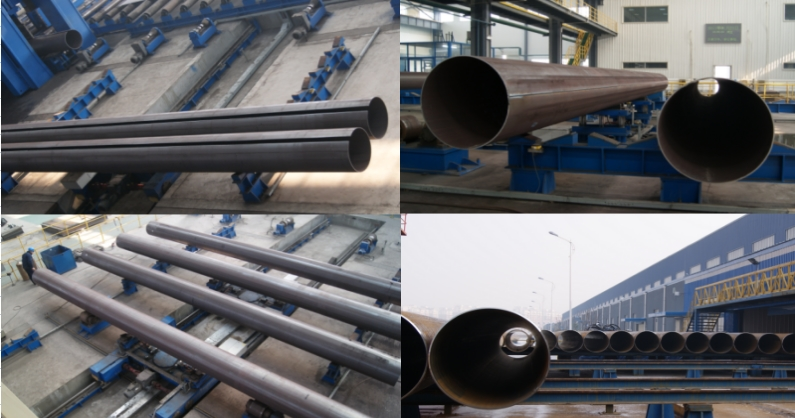

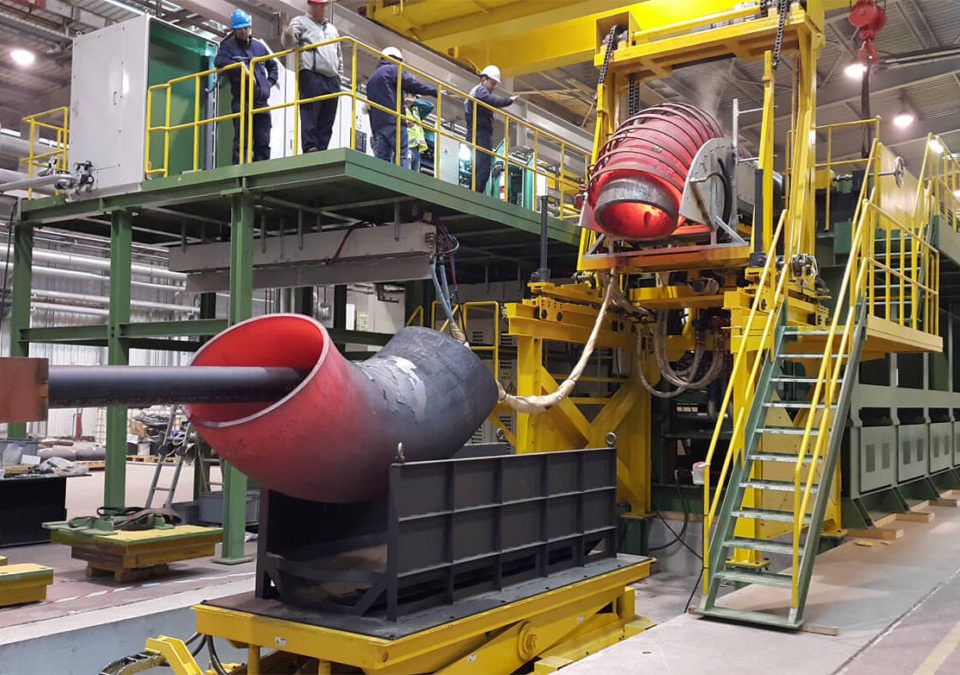

July 19, 2023SSAW (Spiral Submerged Arc Welding), LSAW (Longitudinally Submerged Arc Welding), and ERW (Electric Resistance Welded) are all methods of producing steel pipes. They each have their own distinct characteristics, advantages, and disadvantages:

- SSAW (Spiral Submerged Arc Welding) Steel Pipes:

- The SSAW pipe is produced by spiral submerged arc welding. This involves winding steel plates around a pipe mold and then welding the seam.

- The pipe has a spiral weld seam, which is visible externally.

- SSAW pipes can be produced in longer lengths and in large diameters.

- They are often used in applications like oil and gas transportation, water supply, construction, and piling projects.

