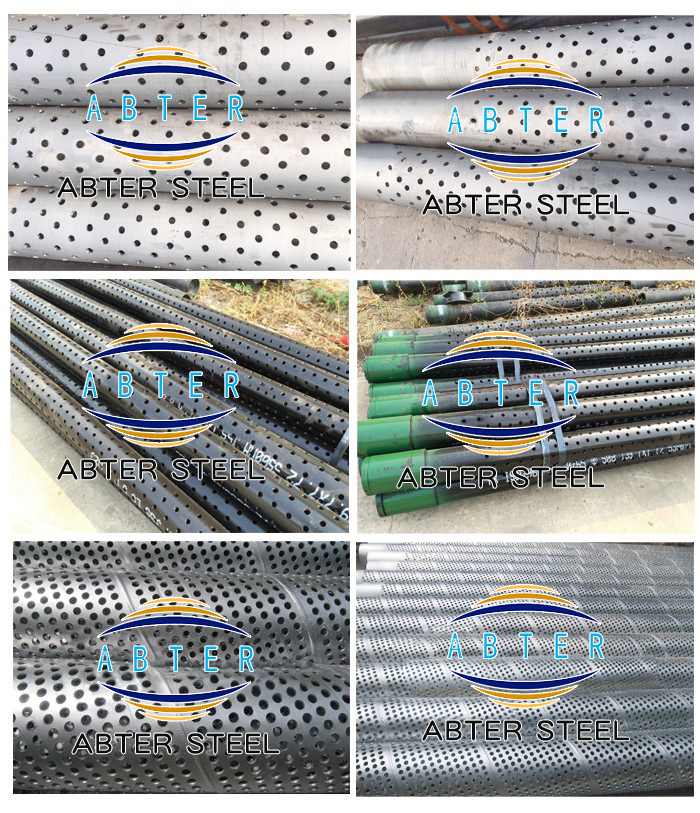

Hole-drilled pipe&Water filter pipe for geothermal well&Water filter pipe of air-conditioning well

