Basic knowledge of steel pipe varieties and standards

April 6, 2022

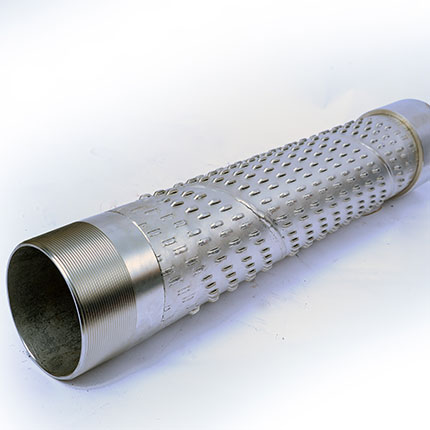

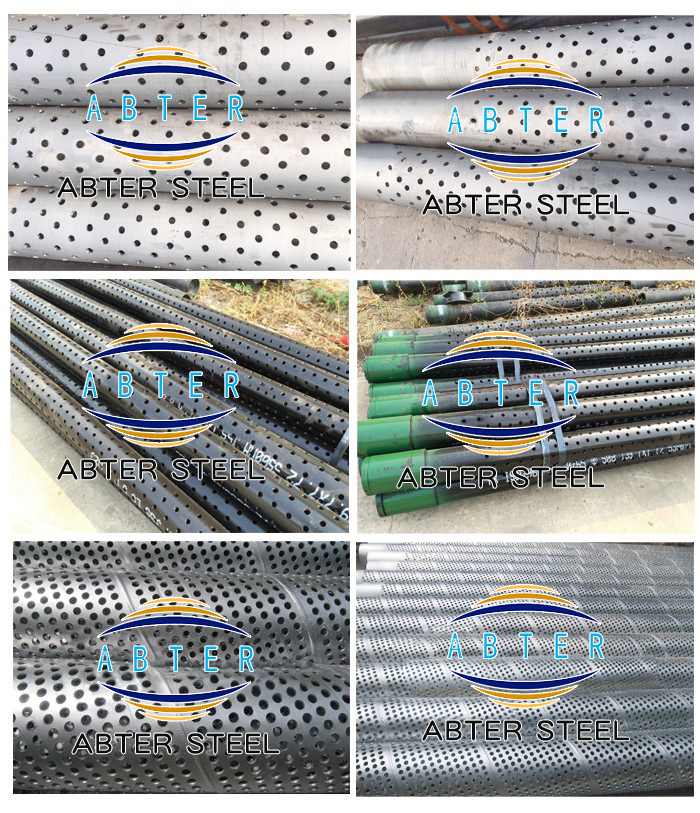

Hole-drilled pipe&Water filter pipe for geothermal well&Water filter pipe of air-conditioning well

