Steel pipe standards and basic knowledge

March 29, 2022

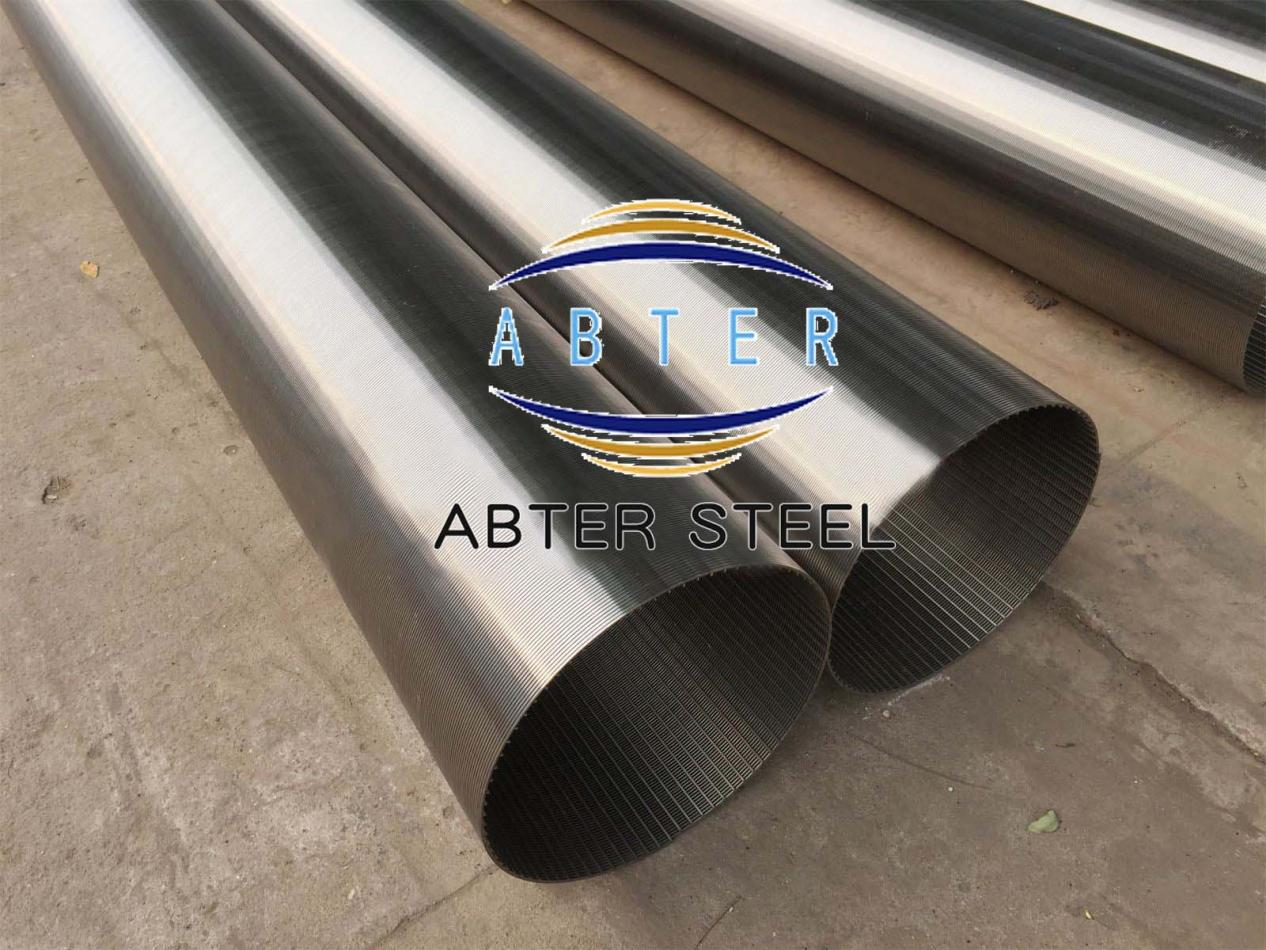

Wire-wound water filter pipe

April 12, 20221. Basic knowledge of steel pipe standards

1. Standards: Standards are repetitive things with diversity-related characteristics in economic and technological activities. On the basis of summarizing the comprehensive results of scientific technology and practical experience, they are fully negotiated by relevant parties, and are issued in specific procedures and specific forms. Uniform and guiding regulations that must be complied with within a certain range.