April 18, 2022

Steel Pipe Piles Overview and Construction Method

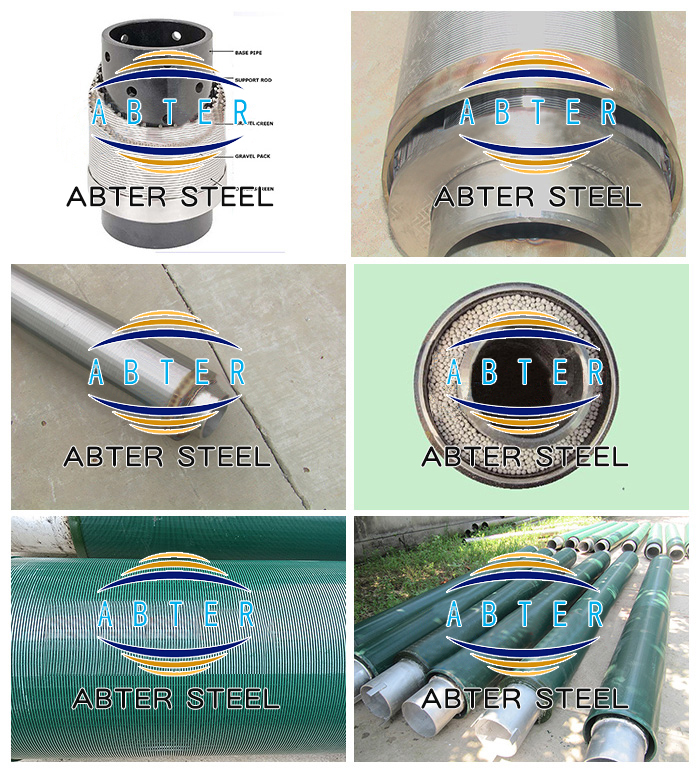

May 9, 2022- Double-layer lined screening pipe

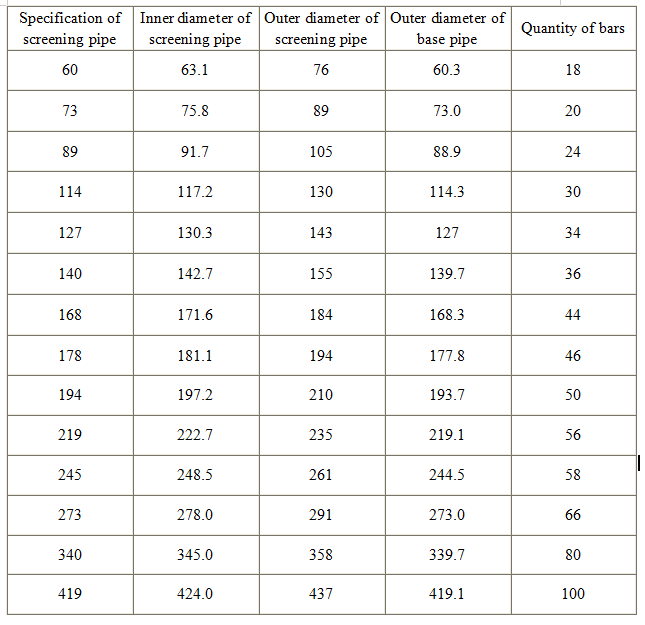

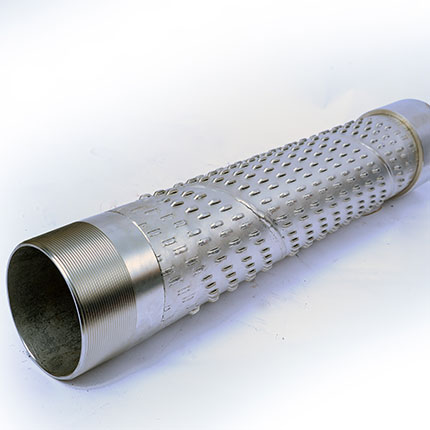

The double-layer lined screening pipe is composed of a base pipe of API standard, a double-layer high precision wedge wire filter pipe and lined filter material in between.

Characteristics of the product:

1.High-precision screening gap can effectively control sand and act as a protective medium.

2.The use of double-layer lined screening pipe can reduce diameter of drilling hole, save drilling time, and reduce drilling cost.

3. The use of double-layer lined screening pipe can reduce the workload of operators, and improve the success rate of drilling.

4.Filter material can be selected to effectively inhibit microbial ceramic particles, or standard sand and resin particles.

5.By adjusting the screening gap, leakage of filter material can be effectively prevented, and the service life prolonged.

6.In the long run, double-layer lined screening pipe brings lower operating costs for customers.

7.Base pipe meeting API standard can be built inside according to the requirements for use to increase the overall bearing capacity of the screening pipe, so as to be used in deeper strata.

Application environment: It is fit for vertical wells, inclined wells, directional wells and most wells as well as deep wells and strata in special environments.

