EN 10305 (E215, E235, E335) Welded Steel Cold Drawn Precision Pipe

November 16, 2025

Heavy Wall Thickness SCH 160 Seamless Steel Pipe

November 28, 2025The Armored Conduit: Engineering Structural Integrity and Filtration Precision in the 4-Inch Pipe-Based V-Wire Well Screen

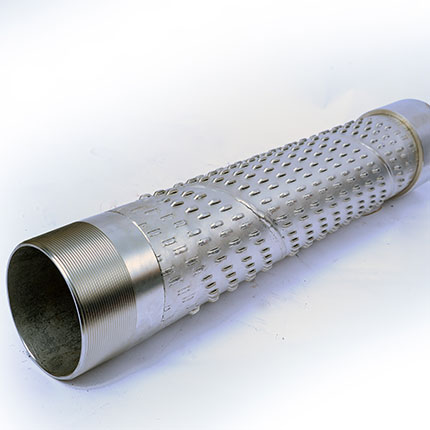

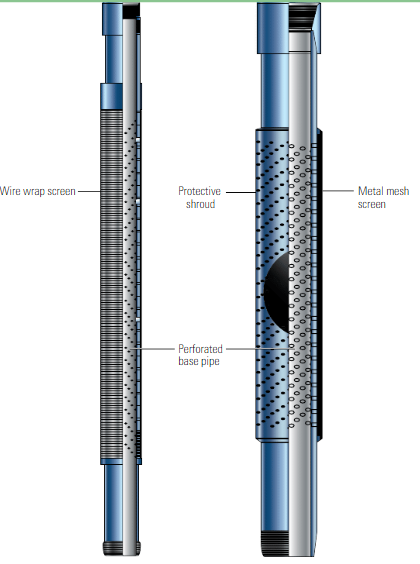

The perennial challenge in the extraction of subsurface fluids—whether oil, gas, or water—is the necessary balancing act between achieving high-volume production and preventing the catastrophic ingress of formation sand and fines. While standalone well screens offer effective filtration, their mechanical limitations—particularly their susceptibility to collapse under deep well pressures or failure under high tensile loads during installation—render them unsuitable for the most challenging energy and mining applications. This structural deficiency is precisely what the Pipe-Based Well Screen is designed to eliminate. Specifically, the 4-Inch Pipe-Based Twin Layer V-Wire Screen represents a high-integrity, composite engineered solution where the robust mechanical envelope of an API-certified casing or tubing is seamlessly married to the sophisticated filtration geometry of the Johnson (V-Wire) jacket.

This design methodology transforms a purely passive filter into an active, pressure-retaining conduit. The use of a standard API Casing Base Pipe—often a $4 \text{ inch}$ nominal size for monitor wells, high-pressure water wells, or slim-hole production—provides overwhelming collapse, burst, and tensile strength, guaranteeing safe deployment in deep, high-deviation wellbores. Simultaneously, the outer V-Wire screen provides the continuous slot aperture necessary for maximum flow and precise sand exclusion, while the perforated base pipe acts as a second, coarser filtration layer and a protective shield for the V-Wire jacket itself. The material spectrum, ranging from economical Q235 carbon steel to highly corrosion-resistant 316L stainless steel, allows the final product to be meticulously tailored to the specific chemical environment of the reservoir, creating a final engineered component that sacrifices neither structural security nor long-term filtration efficacy.

1. The Composite Filter Imperative: Structural Security and Flow Dynamics

The Pipe-Based Screen is not simply two components bolted together; it is an integrated system designed to overcome the structural fragility of conventional screens. The design philosophy centers on utilizing the base pipe’s mechanical superiority while ensuring the filtration layer’s exposure to the formation is maximized.