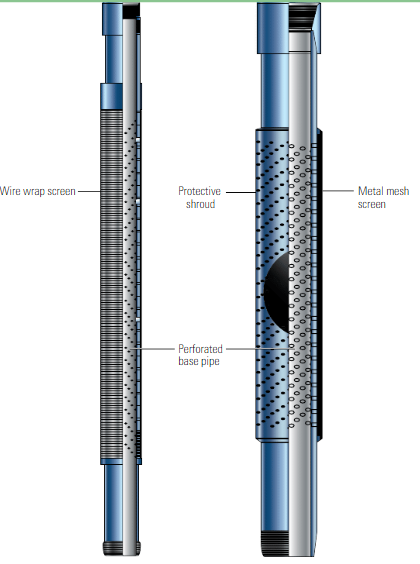

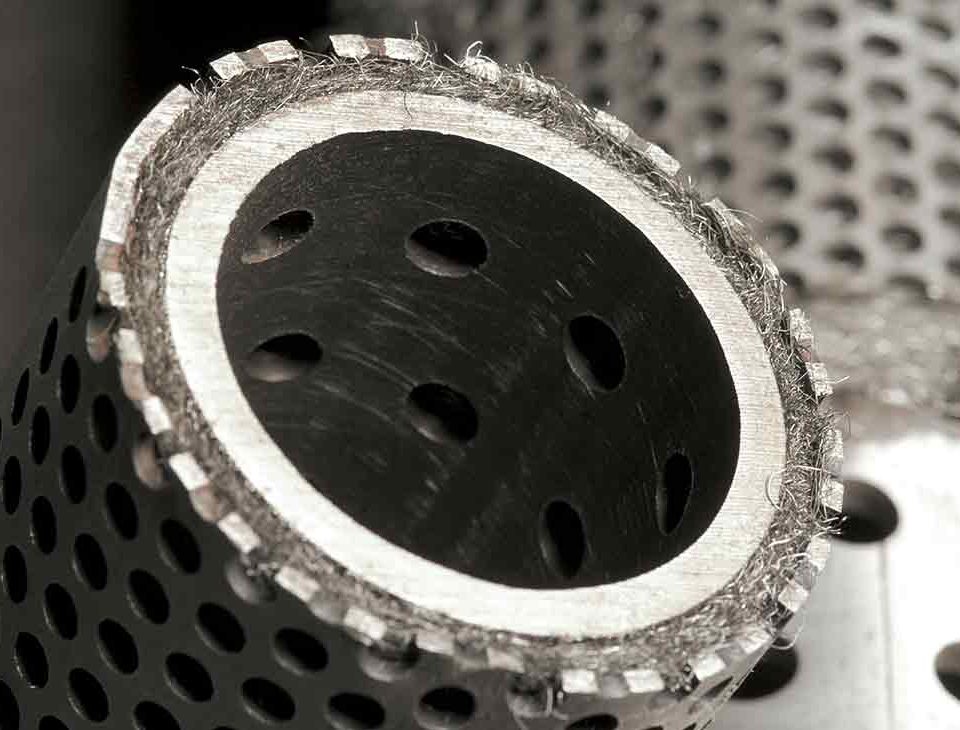

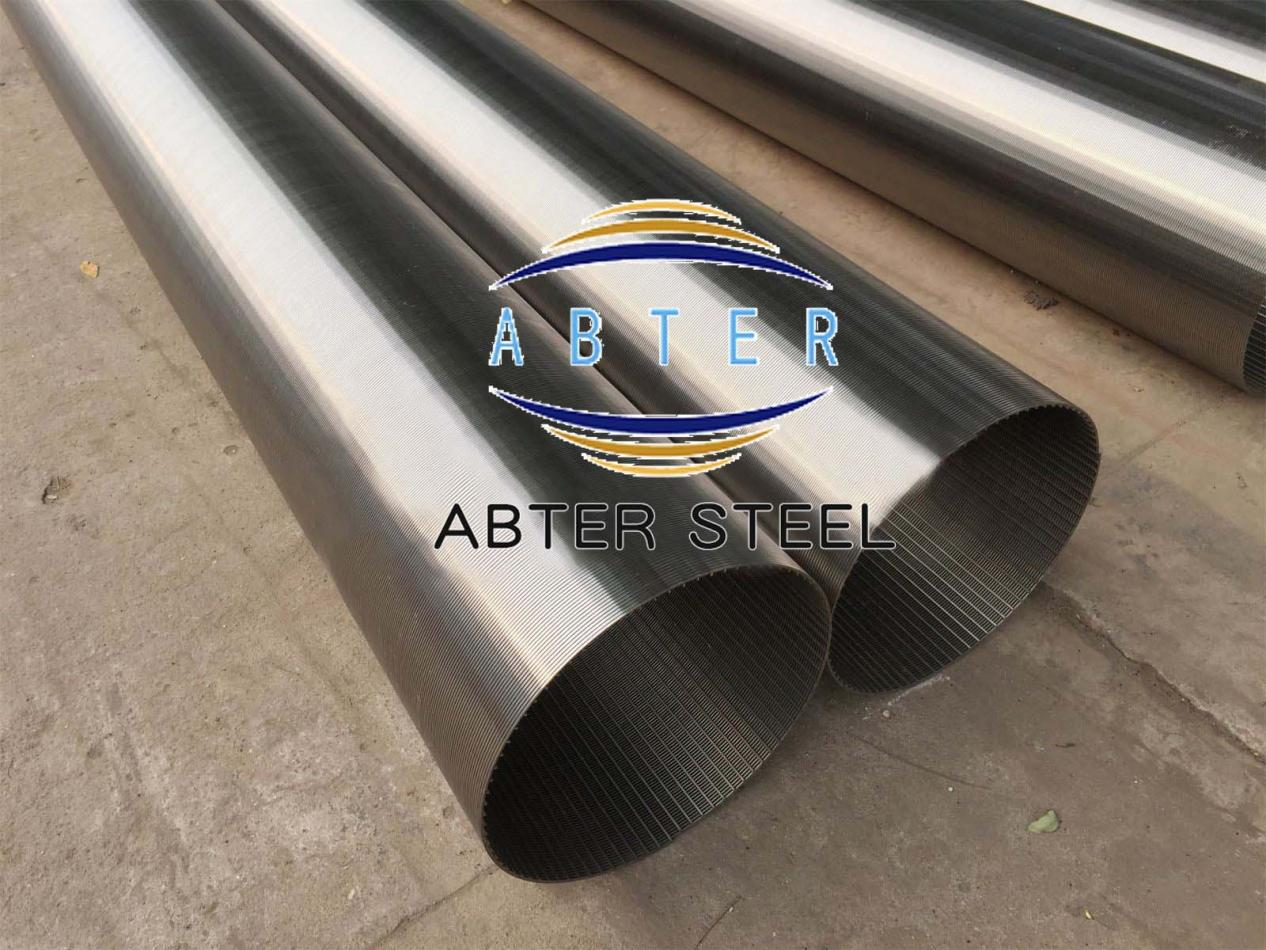

April 18, 2022- Wire-wound water filter pipe