2. Classification of steel pipe product standards:

a) According to the promulgating agency, it is divided into: national standard (GB or GB/T), industry standard (such as YB or YB/T), enterprise standard (Henggang enterprise standard code is Q/OHAD), international standard (ISO), American standard Standards (such as: API American Petroleum Industry Association, ASTM American Society for Testing and Materials, ASME American Society of Mechanical Engineers), German Industrial Standard (DIN), Japanese Industrial Standard (JIS), British Standard (BS), European Standard (EN), CSA (Canada), DNV (Norway), Russian Standard (GOST), French Standard (NF), etc.

b) According to the standard legal attributes, it is divided into: mandatory standards and recommended standards. Mandatory standards are related to the safety of personal equipment and must be strictly implemented. When signing technical agreements for products produced according to mandatory standards, the terms of the agreement must not be lower than the mandatory standards; recommended standards, the state encourages enterprises to voluntarily adopt them. When the technical agreement of the product produced by the recommended standard is adopted, the terms of the agreement may be lower than, equal to or higher than the recommended standard. At present, there are 5 mandatory standards for seamless steel tubes, namely: GB3087-2008 “Seamless Steel Tubes for Low and Medium Pressure Boilers”, GB5310-2008 “Seamless Steel Tubes for High Pressure Boilers”, GB6479-2000 “Seamless Steel Tubes for High Pressure Fertilizer Equipment” Steel Pipe”, GB9948-2006 “Seamless Steel Pipe for Petroleum Cracking”, GB18248-2000 “Seamless Steel Pipe for Gas Cylinder”.

c) According to the level, it is divided into: international advanced level (Y), international general level (I), domestic average advanced level (H).

3. The meaning of the standard code

The standard code is referred to as the standard number. The standard number is composed of four parts: the code of the promulgating agency, the serial number of the legal attribute code, and the date of issuance.

4. The composition of steel pipe standards

The content of steel pipe standards generally consists of nine parts, including preface, scope, normative reference documents, dimensions, shape and weight, technical requirements, inspection rules for inspection methods, packaging mark quality certificates, and appendices. The core part is the size, shape, weight, and technical requirements.

Dimensions and weight usually include nominal outer diameter, nominal wall thickness, allowable deviation of outer diameter and wall thickness, theoretical weight per meter, length range, end shape, curvature, etc. Some standards also include allowable deviation of inner diameter, ovality, uneven wall thickness, allowable deviation of weight, etc.

Technical requirements generally include, grade, chemical composition, manufacturing method, delivery state, mechanical properties, process performance, metallographic structure, surface quality and non-destructive testing.

2. Common terms of steel pipe standards

1. Nominal size and actual size

Nominal size is the nominal size specified in the standard, which is the ideal size expected in the production process, but in actual production, the actual size of the steel pipe is often larger or smaller than the nominal size, and the actual size is called the actual size.

2. Deviations and Tolerances

A difference is allowed between the actual size specified in the standard and the nominal size, which is called deviation. If the difference is positive, it is called positive deviation, and if the difference is negative, it is called negative deviation. The absolute sum of positive and negative deviations specified in the standard is called tolerance, also called tolerance zone. There are absolute deviations and relative deviations.

3. Delivery length

1) Usual length: also known as indeterminate length. In the same steel pipe standard, the length of hot-rolled pipe and cold-drawn pipe is usually different, which is caused by the capacity of the unit.

2) Fixed length: cut to a fixed length according to the order requirements. Should be within the usual length range, generally allow positive deviation without negative deviation.

3) Multiple ruler length: an integer multiple of a certain length (single ruler) cut according to the order requirements. The length and multiple of the single ruler should be indicated in the contract, and the incision allowance and the deviation of the length of the multiple ruler should be considered when calculating the total length of the multiple ruler.

4) Short ruler: The length is less than the lower limit of the usual length in the standard, but not less than the minimum length allowed in the standard. Manufacturers should try to avoid the generation of short-length pipes. More and more current steel pipe standards stipulate that short-length pipes are not allowed to overlap.

5) Ruler length: also known as range length. The range of caliper lengths is narrower than usual. Some foreign standards stipulate the length of the ruler, but there is no concept of the length of the ruler in our country. If the user requires delivery in full length, the full range should be indicated in the contract. For example, the first-level length, second-level length, and third-level length in API 5CT are full-length lengths. The length of the ruler is not allowed to deviate.

