The manufacturing process and popularization and application of thick-walled pipe

September 22, 2021After-sales service of steel pipe products

October 8, 2021The common quality problems of steel pipes are divided into the following categories:

1. The internal and external quality of steel pipes;

2. Quality problems of geometric dimensions;

3. Unqualified quality problems of physical and chemical properties;

4. Quality problems of tubing and casing threads;

5. Quality problems of users in the process of processing and use;

6. The quality of packaging labeling.

1. The internal and external quality of the steel pipe

The appearance quality problems of steel pipes include: external folds, cracks, splits, holes, punctures, external threads, corrections, bumps, pitted surfaces, rolling, folding.

Outward folding quality defect: It is caused by the cracks in the billet itself, which are produced after rolling the tube, and the outward folding becomes an oblique spiral shape, as shown in the figure below:

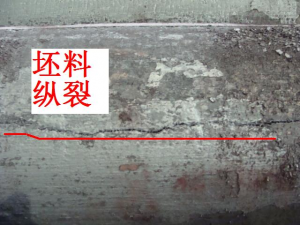

Quality defects of cracks and cracks: due to the presence of small inclusions or small pores in the grain boundaries of the blank, the obvious ones are exposed in the rolled tube, and the invisible cracks that are difficult to find are formed if they are not obvious, as shown in the figure.

Obvious gap:

Inconspicuous cracks:

Pore quality defects: one is because there are large inclusions in the billet that cause holes after the tube is rolled, and the other is that the quality of the billet is not problematic. It is caused by improper adjustment of the parameters of the continuous rolling mill. It is common on thin-walled pipes with large D/S, as shown in the figure.

Quality defects of external thread and correction: generated on the straightening machine, caused by improper adjustment of the straightening machine, the defects are regularly spiral, as shown in the figure below:

Pit surface quality defects: produced in annealing furnace or tempering furnace, low-grade steel pipes are delivered in cold drawn annealed and hot-rolled state, and pocked surface produced in annealing furnace and reheating furnace is caused by excessive heating time or high temperature , The high-steel steel pipe needs to be quenched and tempered and the pitted surface is produced on the tempering furnace, as shown in the figure.

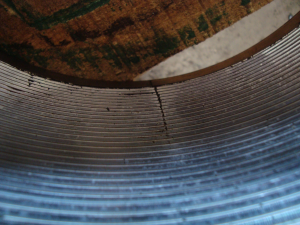

Rolling and folding quality defects: generated on the continuous rolling mill, caused by the excessive outside diameter of the incoming capillary tube or the dislocation of the rack. The defect is in a straight line, and sometimes the rolling is very hidden and cannot be found. This defect is very dangerous because it has damaged the body of the steel pipe and is difficult to find, as shown in the figure.

Folding defect:

The quality problems of the inner surface of the steel pipe include: internal folding, internal thread, internal warping skin, internal pit, internal scribe, etc.

Quality defect of inner warping skin: it is caused by large inclusions in the billet which appeared after rolling the tube, as shown in the figure.

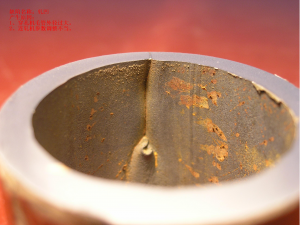

Quality defects of inward fold: First, the blank has inclusions; second, it is caused by improper heating; third, it is caused by sticking steel on the perforated top or the amount of piercing is too small, and the spiral shape of the inward fold is the sticking steel tape on the perforated top , See picture.

Second, the quality of geometric dimensions

Outer diameter tolerance, wall thickness tolerance, length tolerance, ellipticity tolerance, bending (straightness tolerance), inner hexagon, steel tube unilateral.

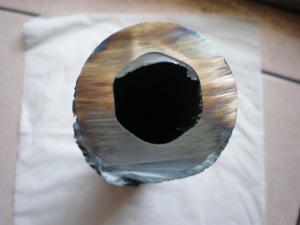

Inner hexagonal quality defects: often occur on thick-walled pipes with small D/S, as shown in the figure above, it is difficult to overcome and can only be mitigated by the process itself.

The bending of the steel pipe is shown in the figure below:

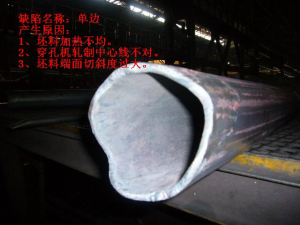

Unilateral quality defects of steel pipe: unilateral steel pipe is also called uneven wall thickness, which is caused by the uneven heating of the blank and the wrong center line of the piercing machine, see the figure below.

third, Unqualified physical and chemical properties

According to the contract or standard steel pipe, the chemical composition (mixed steel or alternative steel), tensile strength, yield strength, impact performance, hardness, elongation, flattening performance, flaring, bending performance, etc. are unqualified, and the above problems occur, the main reason is One is the production of mixed materials; the other is the contract to replace steel; the third is that the production process is not strictly controlled.

Fourth, the quality of tubing and casing threads

Velcro, trip, tight pitch of thread, thread grease, eccentricity of threaded thread, unfastened coupling, see the figure below.

Coupling is not tightened

Velcro

Five, the quality of the user in the process of processing and use

There are middle cracks, pores, processing fractures, inclusions.

Bending fracture

Cracks in the wire

Inclusions during processing

Six, packaging, labeling, anti-corrosion quality issues

Rust, unclear markings, loose bundles, incorrect markings.

The outlet pipe has been painted and rusted

Bulk steel pipe

The plug does not meet the requirements

Unsatisfactory painting

The spray mark does not meet the requirements

The spray mark does not meet the requirements