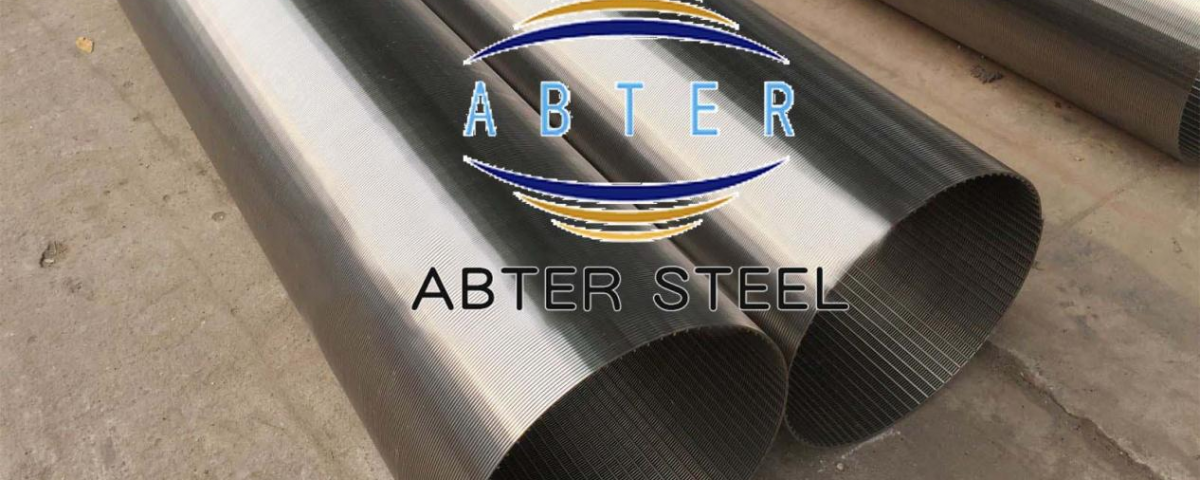

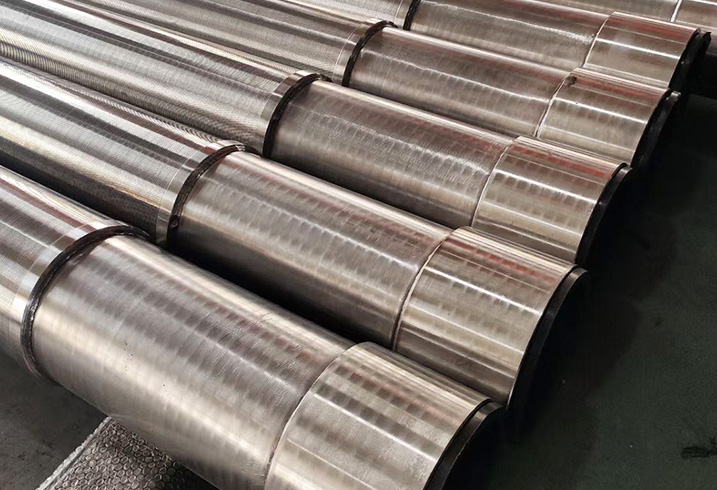

A wire-wound water filter pipe is made by welding wedge winding wire and wedge bar (or round bar) at each crossing point.