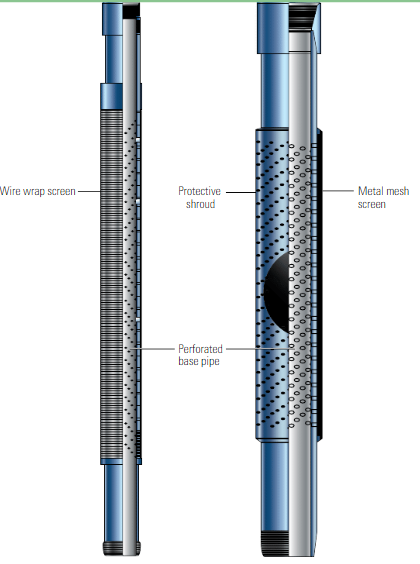

2. Sand-control screening pipe for oil well

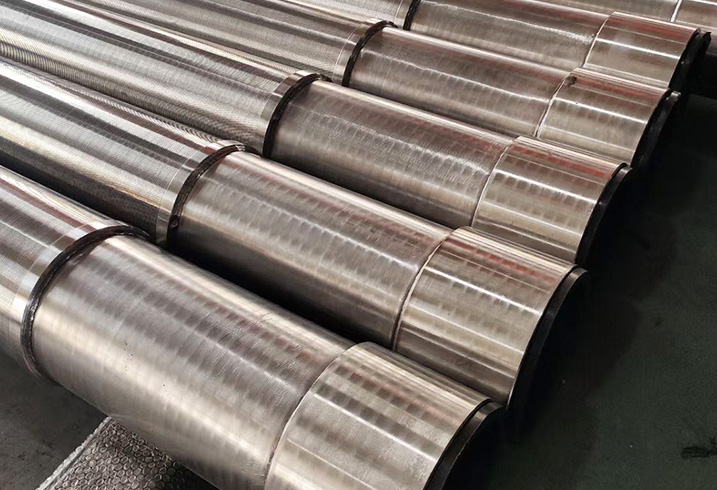

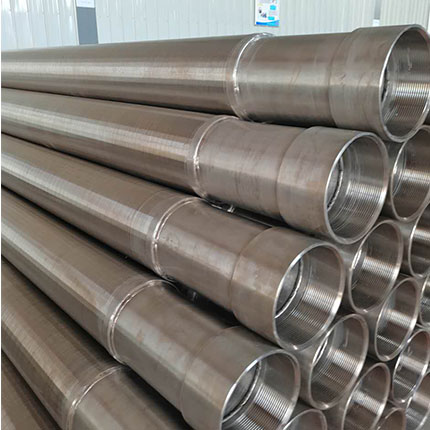

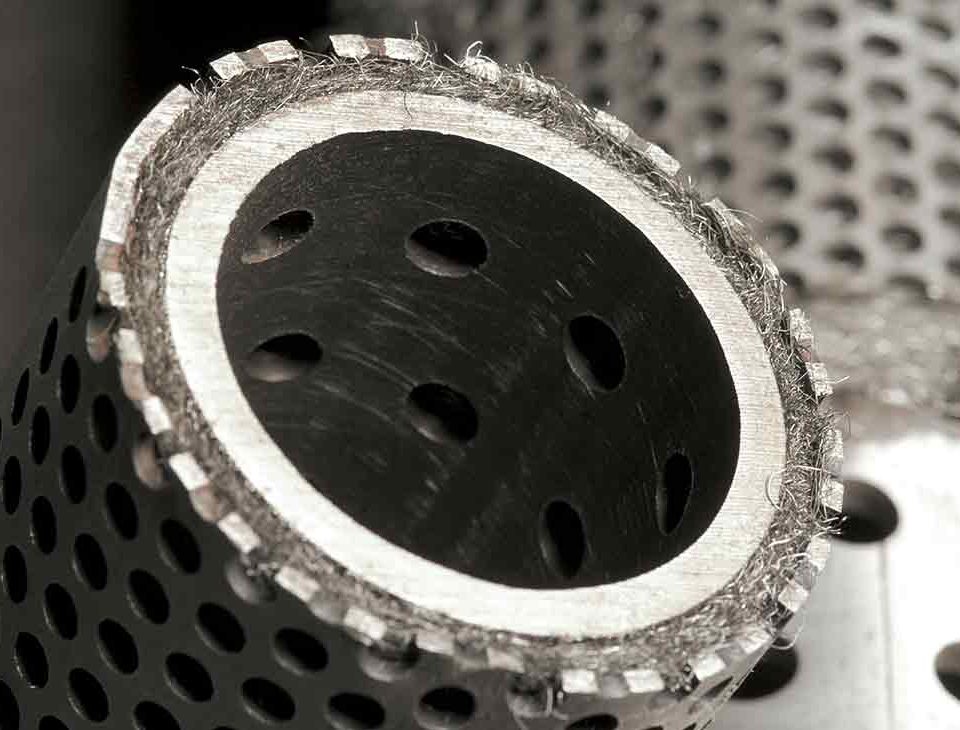

A sand-control screening pipe for oil well is composed of a base pipe of API standard and a high precision water filter pipe.

Characteristics of the product:

1.It has strong pressure bearing capacity. With the support of the inner-layer base pipe, even if external filter pipe is deformed partially, the gap will not increase, and sand control performance will be more reliable. It is fit for a harsh service environment.

2.The gap of the outer-layer screening pipe is uniform, the error is as small as 0.05mm, which can control sand effectively.

3.Gap density of the screening pipe is better than other screening pipes, which reduces the flow resistance and greatly improves the oil and gas yield.

4.Pipe diameter is smaller, which reduces the difficulty of drilling construction.

5.Continuous V-shaped structure reduces the water penetration speed and alleviates the pressure on the pipe body and the equipment.

6.Materials of the base pipe is J55, K55, N80, etc of API standard, those of the outer-layer screening pipe is 304 stainless steel, and other materials can also be used in accordance with the customer’s requirements as well.

Application environment: 1000-meters deep wells, oil wells, geothermal wells and strata with poor construction conditions.