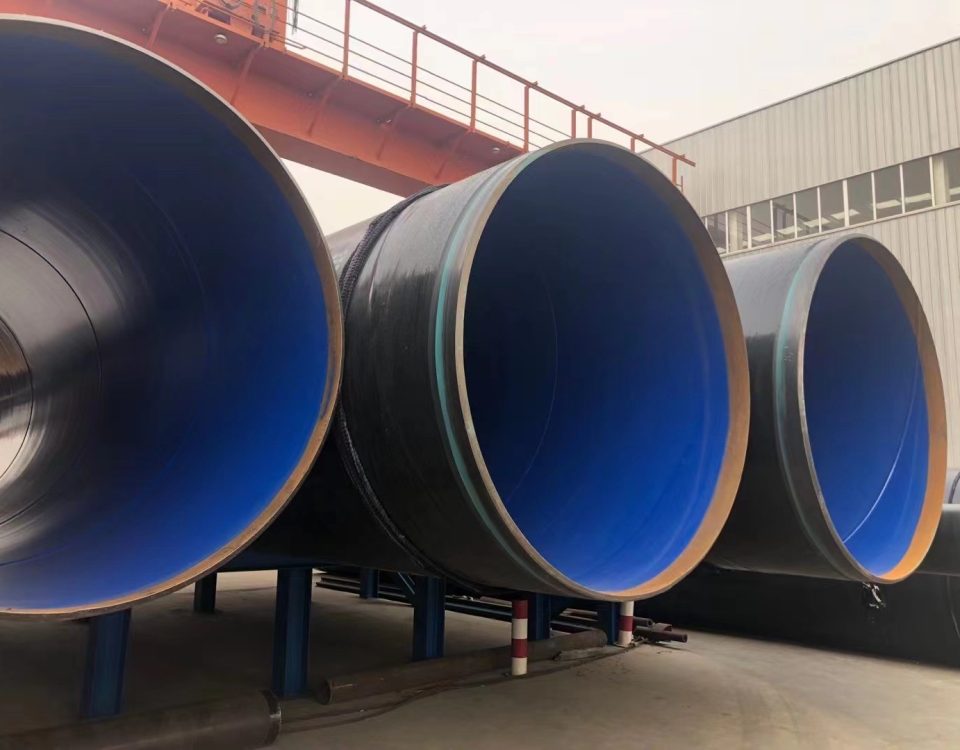

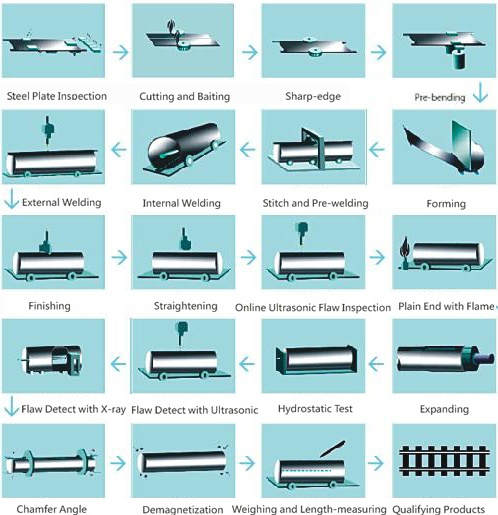

process of Coated Steel Pipe

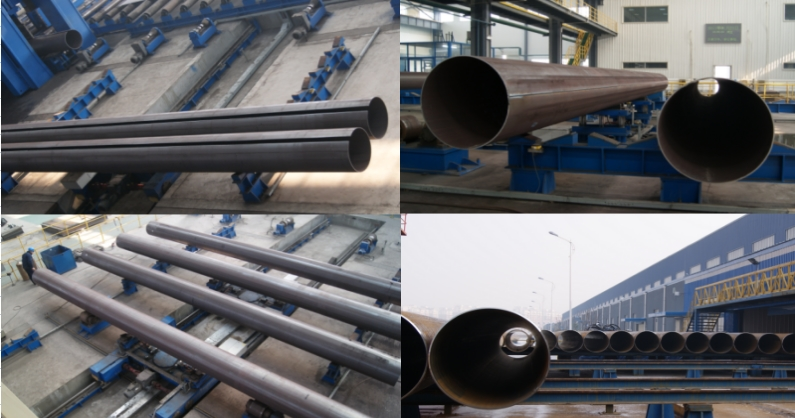

February 27, 2017process of SSAW Steel Pipe

February 27, 2017

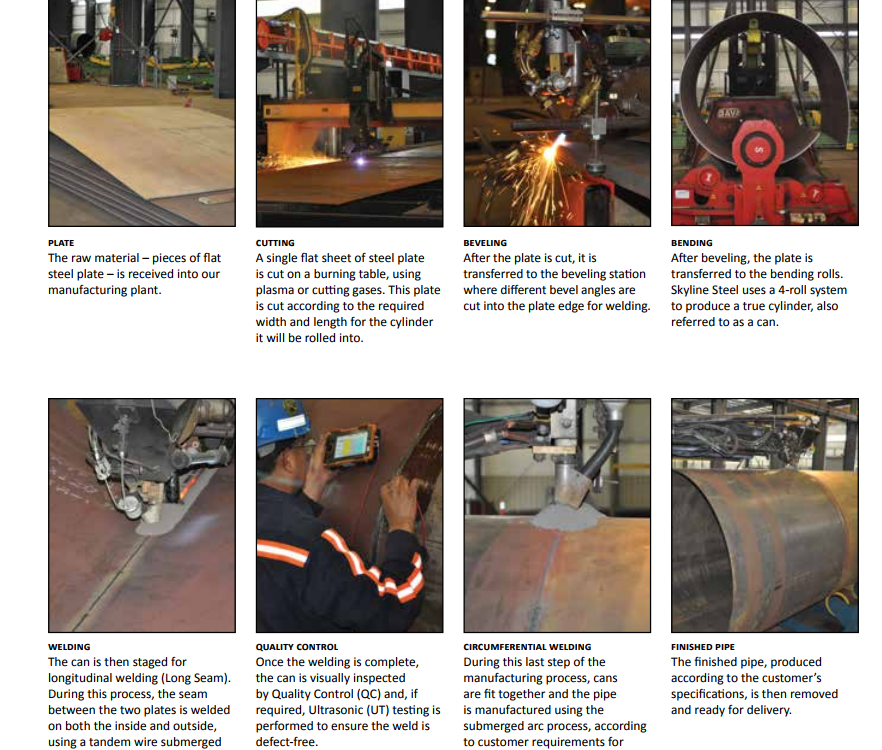

Internal weld

The device is controlled by microcomputer, which can automatically identify the flaw in the steel plate, give alarm, locate and mark according to the set standard of flaw detect and inspection; besides, it can comprehensively evaluate the inspection result, determine the flaw grade and print the inspection report forms as well. It has the characteristics such as easy operation and high inspection efficiency.

External weld

The device is controlled by microcomputer, which can automatically identify the flaw in the steel plate, give alarm, locate and mark according to the set standard of flaw detect and inspection; besides, it can comprehensively evaluate the inspection result, determine the flaw grade and print the inspection report forms as well. It has the characteristics such as easy operation and high inspection efficiency.

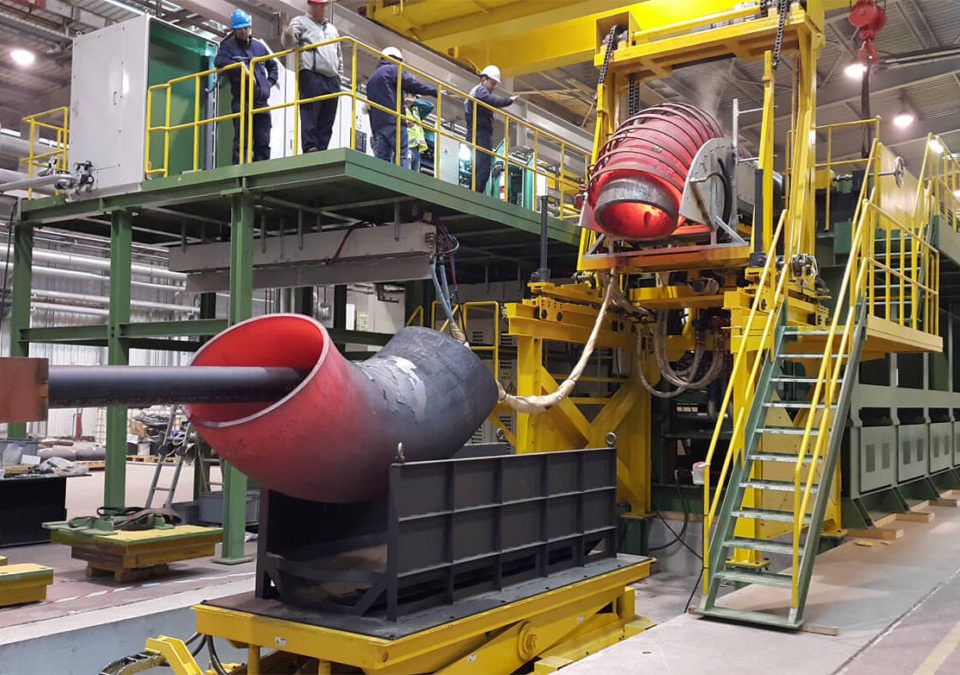

Finishing machine

Circular tube finishing machine——Adopt three control methods such as automatic pressure control, automatic position control and manual control. Be operated neatly and conveniently. The roundness of the pipes can be ensured for that the pipes are formed with relevant arc mould as per various pecifications.

Straightening machine

The machine possesses the accurate micro-inching function, can adjust the micro-inching devices and V-shaped former block as per different specification. Besides, through removing the movable framework to the relevant position to press the pipe asper the curve situation can ensure the straightness.

Ultrasonic online flaw inspection

