API 5CT PSL casing tubing product specification range

April 20, 2018

A335 alloy steel pipe Grade P5 P11 for Brazilian Petrobras company, GRADE P5 P11

April 22, 2018According to the different pipe-making process, the steel pipe can be divided into seamless steel pipe (SML), which is mainly used as the internal oil collection pipe and small-diameter high-pressure natural gas transmission pipe. The number of long-distance oil and gas transmission pipelines is very small, and most of the long-distance pipelines are It adopts three types of straight seam high-frequency welded pipe (ERW), spiral submerged arc welded pipe (SSAW), and LSAW (LSAW). The following table shows the process characteristics and quality performance comparisons of several types of steel pipes:

ERW PIPE

API ERW Carbon Steel Pipes Standard related to Grade:

Outer Diameter : 88.9mm—660.4mm

Thickness : 3mm–22mm

Length : 3m–20m

Standard : BS EN 10219, EN 10217, EN10224, ASTM A53, A106, API, JIS G3444, and GB/T3091, GB/T9711

Grade : S235-S355, L235-L355, P195-P460, GR. A, GR. B, X42 ~ X70, J55, STK400, STK500,SS400, Q195, Q215, Q235, and Q345,

| No. | Name | Standard | Grades | Application |

| 1 | Casing Pipes | API 5CT | H40,K55, N80-1,J55 |

For oil-gas well casing |

| 2 | Line Pipes | API 5L | A, B–X70 L210–L485 |

For the pipeline transportation of oil and natural gas |

| 3 |

Welded Steel Tubes For Pressure Purposes |

EN10217-1 | P195TR1 P195TR2 P235TR1 P235TR2 P265TR1 P265TR2 |

Welded Steel Tubes For Pressure Purposes |

Straight seam high-frequency welded pipe (ERW) is divided into two types of induction welding and contact welding according to different welding methods. Hot-rolled wide-gauge steel coil is used as raw material, after pre-bending, continuous forming, welding, heat treatment, sizing, straightening, Cutting and other processes, compared with spiral welded pipe with a short weld, high dimensional accuracy, uniform wall thickness, surface quality, high pressure, but the disadvantage is that only small and medium diameter thin-walled pipe, the weld is easy to produce gray spots , unfused, pitted corrosion defects. At present, the most widely used areas are urban gas and crude oil product transportation.

When the spiral submerged arc welded pipe (SSAW) is a coiled steel pipe, its advancing direction has a forming angle (adjustable) with the centerline of the forming pipe, and the edge is welded while forming. The welding seam is a spiral line. The advantage is that the same specification steel strip can be produced. A variety of diameters of steel pipe, raw material to adapt to a larger range, the weld can avoid the main stress, the force is better, the disadvantage is that the geometric size is poor, the weld length is longer than the straight seam pipe, easy to produce cracks, pores, Slag inclusion, welding deviation and other welding defects, the tensile stress of the welding stress. The design specifications for general oil and gas transmission pipelines stipulate that spiral submerged arc welded pipe can only be used in Class 3 and Class 4 areas. After the improvement of this process in foreign countries, the raw material is changed to a steel plate, so that the forming and welding are separated. After pre-welding and fine boring, after the cold expansion of welding, the welding quality is close to the UOE pipe. At present, there is no such process in China. It is a spiral pipe in China. The direction of plant improvement. The spiral pipe used in the “West-to-East Gas Transmission” is still produced according to the traditional process, but the pipe end has been expanded. The United States, Japan, and Germany generally deny SSAW and believe that SSAW should not be used in trunk lines; SSAW is used in Canada and Italy, and SSAW is used in small quantities in Russia. Both of them have very strict supplementary conditions. Due to historical reasons, the majority of domestic trunk lines still use SSAW. .

SSAW STEEL PIPE (SPIRAL STEEL PIPE)

| Commodity | Spiral Steel Pipes/API 5L |

| Outside Diameter | 219–3048mm(Round). |

| Wall thickness | 5mm-25.4mm. |

| Standard | ASTM A53, ASTM A252, API 5L, SY/T 5037,GB/T 9711.1, GB/T 9711.2,EN 10219, EN10217,etc. |

| Steel Grade | API 5L: GR A, GR B, X42, X46, X52, X56, X60, X65, X70 BS 4360: Grade 37, Grade 50 EN: S275JR, S275J0H, S275J2H, S355JRH, S355J0H, S355J2H |