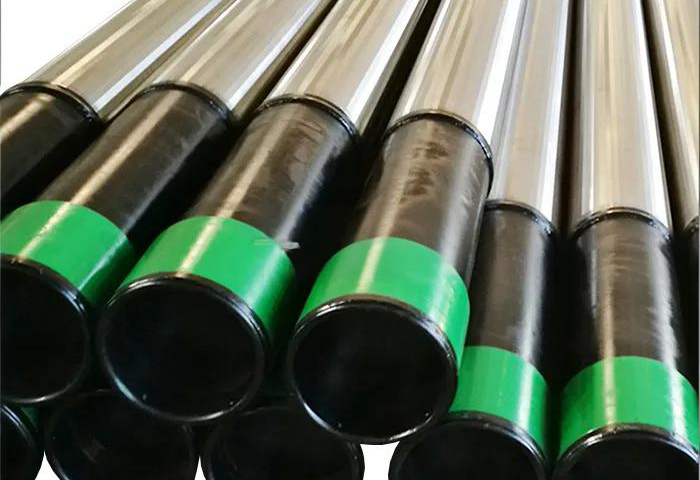

The Indispensable Role of the API Base Pipe

The primary function of the internal base pipe—typically API 5CT casing or tubing—is load bearing. The perforated pipe must retain a high percentage of its original Collapse Strength to withstand external pressure from the cement, overburden, or annular fluids, especially in deep wells where pressures can exceed $50 \text{ MPa}$. Furthermore, the pipe’s threaded connections (STC, LTC, or BTC) must maintain integrity under high Tensile Load during the running-in process, particularly in long, directional, or horizontal sections where drag is substantial. By utilizing API-grade material (e.g., J55, N80, L80), the engineer is guaranteed a quantified, traceable level of mechanical performance, which is a non-negotiable requirement for regulatory compliance and operational safety in high-pressure oil and gas environments.

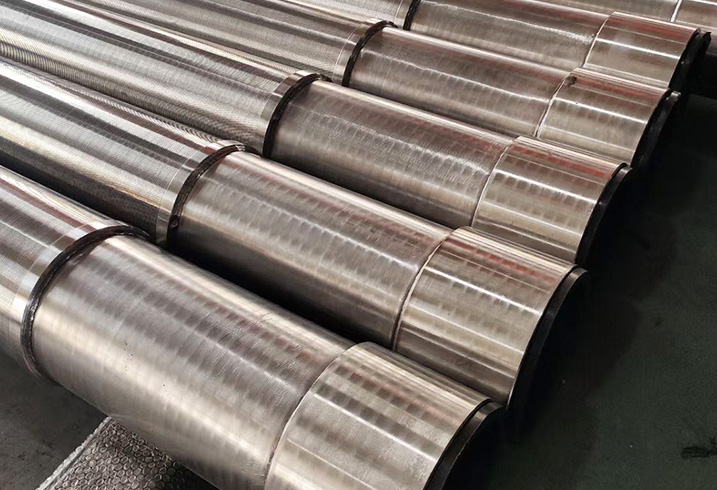

The V-Wire Jacket: Precision and Anti-Clogging Geometry

The outer layer, the Johnson Type V-Wire Screen, provides the necessary filtration precision that the perforated pipe alone cannot offer. It is constructed by helically winding a V-shaped profile wire onto longitudinal support rods. This geometry ensures:

-

Continuous Slot: Maximizes the open area, minimizing the fluid entry velocity and thereby reducing the localized pressure drop, which is critical for minimizing the risk of fine particle migration and formation skin damage.

-

Non-Plugging Aperture: The V-shaped wire creates a slot that is narrowest at the external face and widens inwardly. Any particle that passes the external face cannot become lodged within the slot; it must pass entirely through into the perforated pipe. This property is paramount to maintaining the long-term flow efficiency of the screen.

The composite structure ensures that the high-precision V-Wire filtration layer is always protected by the perforated steel conduit during handling and downhole deployment, while the base pipe’s mechanical integrity is minimally compromised.

2. The Structural Foundation: API Base Pipe Specifications and Geometric Modification

The precise specifications of the base pipe, particularly its material grade, wall thickness schedule, and connection type, dictate the ultimate mechanical envelope of the finished screen. For a $4 \text{ inch}$ nominal screen, the pipe dimensions fall into standard API casing or tubing sizes, ensuring compatibility with established downhole tools.

