Monel Alloy 400 UNS N04400 steel Pipe

January 22, 2024

Hastelloy C276 UNS N10276 Inconel Alloy Steel Pipe

January 24, 2024Inconel 601 UNS N06601 is a nickel-chromium alloy that offers excellent high-temperature strength and resistance to oxidation. It is commonly used in applications that require elevated temperature resistance, such as heat treatment equipment, furnace components, and gas turbines. Inconel 601 UNS N06601 seamless steel pipe is a seamless pipe made from this alloy, providing seamless and reliable performance in high-temperature environments.

Chemical Composition:

The chemical composition of Inconel 601 UNS N06601 includes the following elements:

- Nickel (Ni): 58.0 – 63.0%

- Chromium (Cr): 21.0 – 25.0%

- Iron (Fe): Balance

- Aluminum (Al): 1.0 – 1.7%

- Carbon (C): 0.10% maximum

- Manganese (Mn): 1.0% maximum

- Sulfur (S): 0.015% maximum

- Silicon (Si): 0.5% maximum

- Copper (Cu): 1.0% maximum

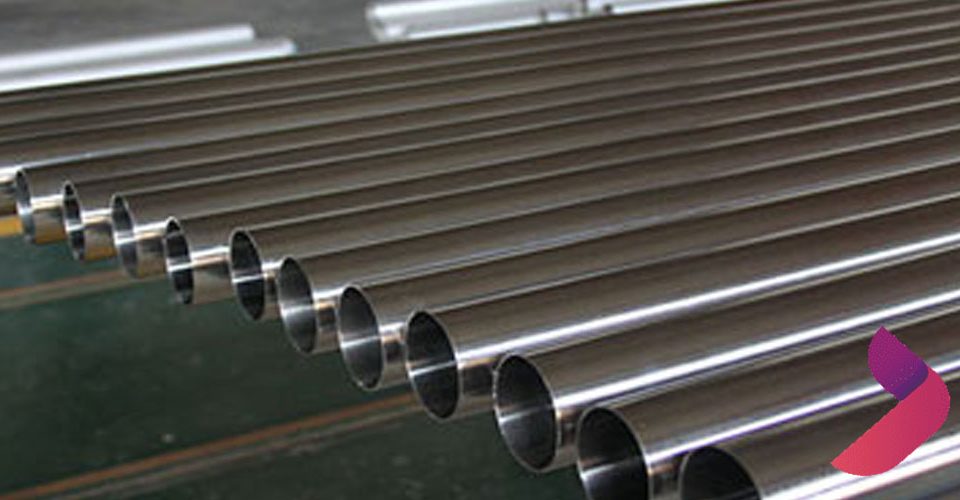

Seamless Steel Pipe:

The Inconel 601 UNS N06601 seamless steel pipe is manufactured using a seamless process, which involves the absence of any welded joints or seams. This seamless construction provides several advantages, including enhanced strength, improved corrosion resistance, and the ability to withstand high-temperature environments.

Inconel 601 Physical Constants:

In addition to its chemical composition, Inconel 601 has specific physical constants that contribute to its overall characteristics. These include:

- Density: The density of Inconel 601 is approximately 8.1 Mg/m³. This value indicates the mass per unit volume of the material and is useful for various engineering calculations.

- Melting Range: The melting range of Inconel 601 is between 1320-1370 ℃. This temperature range represents the interval at which the alloy transitions from a solid to a liquid state.

UNS N06601 Mechanical Properties:

The mechanical properties of Inconel 601, specified by the UNS N06601 standard, are as follows:

- Tensile Strength (min): 552 MPa

- Yield Strength (min): 207 MPa

- Elongation in 2 in. or 50mm (min): 30%

- Hardness (max HRC): Not specified

Properties:

The Inconel 601 UNS N06601 seamless steel pipe exhibits the following properties:

- High Temperature Strength: Inconel 601 UNS N06601 has excellent strength at high temperatures, allowing it to withstand extreme heat without significant deformation or failure.

- Oxidation Resistance: The alloy offers exceptional resistance to oxidation, even in environments with high levels of oxygen and sulfur. This property makes it suitable for applications involving combustion processes and exposure to corrosive gases.

- Corrosion Resistance: Inconel 601 UNS N06601 demonstrates good resistance to a wide range of corrosive media, including acids, alkalis, and aqueous solutions. It is particularly resistant to stress corrosion cracking and chloride-induced corrosion.