LSAW (Large-Surface Submerged-Arc Welded Pipe) is produced by using a single medium-thickness plate as a raw material, and pressing (rolling) the steel plate into a tube blank in a mold or a molding machine, adopting a double-sided submerged arc welding method and expanding the diameter. Its product specification range is wide, the toughness, plasticity, uniformity and compactness of the weld seam are good. It has the advantages of large diameter, thick wall thickness, high pressure resistance, low temperature resistance and strong corrosion resistance. When building high-strength, high-toughness, high-quality long-distance oil and gas pipelines, most of the required steel pipes are large-caliber thick-walled LSAW pipes. According to API standards, LSAW pipe is the only designated type of pipe to be used in large-scale oil and gas transmission pipelines when passing through Class 1 or Class 2 areas such as the alpine zone, submarine, and densely populated urban areas. According to different molding methods, they can be divided into:

UOE welded pipe: single steel plate after the edge of pre-bending, after U molding, O molding, internal welding, welding, mechanical cold expansion and other processes;

JCOE welded pipe: press “J-C-O-E” pre-welding, forming, welding, cold expansion and other processes;

HME welded pipe: It is formed by the “C-C-O” method of mandrel rolling method, and the process of cold expansion after welding.

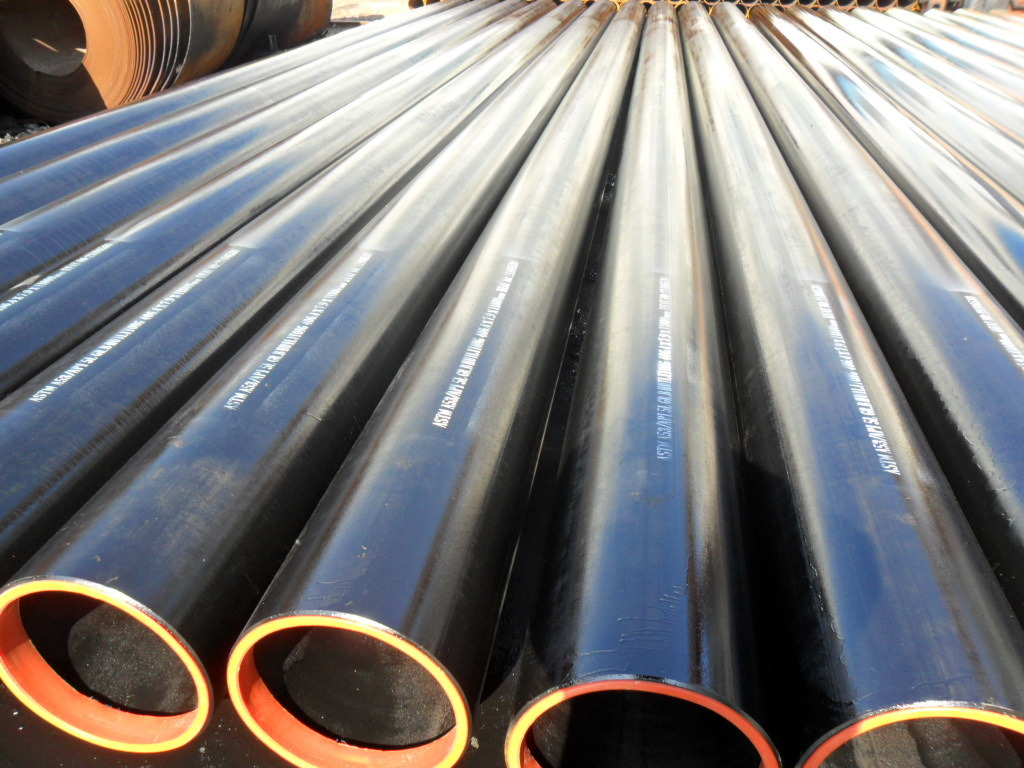

LSAW carbon steel pipe

Size: O. D. 219mm-660mm, W. T. 5-20mm

Length: 5M~22M, length can be manufactured by customer requirement

Standard GB/T 3091, GB/T 13793, ASTM A252, ASTM A53, ASTM A500, EN 10210, EN 10219, API 5L, DIN 1626/1615, DIN 17120, etc.

Grade SS400, Q235, Q345, Q460, A572 Gr.50, A572 Gr.60, S235, S275, S355, Grade A/B, X42, X52, X60, X70, etc.

| Outer diameter | ERW / HFW | LSAW / DSAW | SSAW / HSAW | RHS | SHS |

| 1/8 – 20 inch (10.3 – 508 mm) |

12 – 56 inch (323.8 – 1,420 mm) |

8 – 126 inch (219.1 – 3,200 mm) |

40 x 20 mm – 1,000 x 800 mm |

15 x 15 mm – 1,000 × 1,000 mm |

|

| Wall thickness | 0.4 – 16 mm | 6.0 – 40 mm | 6.0 – 26 mm | 1.0 – 30 mm | 0.6 – 30 mm |

| Length | 5.8 ~ 12.0 m or upon customers’ requirements | ||||