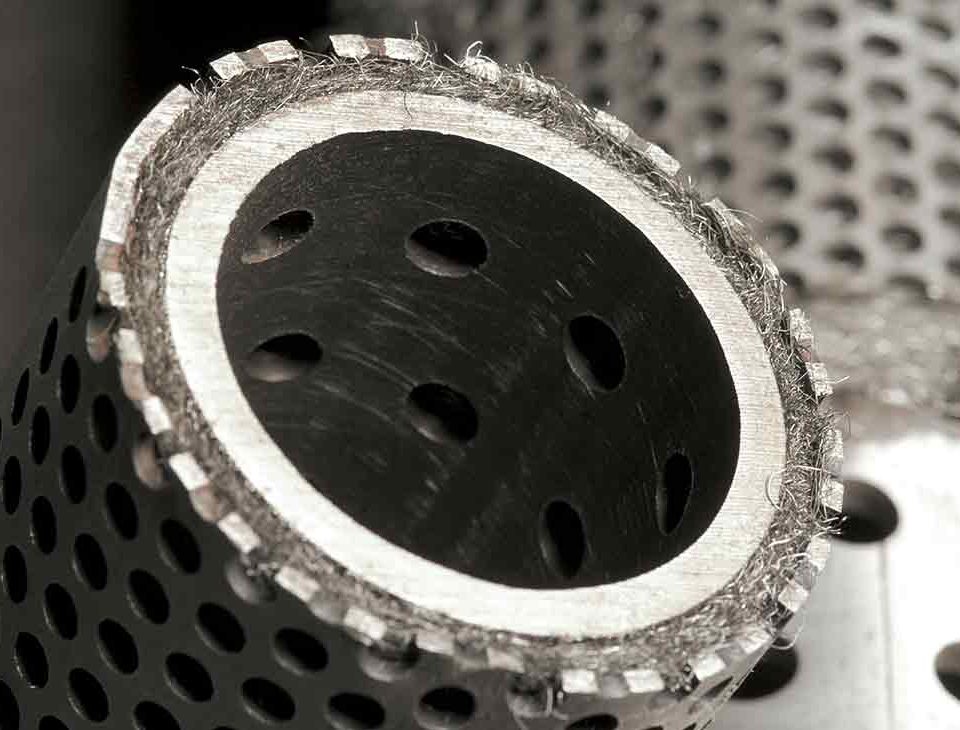

Perforation: The Trade-Off Between Flow and Strength

The base pipe is transformed into a functional filter by the process of perforation (drilling or punching numerous holes). This process is the critical point of compromise in the design:

-

Perforation Open Area (POA): The total area of the holes must be maximized (e.g., $15\%$ to $30\%$ POA) to ensure the perforated pipe does not become the dominant flow restriction (choke point) in the system. The total flow capacity should be dictated by the V-Wire slot geometry, not the base pipe holes.

-

Remaining Wall Strength: Each perforation, however, removes load-bearing metal, reducing the pipe’s original collapse and tensile strength. The perforation pattern—size, spacing, and density—must be meticulously engineered to ensure that the remaining wall strength (the “ligament efficiency”) still meets the minimum safety factors required for the maximum expected external pressure and tensile load during installation.

The standard for these pipes adheres to API Specification 5CT, which mandates strict tolerances on outer diameter (OD), wall thickness (WT), and material properties (Yield and Tensile Strength).

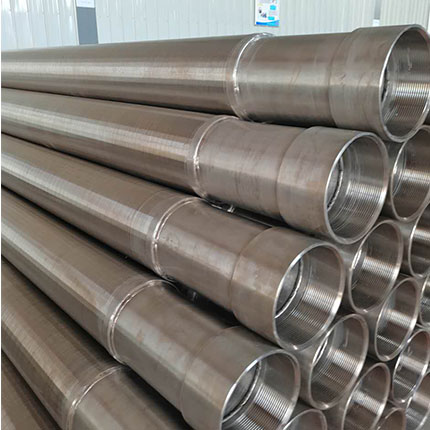

Connection Integrity: STC, LTC, and BTC Threads

The method of joining screen segments is as critical as the pipe body strength. The use of API standard casing threads—Short Thread Coupling (STC), Long Thread Coupling (LTC), or Buttress Thread Coupling (BTC)—provides quantifiable joint integrity:

-

STC and LTC: Primarily used for tensile loading, offering a robust mechanical connection but relying on thread engagement for sealing. LTC is preferred for deep wells due to its longer thread engagement and higher tensile capacity.