- Thermal Stability: The alloy maintains its mechanical properties even after prolonged exposure to high temperatures, making it suitable for long-term use in heat treatment and thermal processing applications.

Applications:

The Inconel 601 UNS N06601 seamless steel pipe finds applications in various industries, including:

- Heat Treatment Equipment: Inconel 601 UNS N06601 seamless steel pipes are used in the construction of heat treatment furnaces, where they provide excellent resistance to high temperatures and oxidation.

- Petrochemical Industry: The alloy is utilized in the petrochemical industry for applications such as reformer tubes, radiant tubes, and catalyst support grids, where it can withstand the harsh conditions of high-temperature and corrosive environments.

- Power Generation: Inconel 601 UNS N06601 seamless steel pipes are used in gas turbine components, such as combustor cans and transition ducts, due to their ability to withstand high temperatures and resist oxidation.

- Aerospace Industry: The alloy is employed in aircraft components, including exhaust systems and engine parts, where it offers high-temperature strength and resistance to thermal fatigue.

- Chemical Processing: Inconel 601 UNS N06601 seamless steel pipes are used in chemical processing plants for applications involving corrosive chemicals and high-temperature environments.

Conclusion:

Inconel 601 UNS N06601 seamless steel pipe is a reliable and high-performance material that offers excellent high-temperature strength, oxidation resistance, and corrosion resistance. Its seamless construction ensures enhanced durability and reliability in demanding applications. Whether in heat treatment equipment, petrochemical plants, power generation, aerospace, or chemical processing, Inconel 601 UNS N06601 seamless steel pipe is a trusted choice for withstanding extreme conditions and maintaining performance over time.

When it comes to test certificates, we offer the following:

- Manufacturer TC (Test Certificate) in accordance with EN 10204/3.1B: This certificate confirms that the Inconel 601 tubes have been manufactured in compliance with the specified standards and that the material meets the required specifications.

- Raw Materials Certificate: This certificate provides information about the raw materials used in the production of the Inconel 601 tubes. It assures our customers that the materials used are of high quality and suitable for the intended application.

- 100% Radiography Test Report: We conduct radiography testing on our Inconel 601 tubes to ensure the absence of any internal defects or flaws. The radiography test report provides evidence of the structural integrity of the tubes.

- Third Party Inspection Report: We also facilitate third-party inspections to provide an unbiased assessment of the quality and conformity of our Inconel 601 tubes. The third-party inspection report adds an additional layer of assurance for our customers.

In addition to test certificates, we offer various value-added services to enhance the overall quality and reliability of our Inconel 601 tubes. These services include:

- Mechanical Testing: We perform mechanical tests, such as tensile strength and hardness tests, to assess the mechanical properties of the Inconel 601 tubes. These tests ensure that the tubes meet the required strength and hardness specifications.

- Chemical Analysis – Spectro Analysis: Our spectro analysis process examines the chemical composition of the Inconel 601 tubes, ensuring that they meet the specified elemental composition requirements.

- Positive Material Identification (PMI) Testing: PMI testing is conducted to verify the material grade and composition of the Inconel 601 tubes. This testing ensures that the tubes are made from the correct alloy and meet the desired material specifications.

- Flattening Test: The flattening test evaluates the ductility and formability of the Inconel 601 tubes by subjecting them to controlled deformation. This test ensures that the tubes can withstand bending and flattening without failure.

- Micro and Macro Test: Micro and macro tests involve examining the microstructure of the Inconel 601 tubes to assess their internal integrity and grain structure. These tests provide insights into the material’s resistance to corrosion, cracking, and other forms of degradation.

- Pitting Resistance Test: The pitting resistance test evaluates the resistance of the Inconel 601 tubes to localized corrosion, such as pitting and crevice corrosion. This test ensures that the tubes can withstand corrosive environments without significant degradation.

- Flaring Test: The flaring test assesses the ability of the Inconel 601 tubes to withstand flaring without cracking or failure. This test ensures that the tubes can be easily formed and connected in various applications.

- Intergranular Corrosion (IGC) Test: The intergranular corrosion test examines the susceptibility of the Inconel 601 tubes to intergranular corrosion, which can occur in certain environments. This test ensures that the tubes have good resistance to intergranular corrosion.