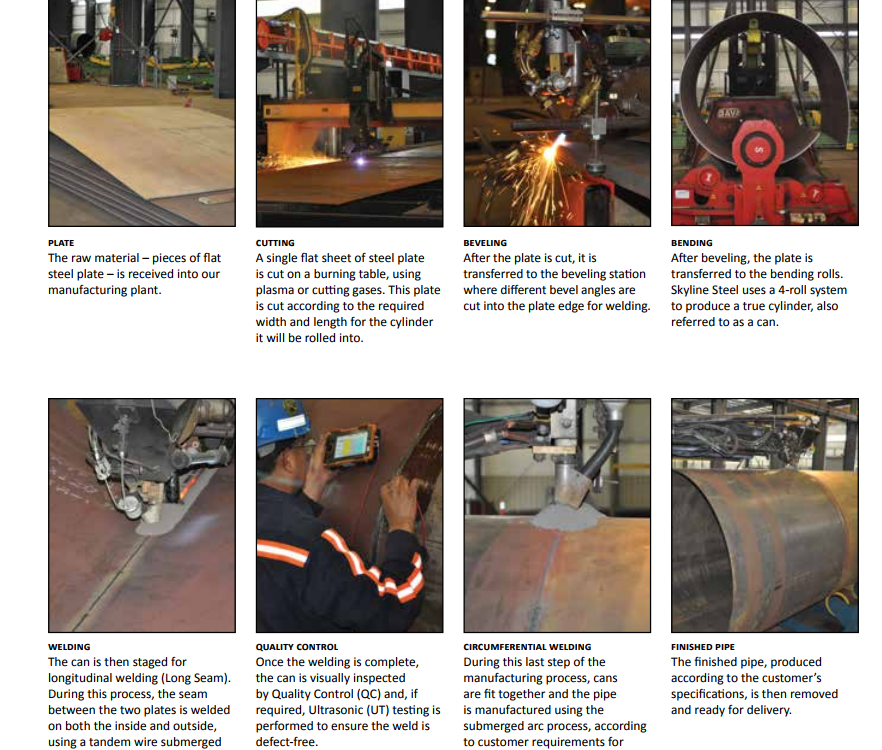

- LSAW (Longitudinally Submerged Arc Welding) Steel Pipes:

- The LSAW pipe is produced by longitudinally submerged arc welding.

- It involves welding a single sheet of steel longitudinally (lengthwise), resulting in a straight, longitudinal weld seam.

- LSAW pipes are often used in high-pressure applications because of their strength along the length of the pipe.

- They are typically used in oil and gas transportation, low-pressure fluid transmission, and structural applications.

- ERW (Electric Resistance Welded) Steel Pipes:

- ERW pipes are produced by electric resistance welding. This involves applying a high-frequency electric current to the edges of the steel plates, which heats them to the point of joining.

- The process doesn’t require filler material and results in a clean, efficient weld seam.

- ERW pipes are typically used in low to medium pressure applications. They are commonly used in the oil and gas industry, as well as in water, sewage, and structural applications.

Each of these types of pipes has its own strengths and weaknesses, and the choice between them will depend on the specific requirements of the application. It’s always best to consult with a professional engineer or metallurgist when selecting the type of pipe for a specific project.

How do the costs of these different types of pipes compare?

As of my knowledge cutoff in September 2021, precise cost comparisons of SSAW, LSAW, and ERW steel pipes are challenging to provide without specific details about pipe diameter, wall thickness, material grade, quantity, shipping, and other factors that can significantly influence the price. Costs can also vary based on regional availability, supplier relationships, and market fluctuations.

That being said, here are some general trends:

ERW pipes tend to be the most cost-effective of the three, largely because the Electric Resistance Welding process is relatively straightforward and efficient, and the pipes can be produced in long, continuous lengths.

SSAW pipes are typically more expensive than ERW pipes but less expensive than LSAW pipes. The spiral submerged arc welding process is a bit more complex than ERW, but it allows for larger diameters and longer lengths, which can offset some of the cost.

LSAW pipes are often the most expensive of the three. The longitudinally submerged arc welding process is complex and time-consuming, and LSAW pipes often require more material to produce than ERW or SSAW pipes. However, they are also stronger and more durable, which can make them a cost-effective choice for high-pressure applications.

Please keep in mind that these are general trends and actual costs can vary. Always request quotes from multiple suppliers to get the most accurate pricing information for your specific project. And remember that the cost may have changed after my last update in September 2021.