-

BTC: Characterized by its unique thread form, which offers superior resistance to burst pressure and compression loading, along with excellent sealability due to the sharp-crested threads and the coupling shoulders. BTC is the standard for high-pressure completions where seal integrity under complex load conditions is paramount.

The screen jacket and base pipe are precision-welded together at the coupling area to ensure the V-Wire jacket remains secured to the structural component, preventing relative movement or damage during running.

| Parameter | Specification / Requirement | API Casing Base Pipe (L80 Example) | Tolerance of Thickness Schedule |

| Primary Standard | API Spec 5CT (Casing/Tubing) | ASTM A510 / API 5CT (Pipe) | Wall Thickness $\pm 12.5\%$ of nominal WT |

| Material Grade | API 5CT L80 (Sour Service Qualified) | Carbon-Manganese Steel (Controlled Hardness) | N/A |

| Heat Treatment | Quenched and Tempered (Q&T) | Required for strength and hardness control (NACE compliance) | N/A |

| Tensile Strength | Min $R_m = 655 \text{ MPa}$ ($95 \text{ ksi}$) | Min $R_{eH} = 552 \text{ MPa}$ ($80 \text{ ksi}$) | N/A |

| Nominal Size | 4 Inch (OD $114.3 \text{ mm}$ for $4-1/2 \text{ inch}$ Casing) | Standardized API Dimension | Outer Diameter $\pm 0.79 \text{ mm}$ |

| Connection Type | STC, LTC, or BTC | Threaded API Connection | API Spec 5B Tolerance |

3. The Metallurgical Spectrum: Matching Material to Corrosivity

The requirement for the Pipe-Based Screen to function in diverse environments—from non-corrosive groundwater wells to sour, high-chloride oil fields—necessitates a range of material options for both the base pipe and the V-Wire jacket. The selection is a critical decision based on a cost-versus-corrosion-risk analysis.

Carbon Steel (Q235) and Standard Stainless (304/201)

-

Q235 (Chinese Standard): Functionally equivalent to ASTM A36/A283. This is an economical, low-carbon steel suitable for non-corrosive environments such as shallow or freshwater wells where the primary threat is mechanical damage and simple oxidation, not chemical attack. It is fundamentally unsuitable for high-chloride or sour service.

-

304/304L (Standard Austenitic Stainless Steel): Provides basic resistance to general corrosion and is often used in clean water wells or low-concentration $\text{CO}_2$ environments. The low-carbon variant ($304\text{L}$) is preferred in welded applications to minimize intergranular corrosion (IGC). However, 304/304L offers poor resistance to chloride-induced Pitting Corrosion and Stress Corrosion Cracking (SCC), ruling it out for aggressive brines.

High-Performance Stainless Steel (316/316L)

The move to 316/316L Stainless Steel is the industry standard for environments with moderate chloride concentration.

-

Molybdenum Advantage: The key difference is the addition of $2\%$ to $3\%$ Molybdenum ($\text{Mo}$). Molybdenum significantly boosts the material’s Pitting Resistance Equivalent Number (PREN), which is the quantifiable measure of resistance to chloride pitting. This makes 316/316L far more durable in brackish water, seawater, or moderately salty oilfield brines than 304L.

-

SCC Mitigation: While susceptible to SCC at high temperatures, 316L is the minimum requirement for many corrosive oil and gas applications where corrosion inhibitors are utilized to manage the remaining chemical risk.