4. Ovality (out-of-roundness): The ovality of the steel pipe refers to the difference between the maximum outer diameter and the minimum outer diameter on the same section, Dmax-Dmin.

5. Bending degree: the degree of unevenness of the steel pipe in the length direction. Partial curvature (also called curvature per meter) and total curvature.

6. Smelting composition and finished product composition: The smelting composition of steel refers to the chemical composition in the middle of casting after the steel is smelted. Finished composition refers to the chemical composition on finished steel, including billets. The finished product composition and smelting composition of the same furnace are allowed to have a deviation, which is stipulated in GB/T222. At present, there are GB/T222-1984 “Sampling method for chemical analysis of steel and allowable deviation of finished chemical composition” and GB/T222-1984. There are two parallel (excessive) versions of T222-2006 “Tolerable Deviation of Finished Chemical Composition of Steel”. The general situation is that the old version is stricter than the new version. The domestic product standards formulated and revised before 2006 refer to the 84th edition in the normative reference documents (GB/T222-2006 can also be used without the date), and the standards formulated and revised after 2006 are divided into three cases , one is to specify GB/T222-1984, the other is to specify GB/T222-2006, and the third is to write only GB/T222, which means to use the latest version of GB/T222. (Some standards and users specify the 84 version, in addition to which the 2006 version can be executed. Of course, our internal advocacy is to strictly control the ingredients). The sampling regulations in the 84th edition have separately formulated GB/T20066-2006 “Sampling and sample preparation methods for samples for the determination of chemical composition of steel and iron”.

7. Tensile strength, yield strength, elongation

The latest domestic standard GB/T228-2002 “Metal Materials Metal Tensile Test Method” stipulates that the tensile strength symbol is Rm; the yield strength is divided into upper yield strength ReH and lower yield strength Rel, as well as Rt0.5 and Rp0.2. The unit of tensile strength and yield strength is MPa. 1MPa=1N/mm2, 1bar=100KPa=0.1MPa. The elongation symbol is A, and the unit is %. Foreign product standards include proportional samples and non-proportional samples (calibration distance). Some foreign standards stipulate that the wall thickness is reduced, and the elongation can also be reduced, which should be fully paid attention to when judging the quality.

8. Impact energy: the work absorbed by a sample of specified shape and size when broken under one impact test force. The commonly used impact tests are U-type and V-type specimens. The so-called U-shape and V-shape refer to the notch shape. V-type samples include full-size samples (height x width) 10mm x 10mm, 3/4-size samples 10mm x 7.5mm, half-size samples 10mm x 5mm, or other smaller size samples, and you should pay attention to their conversion relation. The impact also includes longitudinal impact and lateral impact, try to use large size specimens. The API 5CT standard specifies that impact specimens require the use of transverse specimens first and then larger specimens. The re-inspection of unqualified impact energy of domestic products shall be carried out according to GB/T2102-1988 or GB/T2102-2006.

9. Hardness: the ability to resist the indentation of hard objects on the surface. Divided into Brinell hardness (HB), Rockwell hardness (HRB, HRC), etc.

10. Process performance: It is used to test the applicability of the quality of the steel pipe in the subsequent processing and manufacturing process. Commonly used process properties include water pressure, flattening, bending, flaring, and crimping tests.

11. Steel grade: The performance index of steel is used as the representation method of its code. Usually expressed as the lower limit of yield strength. Such as Q345 (A, B, C, D, E), L245, N80, S135 (135,000PSi)

12. Delivery status: the final plastic deformation processing or final heat treatment status of the delivered steel pipe. The commonly used delivery states of steel pipes are: hot rolling, annealing, normalizing, normalizing + tempering, quenching + tempering (also known as quenching and tempering) Annealing: the workpiece is slowly heated to a certain temperature, cooled for a period of time, and then A heat treatment process in which the furnace is slowly cooled, also known as furnace cooling, and normalizing is to take out the heated workpiece and cool it in the air, which is called air cooling. Quenching is to heat the workpiece and put it in a quenching agent for cooling, and tempering is to heat the workpiece at a lower temperature and then cool it after quenching.

13. Batch: According to the prescribed principles, a certain number of steel pipes are formed into an inspection unit and become an inspection batch. The batch referred to in the standard is an inspection batch, not a delivery batch or a production batch. Note: Some foreign standards and domestic standards formulated after 2008 stipulate that if the steel pipe is not heat treated after being cut into a single piece, all pipe sections cut from a steel pipe rolled from a billet should be regarded as one.