Controlled automatically by the micro-computer, the inspection blind area is less than 200mm; it can automatically identify the flaw in the weld and the heat effect area, give alarm and locate and mark the flaw, besides, determine the flaw grade and print the inspection report forms as well.

Hydrostatic test

The device is controlled by microcomputer, which can automatically identify the flaw in the steel plate, give alarm, locate and mark according to the set standard of flaw detect and inspection; besides, it can comprehensively evaluate the inspection result, determine the flaw grade and print the inspection report forms as well. It has the characteristics such as easy operation and high inspection efficiency.

X-Ray flaw detect

Radial Generator is imported from America, is used for 100% inspection of the internal & external weld with industrial TV, the image data is stored in real time, the part within 200mm of the pipe ends is taken picture with X-ray. The inspection result is traceable and the quality can be ensured.

Pipe end chamfering machine

The device is controlled by microcomputer, which can automatically identify the flaw in the steel plate, give alarm, locate and mark according to the set standard of flaw detect and inspection; besides, it can comprehensively evaluate the inspection result, determine the flaw grade and print the inspection report forms as well. It has the characteristics such as easy operation and high inspection efficiency.

Expanding mill

The device is controlled by microcomputer, which can automatically identify the flaw in the steel plate, give alarm, locate and mark according to the set standard of flaw detect and inspection; besides, it can comprehensively evaluate the inspection result, determine the flaw grade and print the inspection report forms as well. It has the characteristics such as easy operation and high inspection efficiency.