The metallurgy of the V-Wire Jacket must be equal to or higher than the base pipe’s corrosion resistance, as it is the component exposed directly to the untreated formation fluid. Using a 316L jacket on an API L80 base pipe is a common configuration that balances structural integrity with environmental resilience.

| Material Grade | Primary Application | Chemical Characteristic | Key Corrosive Risk Addressed |

| Q235 | Shallow/Fresh Water Wells, Non-corrosive Mining | Low Carbon Steel, High Weldability | Mechanical Strength, Basic Wear |

| 304 / 304L | Clean Water, Low-Chloride Applications | Austenitic Stainless Steel (Cr 18%, Ni 8%) | General Oxidation, Atmospheric Corrosion |

| 316 / 316L | Brackish Water, Oil/Gas (Moderate Chloride) | $\text{Mo}$ Addition (2-3%), $\text{Cr} 16\%$, $\text{Ni} 10\%$ | Pitting Corrosion, Crevice Corrosion (due to $\text{Cl}^-$) |

4. Specification, Features, and Application Synergy

The final product specification integrates the mechanical integrity of the base pipe with the geometric requirements of the V-Wire jacket, ensuring that all aspects of the downhole operation are supported.

V-Wire and Overall Dimensional Tolerances

The most crucial tolerance for the V-Wire jacket is the Slot Width and the OD/ID relationship.

-

Slot Width Tolerance: Must be precise (e.g., $\pm 0.05 \text{ mm}$) to ensure accurate sand exclusion and prevent fine particle migration, which is the definition of sand control failure.

-

ID/OD Coupling: The inner diameter (ID) of the V-Wire screen jacket must precisely match the outer diameter (OD) of the perforated base pipe to allow for secure welding and prevent the ingress of solids between the two layers, which would lead to internal abrasion.

The final assembly’s OD must also adhere to tight tolerances to ensure smooth passage through the existing casing string (the running clearance).

Application Versatility and Key Features

The $4 \text{ inch}$ Pipe-Based V-Wire Screen is deployed across diverse industries due to its robust design:

-

Deep Water Wells: Where the head pressure is high and the integrity of the screen against collapse is vital.

-

Oil and Gas Production: Used in non-gravel-packed stand-alone screen (SAS) completions in moderately consolidated reservoirs, or as the component in frac-pack operations, where the screen must withstand high injection pressures.

-

Mining and Geothermal: Used for dewatering and injection wells where the structural integrity is challenged by directional drilling and the corrosive fluid chemistry often mandates the use of 316L or higher alloys.

| Feature Category | Descriptive Feature | Engineering Justification |

| Structural Integrity | API 5CT Casing Base Pipe (Q&T Steel) | Guarantees high Collapse, Burst, and Tensile Strength for deep/directional wells. |

| Primary Filtration | Johnson V-Wire (Continuous Slot) | Provides high open area and non-plugging aperture for precise sand control. |

| Flow Conduit/Protection | Perforated Base Pipe | Acts as the main flow path and protects the V-Wire jacket from internal tool damage. |

| Connection Security | API BTC/LTC Threaded Connections | Ensures pressure seal and mechanical joint integrity under extreme tensile loads. |

| Corrosion Resistance | 316L Stainless Steel Option | Molybdenum content defeats pitting corrosion in chloride-rich brines. |

| Installation Ease | High Rigidity | Easier to run in high-deviation or horizontal sections than flexible standalone screens. |

A Synthesis of Strength and Precision

The 4-Inch Pipe-Based Twin Layer V-Wire Well Screen is a technically superior engineered product that directly addresses the limitations of conventional sand control techniques in demanding subsurface environments. Its design is a calculated synthesis: the mechanical envelope of the API-certified base pipe ensures structural longevity against collapse and tensile failure, while the V-Wire jacket ensures continuous flow and precise particle size exclusion. The ability to select from a spectrum of materials, from Q235 for basic applications up to 316L for corrosive brines, allows for precise cost-benefit optimization based on the geological and chemical risks of the specific well environment.

By unifying structural strength with filtration efficiency, the Pipe-Based Screen moves beyond simple filtration; it is an armored conduit designed to be the robust, reliable interface that sustains high-rate, sand-free fluid production over the multi-decade life cycle of the well, ensuring the safety of the wellbore and the profitability of the resource asset.