Characteristics of the product:

1.Wire-wound water filter pipe features firm structure, high porosity and accurate size of gap. It is specially fit for fine sand and silt strata of wells.

2.The opening area of the wire-wound water filter pipe is large, and its filtration area is high up to 60%.

3.Wedge-shaped design prevents screening pipe from being blocked and makes it easier for backwash.

4. The larger filtration area makes it easier for groundwater to penetrate into the well so as to obtain abundant water, reduce the depth of water level, hence reduce energy consumption.

5.The larger filtration area can relatively reduce the pressure of water infiltration, avoid sand particles entering into the well pipe under larger pressure, thus reducing the friction between sand particles and the equipment, reduce wear, and improve the service life of the equipment.

6.With the same length, diameter and gap, the flow rate of wire-wound filter pipe is 3 times that of bridge filter pipe and 9 times that of slotted filter pipe.

7.The customer can choose gap size of the screening pipe freely between 0.1mm-6mm to meet different construction conditions.

Materials of filter pipe: They are mainly stainless steel, galvanized carbon steel, plastic sprayed carbon steel or other materials required by the customer.

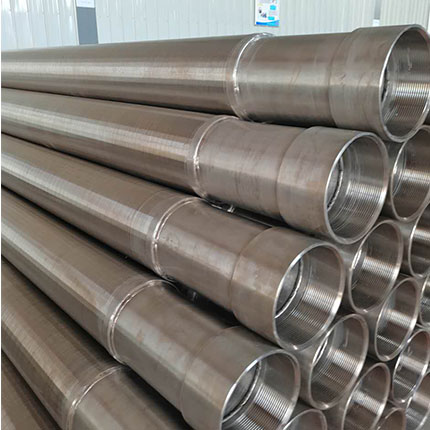

Application environment: It is fit for gravel packing and sand control in most wells such as vertical wells, inclined wells and directional wells.

Connection type: Groove connection or thread connection

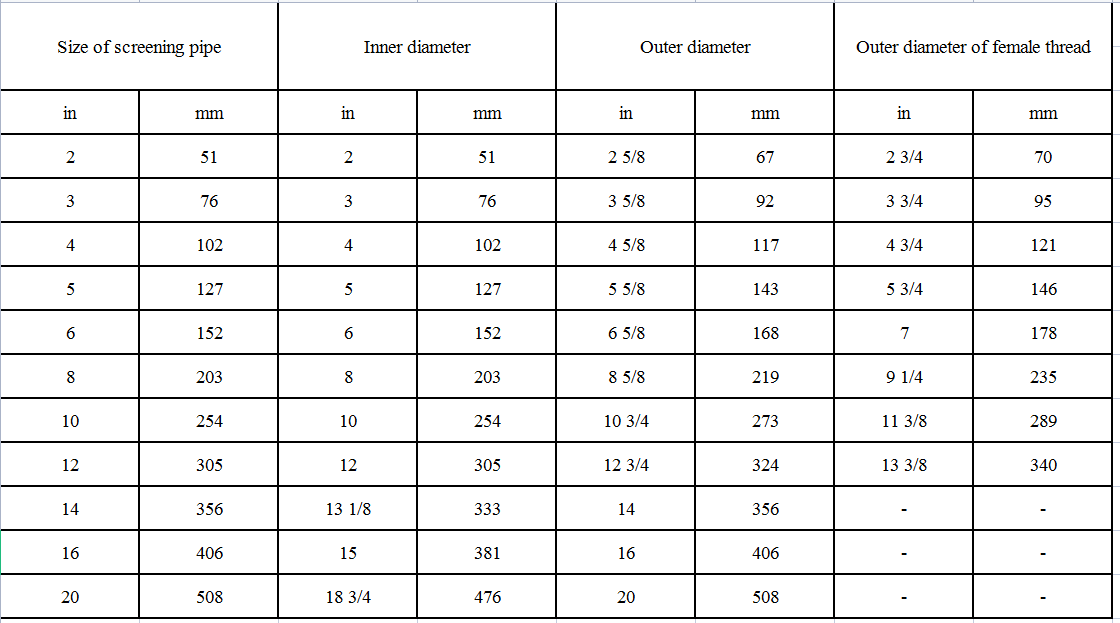

Specification